One of the fastest-growing applications in wide-format and industrial printing is textures. Particularly in the area of décor, items like laminate flooring can be printed to simulate the feel of wood. But the correct depth and detail is required.

Personally working within the industrial inkjet space, I have needed to create imagery to jet on many different types of substrates and finished products, but when trying to achieve natural life-like detail and depth for wood grains and marble, flat bed scanners did not capture the detail needed for quality reproduction in printed form.

While a lot has been written about how these kinds of materials are printed, typically using UV single pass or flatbed printers, not much has been said about the front end of the required process when developing inkjet imaged home décor such as flooring and window covering.

When tasked with a project to develop 34’ seamless, highly detailed, wood grain images for single pass inkjet home décor products (which were to be viewed at eye level) I needed reproductions which were flawless.

Enter METIS.

Based in Rome, Italy, METIS manufactures high-quality, multi configuration scanners specifically designed for the décor industry. They can capture a photorealistic reproduction of an existing surface such as a fine-art painting, wood or ceramic/stone flooring, a solid panel, or a wall covering.

The Metis Technology was used in the design of this flooring AND to generate surface data in this computer-generated room scene displaying the product.

I had the pleasure to collaborate with Rob Lawrence, Business Development Manager for Metis scanners at CGS –ORIS on this project. CGS ORIS is the official dealer for METIS scanners in the USA.

“METIS scanners are considered to have the highest level of color accuracy across the largest area and over the course of time of any commercially available RGB scanner in the world today,”

“Additionally, METIS is wholly unique in the image acquisition process, and brings an exceptional level of objectivity to the imaging process which is one of the key reasons it was brought into the product offering at CGS ORIS.”

Project Development with METIS

The project required scanning 9 different 4’ finished wood slats; and as organic materials go, each not a true grain continuous pattern of the previous. The project required a seamless stitch to create a continuous 34’ Adobe Photoshop file. Choosing slats for capture with a high level of natural grain detail was important, as it is easier to remove grain pattern than develop it.

My first step was to ensure the wood slats provided more detail than required, as the grains would be separated and merged to different background colors. Having more detail allowed the grain detail to show through even on dark colors. Sanding and finishing the wood correctly ensured the grains would produce the right 3D surface texture.

Finished wood slats were scanned for surface attributes of RGB color, 3D surface texture, and glossiness; which is what METIS scanners are uniquely designed to do.

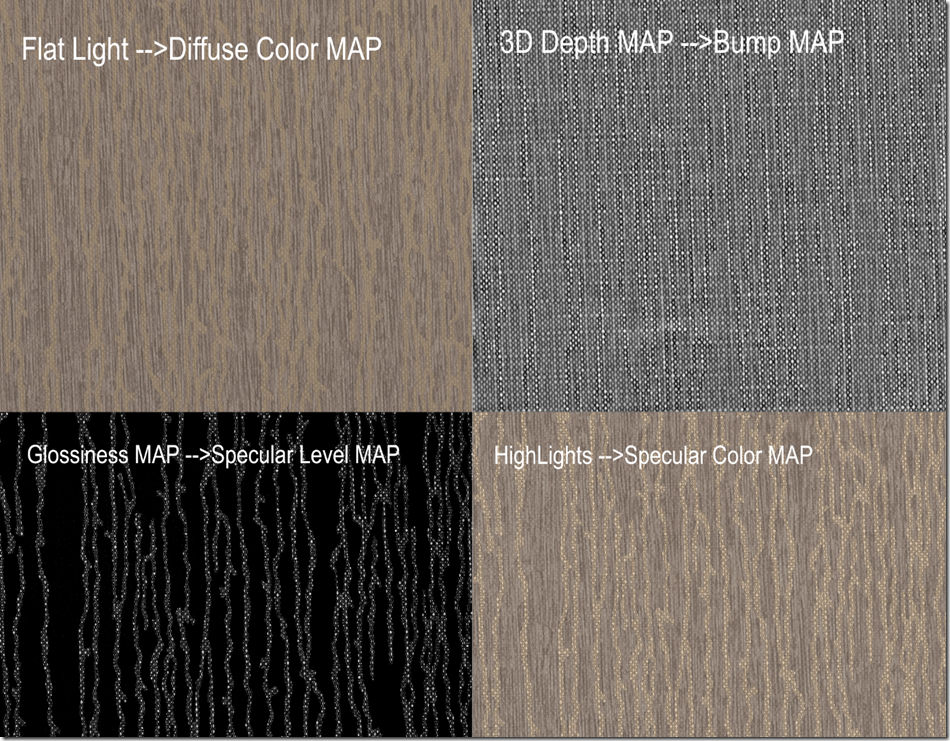

High-Res Image Capture sectioned to show surface texture and gloss options

I chose METIS scanners for this project because their technology is different from traditional flatbed scanners. They scan the surface with a 16,300-pixel CMOS sensor and temperature-controlled LEDs, up to eight times, each with tightly controlled angle and distance. The captured data is saved into a proprietary file format. Once captured, METIS’s Light Inspector software acts like a virtual photography studio where the operator views, in real time, a virtually unlimited number of lighting combinations to select the view of the surface that best represents the original. In addition, because of these known lighting angles, distances, and temperatures, the METIS software will isolate and calculate the 3D surface depth and surface roughness/glossiness variance.

This data can be then exported as grayscale Adobe Photoshop editable TIFFs (16-bit, 8-bit, 8-bit layers, 1-bit, and/or 1-bit slices) which can be used for laser and chemical etch engraving of press plates and gravure cylinders, or single-pass and/or multi-pass UV inkjet printing and embellishment applications.

Specialty texture mapping offers various possibilities

Hardware also needs software, and each METIS scanner comes bundled with METIS’s ScanDirector, which controls the scanning process with all the controls needed for the most advanced photography requirements. Both applications share the same user interface and work interchangeably. METIS also offers additional licenses of Light Inspector for remote computers, which can be a tremendous benefit to a designer in a different location who wishes to select the lighting angle intensities to capture the nature/essence of the surface they chose for a specific design.

As Rob and I collaborated on this project from different parts of the country, Light Inspector was a crucial aspect of the project as it created a remote viewing. Each wood slat required a few different light source captures that could be used for layering when wood slats did not match naturally when combined to 34’. We collaborated remotely visualizing the light angles in real time.

Once the scans were complete, I had various levels of 3D surface dimension grain levels to work with, allowing various layers and depth levels to be modified if slats did not have the imagery required for a natural continuous grain. Although, Photoshop image development was needed for stitched 4-foot end to end sections, no additional grain detail was required.

METIS developed detailed splices of a wood scan

Everything—Including the Kitchen Sink

After the project was finished, Rob and I had some time to talk more in depth. I was impressed with the process and had to ask about METIS scanners and the unique variety of the surfaces they can capture.

“With heavy-duty powder-coated steel scanning tables, the scanners can hold over 500 pounds,” says Lawrence. “But with integrated sensors, the scanners can be adjusted to detect the slightest weight change and resistance allowing the most delicate originals to be scanned without danger of being damaged by the scanner.”

Some examples of materials scanned at METIS’s demo center include a whole kitchen sink (!), 500-pound granite slabs, barn doors, white glazed tiles, oiled asphalt, oil, acrylic and watercolor paintings, grand-format maps, denim, wallpaper, and a host of other kinds of textiles.

Got mud? No Problem with the METIS DRS 2000 DCS Large Format Scanner

And the coolest thing anyone has scanned and developed with a METIS scanner?

“A fashion house in Milan scanned the wings of a preserved falcon and used the pattern to emboss the shoulders and sleeves of a leather jacket,” says Lawrence. METIS clients aren’t afraid to get their hands (or feet) dirty—literally. “We had one client lay mud on the table for a textile design,” says Lawrence.

Given the variety of materials and surfaces the scanners can digitize, they are well-suited for a wide range of markets. The three primary markets that the company specifically serves are décor (flooring, wall panels, wall coverings, and ceramic tiles), fine-art reproduction, and archival services (libraries and museums). Naturally, each of these markets has different imaging requirements. “Depending on the market, the desired resolution, and if they plan to reproduce texture and glossiness will determine the kind of output required from the scanner,” says Lawrence.

Market Dynamics

All markets have their own dynamics. “Decor is undergoing a transformation to a digital workflow,” says Lawrence. “With digital will come a huge demand for more depth. The METIS scanner is a high throughput scanning technology equipped to deliver all of the needed data and files for the latest digital printing technologies which include the ability to generate surface texture and glossiness for embellishment or texture builds.”

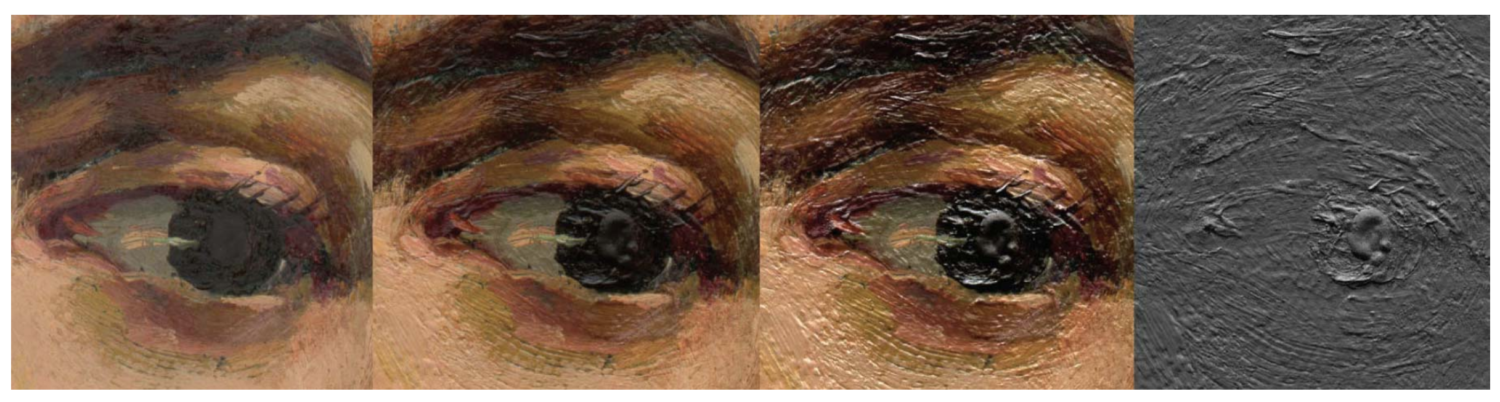

For the fine-art market, some of the benefits that the METIS scanner offer is similar, but there are some unique requirements for this market. “The ability to capture and reproduce an original work of art with a printing process requires not only an ability to accurately reproduce a painting, but also an adept understanding of the artists they serve,” says Lawrence. “The METIS gives the fine-art professional a tool to start off with the most complete and accurate capture, and combines it with a scanning methodology and software tool to work with the artist side-by-side to capture the true essence of the original in real time.” The scanner can also export accurate surface texture and glossiness details in formats unique to each printer’s unique capabilities such as ink thickness per pass, as well as the ability for the RIP to lay down individual layers to build up the surface height.

Oil painting scanned with texture levels in RGB with gloss mapping image

For archival services, it’s all about capturing detail and consistency. “The METIS scanners were designed to provide the highest level of light uniformity and detail for the most challenging originals,” says Lawrence. “METIS flatbed scanners are among the rare elite scanners capable of achieving a FADGI 4-Star designation, the highest quality standard in the archival industry.”

Some specific METIS customers and the kinds of tasks to which they are putting the scanner include:

- The world’s best-known tile manufacturers and retailers use the METIS to generate original designs and to create their marketing imagery for catalog and online content.

- The décor manufacturers in the US are using the METIS to reduce time, costs, and ultimately product returns by generating more effective sample materials.

- Fine art reproduction houses are using the METIS to produce higher-quality images for 2D giclée’s, as well as 3D textured fine art reproductions produced on a flatbed UV printer.

- Colorimetry for hard to color manage printed media such as ceramics, wood, concrete, and carpeting.

Working with METIS on this project created a sense amazement of what we can capture and apply to inkjet printing; creating reproductions that look, feel and reflect like the original.

More information can be found at CGS ORIS (www.cgsusa.com) and at METIS-Group, Italy (www.metis-group..com)