Previously, I talked about a cool project using METIS 3D scanning technology for reproducing organic textures for inkjet décor applications. Although this project was for an in-plant manufacturer, business opportunities are available for various print service and product manufacturers which need accurate print reproduction.

Texture scanning spans across varying print markets. Opportunities to enhance the reproduction of fine art on wide format devices to texturizing signage and displays with varying varnish levels for flat beds relief printing. For commercial, captured textures for post coatings and embellishments offer unique patterns which you can offer customers.

In talking with Rob Lawrence, Business Development Manager for Metis scanners at CGS –ORIS, we discussed opportunities for designers and printers to capture realistic surface data and how it could expand creative applications for all print markets. We both agreed, access to such technology could create an abundance of creative uses for both printers and manufacturers.

METIS scanning technology provides opportunities for graphic arts firms and print service providers. “With advancements in 3D and 3D-like technologies, there is a need for realistic surface data, and the METIS’s ability to capture and deliver graphics of the surface attributes of color, texture, and glossiness will mean greater realism with these technologies,” says Lawrence.

Details are in the Capture

The METIS technology scans materials from a topical level, this approach also benefits colorimetry creation for materials which would be impossible to profile by traditional methods. When accurately reproducing hard to replicate detail, proper color management is just important as the images color data. METIS has partnered with ColorGate Digital Output Solutions, GmbH to prepare colorimetry for accurate color management which traditionally took hours now takes just minutes.

Benefits Beyond Print

I asked Lawrence if this technology could also bring additional revenue sources to graphic arts firms?

Multi-use METIS Surf 3D ColorGate Edition creates textured scans and colorimetry.

“Being able to reproduce 3D texture reproductions with existing UV printing equipment or providing scanning services for CGI/PBR (computer-generated imagery/physical based rendering) applications.”

“It could also expand offerings for print service providers’ clients in that they can provide their clients with extremely color accurate photorealistic and/or tactile realistic reproductions, and the scanners can deliver image data in whatever format is needed for a given print manufacturing method. And scanning surfaces are required for a host of needs beyond print such as virtual/augmented reality, CGI, and PBR. Computer-generated room scenes, product displays, video game environments, and movies are increasingly calling for more photorealistic surface textures” Lawrence adds.

Think Outside the Box—and Then Scan the Box and Everything Inside

What advice would Lawrence give creative designers when thinking about doing custom scanning for their production process?

“First of all, think outside the box,” he says, “but remember that the scanner’s job is to give you an absolutely faithful capture of the original. So, before you send a surface to be scanned, be sure it is as close as possible to how you wish the final output to appear. This includes gloss/sheen levels. But don’t just get stuck on one option, the METIS software enables real-time lighting perspective changes post-scan to allow for virtually unlimited perspectives that would take other scanning technologies days to try to create. is easy adjustable to scan multiple scan mapping options in less time than other devices.

The METIS’s ability to develop colorimetry, isolate and capture these element detail and depth will mean you will have less post-scan editing and the right maps to deliver to the different manufacturing processes.”

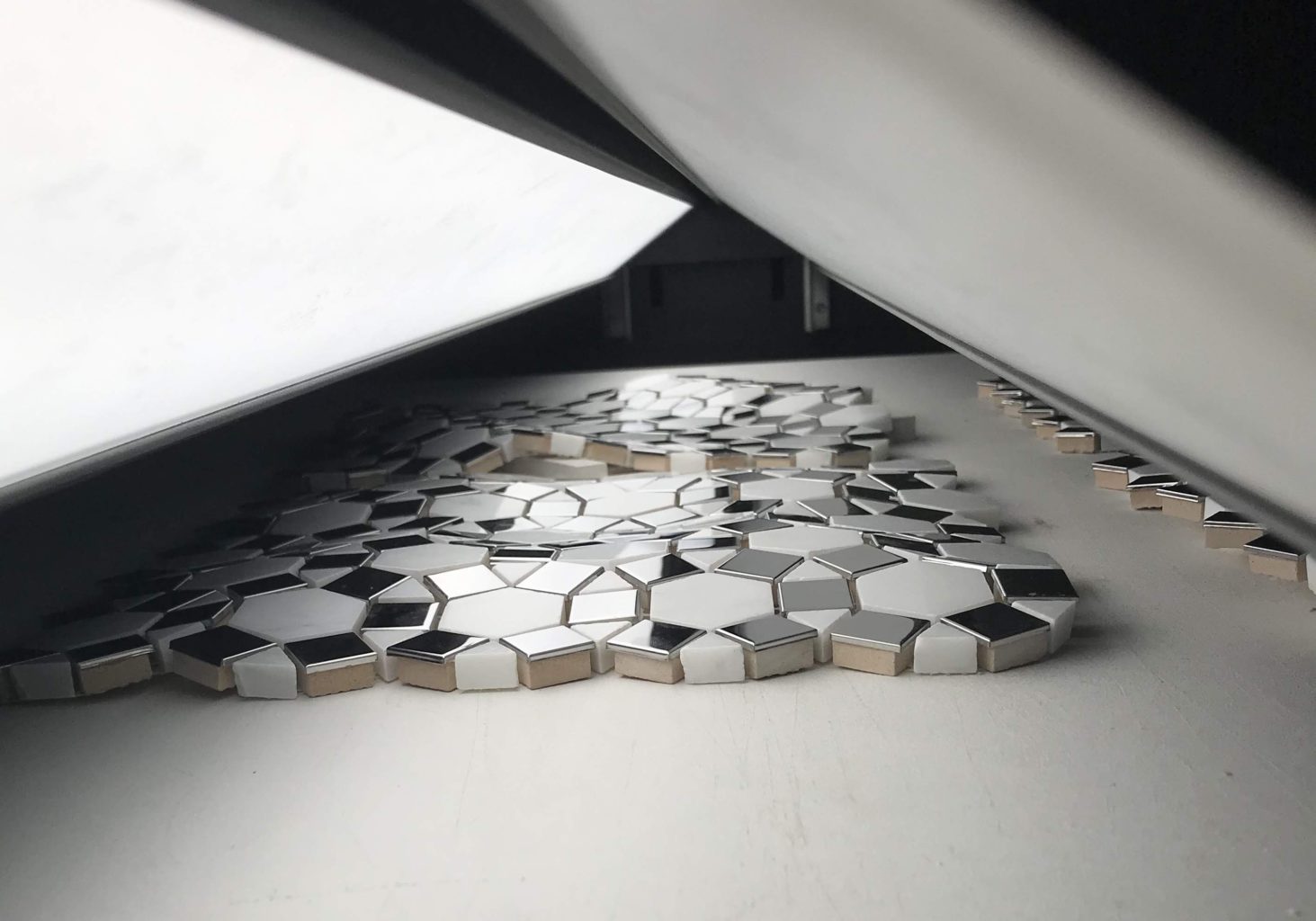

Designers don’t limit yourself to just what you have available. Flat pictures and patterns which can be found through stock photo or traditional flatbed scanners won’t give the topical and depth data needed if designing a piece which requires a realistic effect. Organic items such a leaves, wood, concrete and marble have a natural depth and detail which must be captured accurately for replicating with UV inkjet. Manmade items such as premade ceramic or glass tile sections can also be scanned to make continuous image for wall décor only if all the light source data is included.

Ceramic, metallic and glass tile scanned for RGB and multiple light reflection data

This extra data will allow the depth of the UV gloss printed to vary making the printed piece extremely realistic.

If you are lucky enough to have a project requiring a METIS scanner, it is a unique technology that can really provide some serious differentiation with benefits that extend into all print markets which you may be in.

So, designers don’t just visualize; but customize. Develop custom patterns and effects using technology which gives you many options for texture and lighting options. Life is not flat, so why design that way.

More information can be found at CGS ORIS (www.cgsusa.com) and at METIS-Group, Italy (www.metis-group..com)