Ten years ago, the term production inkjet was intended to distinguish high-speed, single-pass inkjet presses from desktop, departmental, and wide-format inkjet devices. Not stated was that production inkjet was primarily used to produce documents like customer communications, books, and direct mail with a bit of signage if you had a B2 sheetfed press.

Flash forward and high-speed, single-pass inkjet is producing packaging, textiles, and other industrial applications typically assigned their own inkjet categories. The production inkjet category continues, accurately or not, to refer to document-related applications. The terminology can be a bit puzzling.

Marco Boer of I.T. Strategies notes “We define [production inkjet] strictly as document printing. We keep all the other market separate.” He cited 13 subcategories of overall inkjet printing with total OEM revenues for hardware ink and service estimated at US$16.3 billion in 2022 and growing to US$24.5 billion by 2028. Of that total revenue, about 14% (2.3B) relates specifically to the production inkjet category with a projected 13% compound annual growth rate bringing revenues to 4.7 billion and 19% of the total, overall inkjet OEM revenues.

Tim Green of IDC also confirms that their “IDC MarketScape for High-Speed Inkjet” sets a strict definition around the document segment to avoid confusion. He advises, “Certain high-speed inkjet machines simply should not be compared to others as one may not be an appropriate replacement for, or alternative to, the other. I think looking at a press like the Xerox Baltoro and comparing it to a press like the HP C500 is like comparing a Honda Civic to a Ford F-250—both are vehicles/high-speed inkjet-based presses, but they’re made for different things.” While printing companies might consider branching out from the document space into aspects of packaging, it is not reasonable to compare a B3 sheetfed press serving the document market to one that prints on corrugated media of 98 inches in length.

Even when limiting the production inkjet discussion to the document market, the capabilities and formats of the presses under this umbrella have expanded dramatically with varying widths of continuous-feed presses as well as several different sheetfed formats. Applications confidently span from monochrome and color customer communications to photo-quality graphic arts production with some presses nudging into the lanes for signage and even some types of packaging. This article will focus on the latest production inkjet models including new press introductions from 2023 and products announced previously that became commercially available or had their first installations this year.

A Slow Start with a Frenzied Fourth Quarter

Early 2023 activity centered around continuous-feed graphic arts presses demonstrated at Hunkeler innovationdays (HID) in Lucerne, Switzerland. HID showcased the Kodak Prosper Ultra 520 HD for the first time outside of their customer center and the HP PageWide Advantage 2200 for the first time outside the US. Kodak showed samples from the PROSPER 7000 Turbo which became commercially available in 2023. Canon launched the ProStream 3000 series at HID with full commercial availability within three months.

The next series of launches clustered in October with a focus on sheetfed presses. All can be characterized as technology previews except for the long-awaited Ricoh Pro Z75 B2 press which was previewed with select analysts in 2018, publicly announced in 2020, and became commercially available in November 2023. The remaining presses are A3/B3 format devices from Canon, Kyocera, and Screen with commercial availability ranging from mid-2024 into 2025.

Canon previewed the varioPRINT iX1700 B3 press at Canon Expo in Yokohama, Japan. PRINTING United hosted Kyocera’s announcement of the TASKAlfa 55000c and the cooperation of Screen and Kyocera on the Screen Truepress JET 520. It’s notable that all these presses, rollfed and sheetfed alike, are focused on the highly demanding graphic arts segment.

Rolling Out the Rollfed Presses

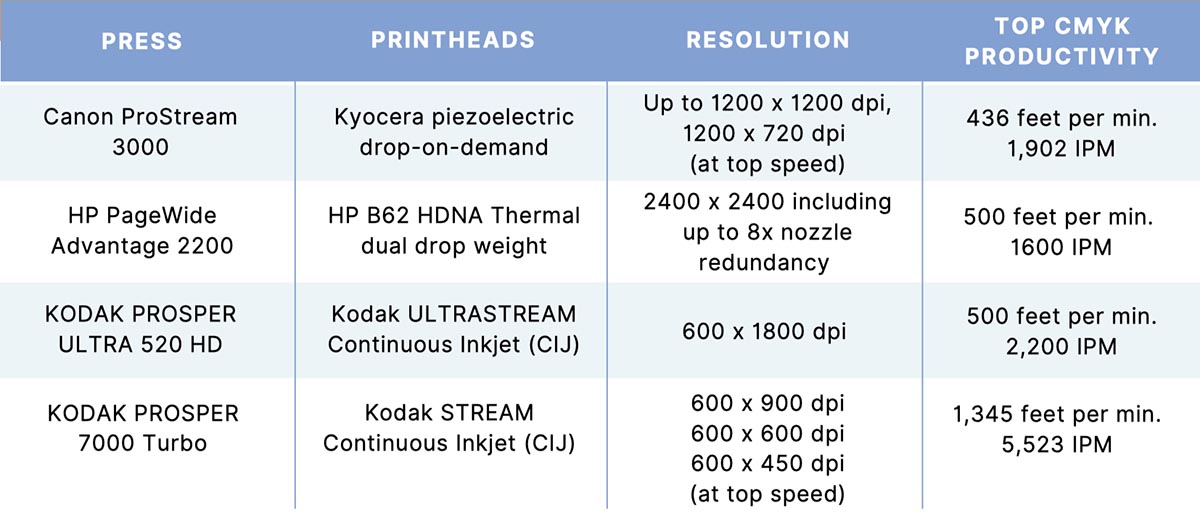

Below is a quick summary of the latest continuous-feed press launches highlighting the different approaches to serving graphic arts segment. Piezoelectric, thermal, and continuous inkjet printing technologies are all represented with differing native resolutions (which must be considered in the context of the number of drop sizes generated and the size and consistency of those drops.) All the widths are 2-up roll except for the Kodak Prosper 7000 Turbo which handles paper up to 25.5 in. wide.

Table 1. The Latest Roll-fed Inkjet Press Launches

Sheetfed Inkjet Accelerates

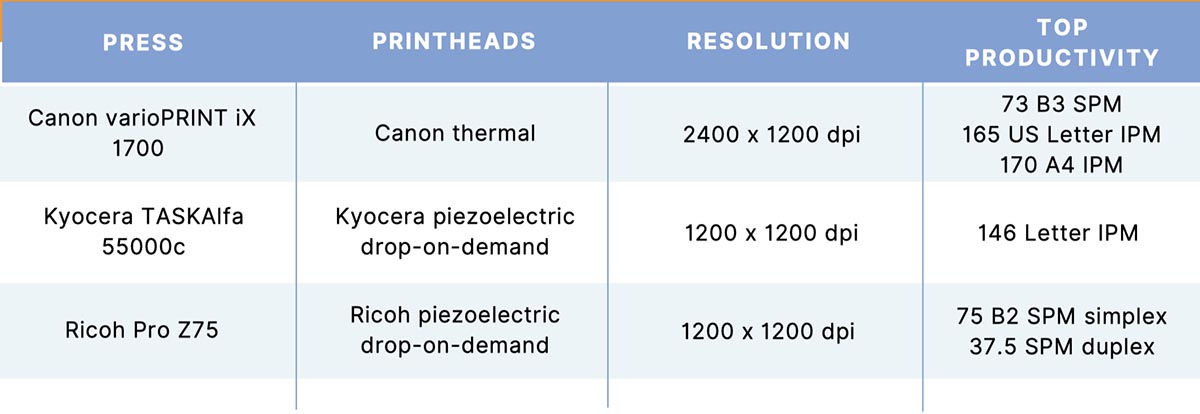

ISO 216 includes A, B, and C series paper formats measured in millimeters. The US typically refers to formats such as US Letter, Legal and Tabloid sizes measured in inches. For purposes of this article, we refer to a presses’ format as the closest B sheet size. Productivity is reported in sheets (SPM), letter images, and A4 images per minute (IPM) where available.

Like the rollfed entrants, the newest sheetfed presses show an array of approaches for targeting the graphic arts segment. The summary table below shows a variety of strategies for meeting graphic arts requirements with the Canon and Kyocera presses aimed at making these capabilities accessible to a wider range of buyers through lower investment cost and smaller footprints. Screen announced their collaboration with Kyocera on a version of the TASKAlfa 55000c to be launched in 2025, dubbed the Truepress JET S320. This will provide a complement to Screen’s existing rollfed graphic arts presses. Please see “Meeting the Graphic Arts Printing Needs of Smaller Enterprises” below for a deeper dive into the Kyocera sheetfed capabilities.

Table 2. The Latest Sheetfed Inkjet Press Launches

Before we provide further details on each of these presses, I would like to point out that every single one of them will print on offset coated stocks. Some use a precoat to accomplish that goal while others don’t, but we can clearly say that coated stocks are no longer inkjet’s kryptonite.

Let’s Take a Closer Look

Further details on each of the presses above are provided in alphabetical order by OEM name. Additional OEMs were contacted for this article and either did not reply or did not wish to release details in time for inclusion. We expect further announcements before and during drupa 2024.

To avoid redundancy, all presses below use water-based, CMYK, pigment inks and are capable of printing on offset coated stocks and auto-perfecting/duplex printing.

Canon ProStream 3000 (Available)

The ProStream series is Canon’s top-of-the-line continuous graphic arts press. The latest generation, the ProStream 3000, builds on the success of the ProStream 1000 and 1800 models first introduced in 2017 with features intended to improve performance and respond to customer feedback. The 22-in. press is available in two models offering speeds of 263 and 436 ft./min., respectively. The faster model uses a higher capacity hot air blower dryer and updated dryer configurations to process media as heavy as 200 gsm or 7-pt at full speed. The heaviest media supported has also been expanded to 300 gsm. At top speed the press will run at 1,200 x 720 dpi and slows by 40% to run at its top resolution of 1200 dpi.

A “Smart ColorGrip” feature optimizes the use of primer for different media which positively impacts quality as well as running cost. As presses get faster, downtime gets costly. Canon has included several features to maximize uptime including inline quality control with automated nozzle monitoring and compensation and the long-awaited automated splice handling. Canon estimates that this press has the potential for 30% greater uptime than previous models with an impressive monthly duty cycle of up to 62 million US letter pages. This press is commercially available and boasts several installations in the US and Europe.

Canon ProStream 3000 Xray

Canon varioPRINT iX 1700 (Announced)

On the sheetfed front, Canon has expanded their varioPRINT iX line of B3+ format presses with a new approach enabling a lower price and a smaller footprint than previous iX models. A vertically integrated press, the varioPRINT iX 1700 is the first production inkjet press to use Canon’s thermal printheads and comes with Canon’s PrismaSync DFE. With the new printheads comes a new water-based polymer ink containing highly saturated pigments and a supporting primer which Canon describes as a “conditioning liquid.”

The press, still in its “technology preview stage,” promises a new registration correction mechanism to simultaneously correct paper skew and horizontal misalignment to provide dependable image alignment at its top speed of 165 US letter IPM. An air feeding system supports reliable in-take of a wide variety of media, but full details of media compatibility have not yet been released. Commercial availability is slated for 2025.

Canon varioPRINT iX 1700 B3 Sheetfed Press

HP PageWide Advantage 2200 (Available)

The HP PageWide Advantage 2200 with HP Brilliant Ink, which became commercially available early in 2023, represents a major revamp of the PageWide line. The visual difference is striking with iconic PageWide arch reduced by half. Moving components outside of the arch enables drying capacity and greater configurability in a reduced footprint. It also isolates sources of heat and moisture from the printheads which should result in greater printhead life and reduced maintenance costs associated with thermal heads. The 22-in. press can be configured with up to three dryer zones and either active or passive cooling. Like other PageWide models, the press offers multiple speed and quality modes:

- Mono Performance: black only using single, or high, drop weights at up to 800 ft./min.

- Performance: CMYK using a single, high drop weight at up to 500 ft./min.

- Performance HDK: using dual drop weights (high density) on black ink and single drop weight on CMY inks at up to 500 ft./min.

- Quality: using dual drop weights for CMYK at up to 333 ft./min.

The Advantage 2200 runs 40 gsm to 300 gsm or 14-pt. media and uses HP Optimizer pretreatment fluid. HP has long supported splice detection for automated winding systems and the 2200 is no exception. The updated Digital Front End (DFE) supports the HP Color Vision System with HP Quality Image Check (QUICK) Vision System Color Calibration. With a duty cycle of up to 85 million mono images per month or 58 million color images per month, the Advantage 2200 is a graphic arts workhorse, but not the only one in HP’s stable. HP also made significant speed and performance upgrades to the PageWide T250 press which also serves the graphic arts segment.

HP PageWide Advantage 2200

KODAK PROSPER 7000 Turbo (Available)

The Prosper 7000 Turbo is the fastest of the graphic arts presses we are reporting on and arguably the fastest graphic arts press available even at the lowest of its three speed modes:

- Quality: 650 ft./min (200 m/min.) at 600 x 900 dpi

- Performance: 1000 ft./min (300 m/min.) at 600 x 600 dpi

- Turbo: 1345 ft./min (410 m/min.) at 600 x 450 dpi

I say “arguably” because, although the Kodak Stream continuous inkjet (CIJ) printheads and Kodak EKTACOLOR Inks deliver great quality at 600 x 900 dpi in Quality mode, this is not an apples-to-apples comparison with presses (including Kodak’s own) that deliver substantially higher native resolution. However, for printing companies where offset media compatibility and approaching offset productivity are most important, this 25.5 inch wide, 3-up press provides a robust option with an ultra-high duty cycle of up to 239 images per month. The 7000 Turbo supports media from 42 to 270 gsm and folding carton board up to 24-pt. Coated papers must run in Quality mode. It became commercially available in 2023 and Kodak announced their first sale in August.

KODAK PROSPER 7000 Turbo

KODAK PROSPER ULTRA 520 HD (Available)

The PROSPER ULTRA 520 HD uses Kodak’s latest ULTRASTREAM CIJ printhead technology offering a native resolution of 600 x 1800 (and fine 3.75 pl drop) with hardware-based Kodak screening technology to drive speed, performance, and image clarity. It is unique in delivering its full speed of 500 ft./min. on coated and uncoated stock at top quality. With a 20.5-in. web width, the 520 HD can produce 2,148 US letter images or 216 B2 “sheets” per minute. Productivity is enhanced with support for auto-splice unwinding systems.

There are two versions of the press both using intelligent near infrared (NIR) drying. The C520 for commercial markets has four dryers and supports media from 45–270 gsm. The P520 for publishing markets with dryers supports paper up to 160 gsm, although it may run heavier papers at reduced speed.

This vertically integrated press, announced in 2022, did not become commercially available until new KODACHROME inks and OPTIMAX primers were launched this year. The new ink employs a proprietary pigment micro-milling process, which creates extremely fine nanoparticle pigments. The press also uses the KODAK Intelligent Print System (IPS) to continuously monitor and optimize stitching, color-to-color and front-to-back registration and the KODAK 900 Print Manager DFE with ADOBE APPE 5 RIP. An optimized interface with KODAK PRINERGY Workflow maximizes production efficiency and data security. Kodak has announced the first sale of the press in August.

KODAK PROSPER ULTRA 520 HD

Kyocera TASKAlfa 55000c (Announced)

Kyocera’s expansion of its TASKAlfa line will bring its small footprint, low running costs, and entry-level price tag to a more demanding graphic arts customer. Critically, the 55000c supports coated papers where the 15000c did not. This is achieved, in part, with a new ink chemistry that does not rely on primer for media compatibility. Kyocera 1200 dpi printheads and edge smoothing technology are key to quality improvements. The Kyocera TASKAlfa 55000c is coming to market in Q2 2024.

Kyocera TASKAlfa 55000c B3 Sheetfed press

Ricoh Pro Z75 (Available)

While the Ricoh Pro Z75 Digital Press is not the first B2 sheetfed inkjet press, or even the first aqueous inkjet B2 press, it is the first aqueous B2 perfecting sheetfed inkjet press and that was a gaping hole in the inkjet market that has not been filled. Auto-duplexing a B2 sheet with the heavy coverage needed for graphic arts using water-based ink is not easy. Wetting and drying can damage the paper surface and impact registration. Ricoh slow-rolled the launch with a beta cycle that began in mid-2022 and it became fully available last month, and Ricoh has already announced sales in France, the Netherlands and UK in addition to the U.S. beta site.

The press uses Ricoh Gen 5 printheads (2 bits/drop) and proprietary inks and electronics. The Fiery N-500 DFE is a Ricoh/Fiery collaboration.

The Pro Z75 uses adapted Ricoh Gen 5 heads housed in a water-cooled environment, runs Ricoh water-based inks and the delivery system and electronics are also Ricoh technology—the DFE has been jointly developed with Fiery. Speed/media specs vary:

- Runs media up to 310 gsm/14-pt. at 4,500 SPH simplex or 2,250 SPH duplex.

- Runs 310+ to 400 gsm/24-pt. media at 3,000 SPH simplex or 1,500 SPH duplex.

- Support for boards up to 600 microns thick enables packaging (no speed reported)

- Will support media weights as low as down to 60 gsm uncoated and 80 gsm coated (by drupa).

Productivity is further enhanced with a two-drawer, multi-sheet feeder and the option to connect up to four drawers. The maximum duty cycle is 1.7 million B2 sheets per month. It’s also notable that, while launched as a CMYK press, it was engineered with space for two additional colors. It can also be configured with an optional pre-coater intended for uncoated sheets.

RICOH Pro Z75 B2 (Perfecting) Sheetfed Press

You can find further details about these presses, as well as coverage of the RICOH Pro VC80000 which was announced after the deadline for this article in the replay of our December 7 webinar “Production Inkjet from Customer Communications to Graphic Arts.” You can also drill into devices and compare specifications using the Inkjet Insight Device Finder.