Print defects can come in many shapes or patterns. Both offset and inkjet can have print defects, no print process is perfect. Offset printing can cause picking or other issues such as offsetting, ghosting, graininess, and poor registration because of the ink being applied by pressure to the paper.

On the other hand, inkjet printing can introduce jet outs, deviated jets, cross process density shifts as well as offsetting or picking because it sprays the ink from a print head above the media surface. There are a couple of problems that are unique to jetting, but most defects can happen in either process as show below

|

Offset and Inkjet both experience: |

Issues only with Inkjet: |

|

|

Offset and inkjet are completely different print processes but can indeed experience some of the same issues.

In a previous article we covered color differences and the importance of targeting a similar color space when comparing offset color to inkjet, but print characteristics go beyond just color. To fully understand the differences, print defects must also be addressed and measured. To avoid turning this article into a book, we will be focusing on the print quality concerns which inkjet introduces for conventional offset printers moving to inkjet. We will review measured examples of three key areas, graininess, uniformity and jet-outs in a series of posts and provide helpful advice. Today we lay the foundation of our measured examples and talk about graininess.

Process Review – Comparing Offset and Inkjet for Graininess

For comparison purposes, our Reference-Offset is a Cold Set process utilizing a sheet-fed MAN Rolland with a direct to plate (DTP) process at 200 line screen and our Sample-Inkjet is a continuous roll to roll, Primer+CMYK ink set utilizing variable drop which ranged from 3-8pL respectively. Tests were produced at 262fpm at a resolution 1200×1200 with both processes conducted at the same location. The tested media were 70# UPM Endurance for offset and 70# UPM Finesse Gloss. Printing was targeted to CRPC6 GraCol 2013.

Graininess

Inkjet uses a dither pattern otherwise called stochastic or FM screening. This technique is designed to fake the eye into thinking an ink has been screened back by spreading drops farther apart (mid-tones and highlights) or closer together (3/4 tones and solids). This technique can leave highlight areas and flesh tones looking grainy, particularly when compared under a loop.

Mostly seen in printed halftones areas, graininess is a print characteristic seen when a printed color is formed with dots or drops that are not adequately randomized, resulting in a speckled pattern. Graininess is different from mottle. Mottle appears larger and is characterized by uneven, irregular blotches or patches of varying saturation caused by uneven ink drying or paper formation/absorption.

Offset uses a different screening process than inkjet called AM screening which produces a Rosette pattern. This pattern is created when the screened film for each process color is produced at different angles. Rosette patterns smooth out highlight areas as your eye is not focused on a dot, but a pattern.

In the images below you will see that offset and inkjet each perform better in certain areas and worse in others.

Image B: FM Screening = Dither Pattern

Magnification ~ 2.5µm/pixel

Measuring Graininess

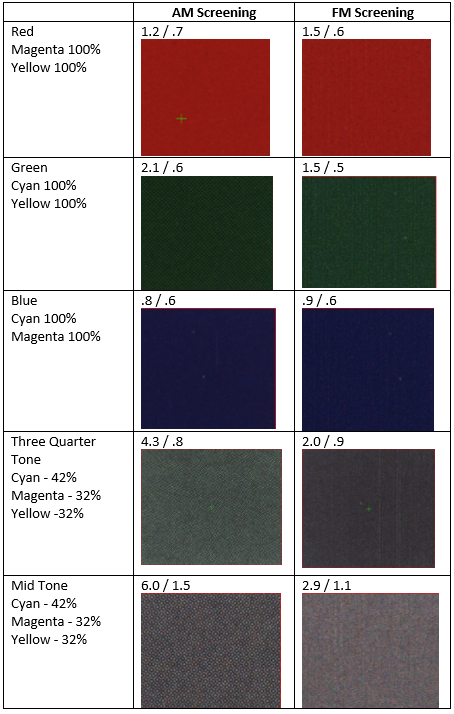

To measure graininess properly, 200% solid colors in various tones should be included in the test. The chart below shows graininess measurement as it correlates to a visual sample using secondary and gray value color mixtures for both offset (AM Screening) and inkjet (FM Screening.)

The measurements below show both graininess and mottle measurement. Graininess, which is a speckled appearance in which dots stand out by themselves and not as a pattern. Graininess metrics correlate well with visual perception of image noise. To minimize human sensitivity, measured print graininess should measure <4.0 respectively to lessen the granular micro-contrast deviation which correlates visual disturbance sensitivity. Mottle on the other hand is not a graininess, but a larger macro-contrast deviation shown as larger areas visual spotchiness.

Image C: Graininess/Mottle CMY gray measured using ISO-13660 Area Specification. A lower image capture of 17µm/pixel is used to represent viewing distance to how it correlates with disturbance.

The red, green and blue solid blocks above show, for both inkjet and offset, graininess values which are equal or under target as solids mixed at higher color density values show less graininess when color has low contrast between the printed color and the white point of the paper.

For the tone values, we see a larger graininess value for the AM Screening than the inkjet in the quarter, mid and three-quarter tone values. This is just the opposite from the red, green and blue measurements above, each process gray value patterns becomes more apparent to our measurement readings as more of the white point of the paper begins to become apparent. As the rosette pattern reduces in ink value, the pattern itself does not reduce in size and begins to appear more apparent to the eye. Inkjet fairs better in graininess in the three-quarter and mid tone areas as drops are mixed in common mid-drop sizes which are smaller than the size of offsets rosette pattern. For inkjet quarter-tone areas which are used for highlight (which we are most visually sensitive to), the size of the smallest drop is critical as the drops placed in a wider dither pattern increases visual sensitivity to the dot as the drops no longer create a random pattern but begin to scatter randomly.

Since this study was printed on high hold out coated paper, the mottle values measure way within the target range as the uneven ink spread causes by paper absorption or coalescence is not a factor with these two processes in this study.

When looking at inkjet print quality compared to offset, a visual dot can be perceived as lower quality. To tackle the highlight graininess effect, OEMs are integrating smaller drop print heads with variable drop sizes, softening the dot appearance, especially within mid-tones to highlight areas. Adding smaller and variable drop sizes are creating a smoother appearance in inkjet than offset in the highlight and mid-tone values.

When looking at inkjet, be sure to understand the differences in the printheads, resolution, native drop sizes (pL) and the drop per dot offered (DPD).

Image D: AM Screening = Rosette Pattern

Image E: FM Screening = Dither Pattern

Magnification ~ 17µm/pixeI

Each process has its own set of considerations when it comes to the comparative argument of graininess. Over time, inkjet has integrated print heads which lower the visual disturbance of graininess in print areas by moving to variable drop or multi DPD print heads reducing the medium and smallest drop sizes used for the most sensitive areas of mid-tone and quarter-tone ranges.

If you appreciate, unbiased measured comparisons of technology you may also want to look the recent very candid comparison of toner and inkjet technologies in this white paper on the graphic arts segment. Check back for my next post covering offset, inkjet and uniformity.