The varied world of printing, and more generally making things with inkjet, has been the focus of many of my tech-focused posts over the last two-three years, including tiles, décor, packaging, labels, and the rest. I previously wrote a short article on the importance of collaboration in the development of inkjet which mentioned how equipment makers (OEMs) have to get so many contributing technologies to converge. I’m kicking off a new “Integration” series that provides a step-by-step look at the combination of equipment, components and software that go into development of printer solutions.

Key Parts of the Puzzle

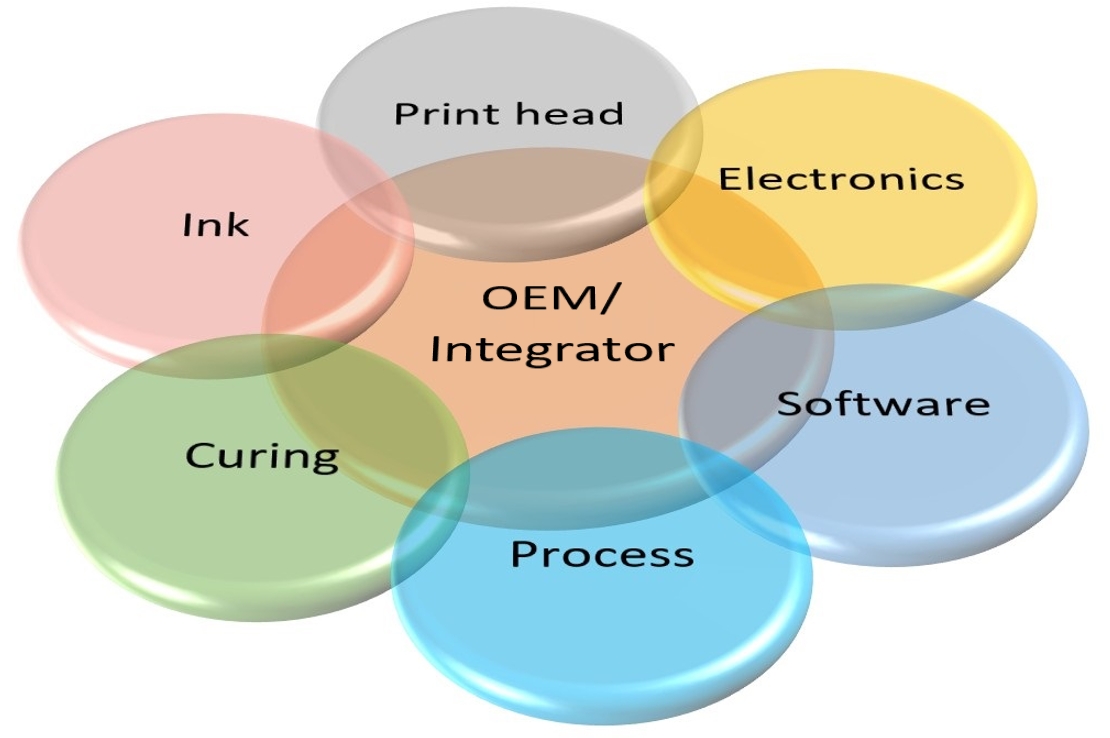

Whether the purpose of the development is a full standalone printer, or if it is intended to be combined with another platform as a retrofit, the key technologies required are the much same. Pat McrGrew provided a neat review of typical considerations previously on Inkjet Insight.

The most often cited interdependence is that between the ink, head and substrate, which are indeed intimately linked to the output print quality. In the production printing applications that have been the primary topic for Inkjet Insight since inception, this basic trilogy often holds. However, the print systems of today are may address a broader range of applications and quality thus requiring sophisticated combinations of mechanical design and software engineering tuned to keep the production running with the print quality made possible by those chosen combinations of ink/head/substrate.

Fig1: Technologies required for an inkjet development project.

The industrial inkjet market has benefitted from the development of hardware technologies implemented for production printers, including increased head addressability (dpi), multi-drop greyscale and nozzle compensation, as well as chemistry solutions like primers. Many of these developments are enabled by a continued developments in software, including getting all that data into those shiny, fast printheads.

Ink First

Unlike some approaches in graphics, where print platforms can be modified with relatively minimal engineering effort to accommodate different types of ink or substrate, truly bespoke industrial applications are based entirely around the ink formulation itself and its ability to meet the end use application requirements. The system is then engineered to deliver the required fluid to the target substrate geometry. That’s why we spend a lot of time in the DoDxAct lab prototyping with different commercial inks to explore the suitability of existing material to meet new requirements.

Ceramic tiles, discussed previously, is a great example of an ink-led process. The firing of the glass requires a very specific chemistry of the colorants to react during firing and the dense inorganic materials place specific demands on the design of the printer to achieve a robust and reliable ink jetting over time. This includes both printheads (including recirculation) and the design of the inks delivery system, often abbreviated to IDS. The final piece in the ceramic jigsaw is the ability to scale the printhead arrays and to extend image lengths to increase the possibilities in form factors beyond those previously possible with roller printing and screen printing.

The “ink first” approach has worked for a wide variety of industrial projects as diverse as automotive, textiles, photovoltaics and 3D printing in addition to numerous types of consumer products textile decoration, like footwear.

Fig 2: Some industrial manufacturing applications, like photovoltaics require very specific material properties.

A Bit More on Printheads

The choice in printhead technology has continued to grow in terms of number of suppliers and products, both thermal and piezo as well as the different types of technology being developed for emerging & future potential applications. Mary Schilling and I covered some of the mainstream options in our previous webinars in February/ October 2021 and went into even more detail in the more recent feature on silicon-based heads.

The choice of a given head is a combination of:

- Productivity: droplet size & frequency for enabling desired speed of print

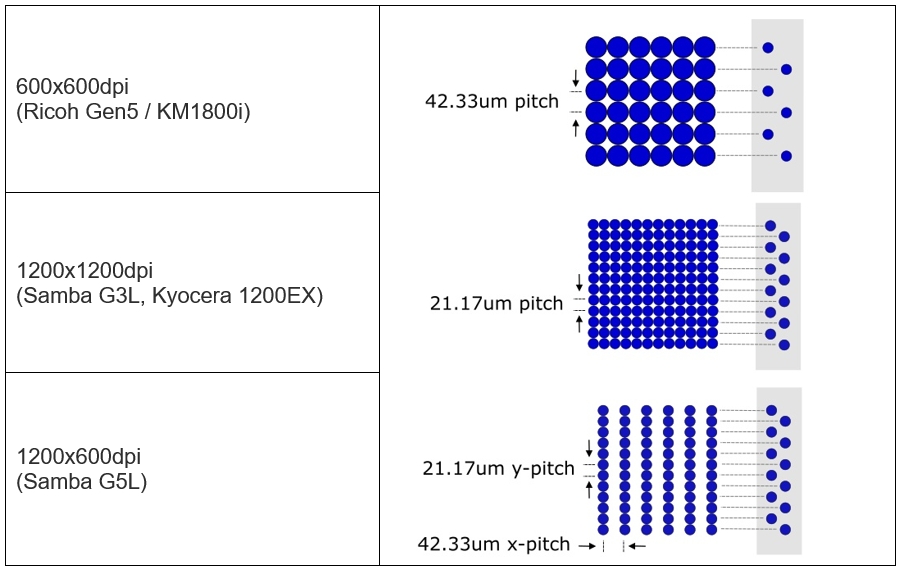

- Addressability: the native ability to put down drops with a certain dpi

- Ink compatibility / recirculation: whether or not the target chemistry could break the head

- Form factor: head size, form factor for making a print module

The first two are intrinsically linked since addressability of the target process in the print direction will be limited by the combination of the desired speed (feet/sec) and maximum head frequency (drops/sec). Since printing faster and faster is the target of many production inkjet developments these two factors are usually put first.

Fig3: Addressability of the pixel raster with different heads can be asymmetric.

However, the speed reduces to a somewhat a moot point if the ink exposure causes the faceplate to fall off – an extreme example, yes, but it has happened!! Also moot if the functional particles can settle in the nozzles, resulting in the head becoming more of a consumable than expected. Recent market introductions, like those from Xaar and others will be reviewed in a future post in this series.

The final consideration is the reason why specific printheads have proven popular for printers like those for hollow shape printing, since it easier to predict drop landing accuracy from more closely spaced rows. Piezo printheads like the Dimatix Samba™ and Epson D3000 offer innovative geometries to overcome typical head stitching issues, whilst thermal printhead modules like those of Memjet can deliver incredibly compact CMYK solutions which offer almost plug-and-play useability, although potentially with a little less ink flexibility.

Getting off the Ground

Testing the feasibility of a new application is an important first step before investing significant funds into building something new. As we have mentioned, testing the chemistry is one of the most important steps. This is something that we help with regularly at DoDxAct by taking unique formulations and finding a way to deposit them onto the required surfaces to enable end-use testing and show fitness-for-purpose.

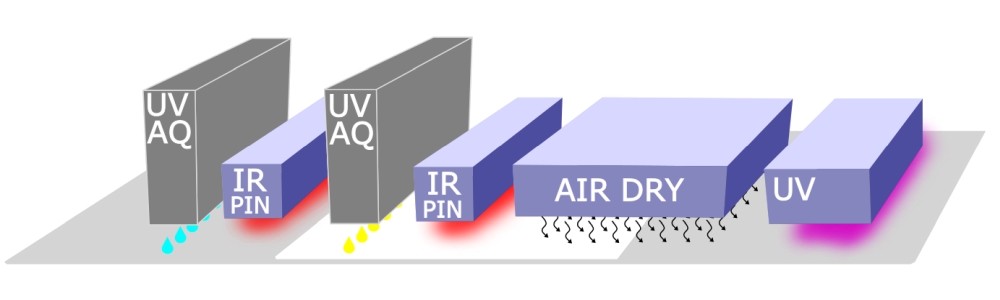

The other big piece of the feasibility jigsaw to establish, prior to designing the printer, is the process itself. This is essentially the “how and when” for deposition and dying/curing based on the number of materials and how they interact with the substrate and each other. The chemistry dictates what kind of drying will convert the ink to the functional part (UV, IR, direct/indirect heating) but the process is the combination of energy input with time versus the amount of fluid being ejected. Fig 4 is a 2D schematic taken from our previous article on Hybrid inks but multi-material 3D printing applications, such as additively manufactured electronics (AME), are an even better example of just how complex it can be to optimize a process to meet several objective simultaneously.

Assuming all goes well to this point, then a printer development/design project is usually the logical next step. The ink/head testing remains an important part of informing key decisions like printhead selection, especially when it comes to compatibility. Here you can find support directly from the head manufacturers themselves or from independent firms, including specialist integrators who can help move you project forward based on their hard-earned years of experience and well-developed resources. We will be mentioning some in our upcoming custom inkjet webinar in April.

Many of those integrators rely themselves on the other suppliers in the inkjet ecosystem and this is where the speed to development can be accelerated hugely by “off-the-shelf” hardware and software components that can be adapted to different heads, mechanics/geometries and process workflows.

We shall be exploring most of these topics in the rest of the series, but we can only really scratch the surface in an article. If you want to get a head start on your understanding of inkjet technology, the renowned Ink Jet Academy (IJA) will next be presented face-to-face on May 16-17th in Florida at the IMI Inkjet Conference event It is presented by Mark Bale, your humble Insight author, and covers many of the topics we just introduced but with way more examples over multiple days!