The Software Side of Inkjet

There are many categories of software products that can truly be considered “essential software” for production inkjet optimization. These are the tools such as production planning, output management and color management that help an organization to drive manual processes out of production workflows.

Unfortunately, for small firms justifying a $350K device as well as a larger firm justifying a $3 million+ device, companies often skimp on building the costs for essential software into the mix. This can be a critical and costly mistake.

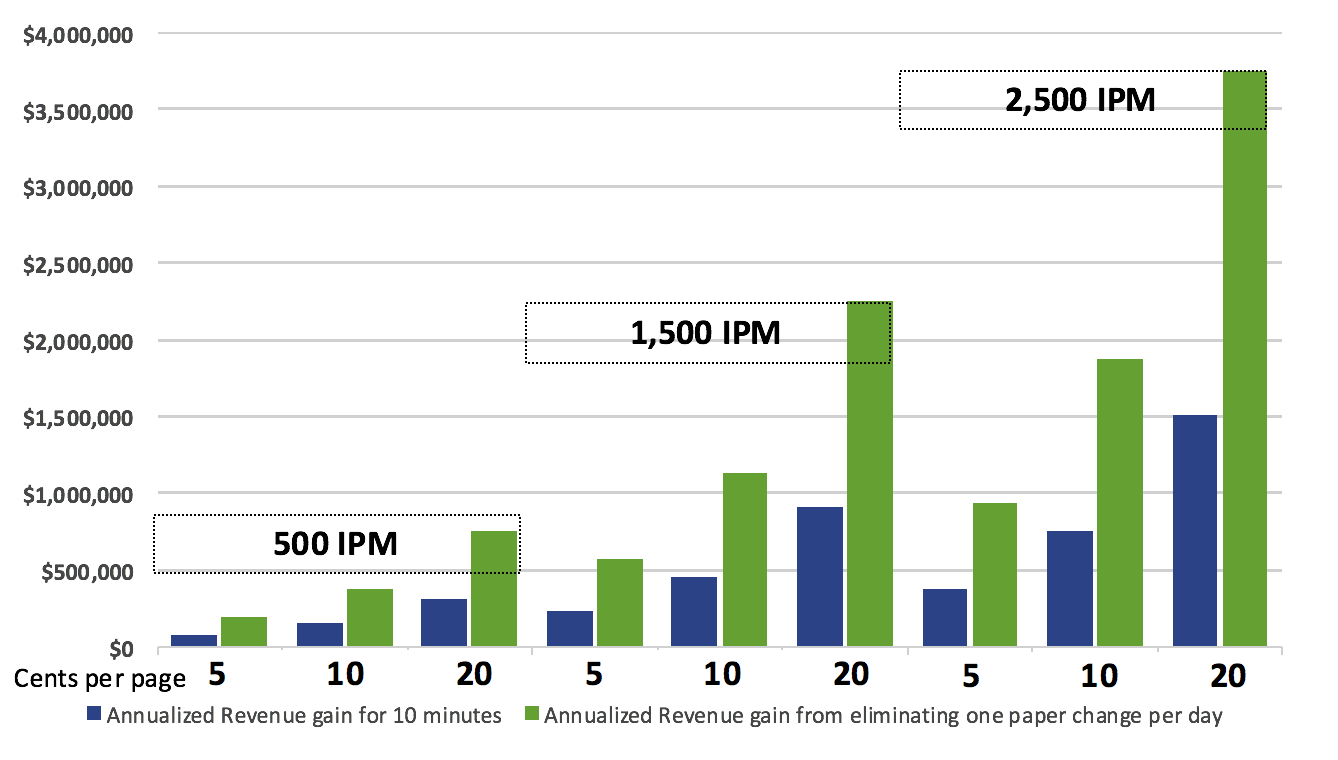

As faster and more productive inkjet devices reach the market, maximizing productive uptime is truly essential. In fact, we generally recommend that companies invest in software and workflow design before buying a new press to ensure that they don’t waste a minute once that new machine hits the shop floor. Consider the case of a continuous feed device producing 2500 letter sized pages per minute. There are devices of this speed or faster from Canon, HP, Ricoh and Xerox currently on the market. If running the press 6 days per week and 50 weeks per year at an average price of 5 cents per page, each minute of workflow improvement adds $37,500 in revenue per year.

Not impressed yet? What if your production planning and output management improvements enable you to avoid just one paper change per shift under the same scenario? At an average of 25 minutes per paper change on a continuous device, this would result in nearly $1 million ($937,500) in additional revenue per year. Now what if you have two devices? Or three? Do I have your attention, yet? I realize that you may not run the press at full speed all the time – particularly if you are creating very high quality output. On the other hand, that high quality job may be worth more than 5 cents per page.

Consider that inkjet is rapidly moving into more high-color and high-value application segments such as commercial marketing collateral, color books, high-end personalized direct mail and even photo books where a higher price per page is warranted. In these markets the revenue return per minute of workflow improvement is also higher. An annualized revenue gain for 10 minutes of workflow improvement per day at a price of 20 cents per page is $1.5 million. Even if you were running the press at half speed you’re still looking at $750k. That will justify a lot of software. And where might you get a 10-minute improvement in your workflow? Perhaps you can’t completely eliminate a paper change from your daily routine, but you can use automated color management processes and production planning to plan the order in which you load papers to reduce the time for tuning during each paper change. Every paper change should be treated like a NASCAR pit-stop because every second counts. Just a second added to productive time on every shift could be worth anywhere from $100 to $2,500 over the course of year. (Maybe you should make the business case for a stopwatch.)

The chart below shows examples of annualized revenue gains from a 10-minute efficiency gain per day and for eliminating one paper change per day on presses delivering 500, 1500 and 2500 letter images per minute at prices of 5, 10 and 20 cents per page.

Assumes 6 day week, 50 weeks per year at maximum device speed. See dealer for details – your mileage may vary.

When you’re building your business case for investment in an inkjet device, you can use this type of analysis to justify the additional investment in software needed to optimize workflows. Even on a slower, sheet-feed press, a 10-minute efficiency improvement could pay for your additional software costs in the first year. In high-value application segments the justification could be even faster.

Good Workflow is Designed – Not Bought

Keep in mind that an efficient workflow does not come along with the software you buy. Good workflow processes are designed, not bought off-the-shelf. Two companies may have the same devices and software, but their workflows may be completely different – even when pursuing the same types of customers. Guess what? The one with the better workflow and the flexibility to support their customer’s workflows, will be significantly more competitive. Jennifer Matt’s video post called “Sell Workflows Not Print” talks about workflow from the customer perspective and why your customers are really buying workflows – definitely worth a listen.

Which leads me to a point that I will pursue further in a future post: all the efficiency in the world won’t matter if you don’t have the volume of business to keep your press busy. There is also essential software at the front and back of the production process that makes it easier for customers to do business with you – and for you to accept business from your customers.

If you already own a high-speed press and haven’t optimized your workflow, you are missing out. In the best case, you’re not getting revenue through the door as fast as you could. More likely, you are missing out on some business because you can’t price as competitively as a competitor with a better workflow (not that I’m advocating competing on price alone). For most operations, the ability to logically organize jobs and group them together for production is the key to keeping the printer up and running, avoiding paper waste and maximizing profit. Is it time for you to make the business case for essential software?

Please also see my previous post on gathering software requirements for developing efficient workflows which includes a handy spreadsheet tool for download. If your business case for software also justifies a budget for some helping hands to design your workflow, please keep Inkjet Insight in mind. After all, we’ve been right helpful so far, right?

Have other great examples for justifying software purchases? Leave a comment or get in touch.

Elizabeth