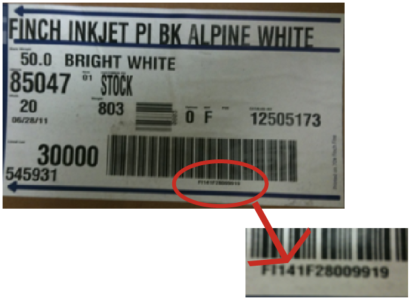

TAPPI is the technical arm of the American Pulp and Paper Association. They are an ANSI-Certified Standards development organization, and one of the standards that they have developed is the roll label that mills use to identify and track manufactured stocks.

This label identifies each roll using a numbering system, or TAPPI Roll Identifier to assure that all US paper mills use a common language. A TAPPI Roll identifier is as unique as a social security number; no 2 rolls should ever have the same identifier assigned.

This identifier is especially important to the printer when reporting any damage or paper defects such as side to side shade differences, baggy rolls, crushed cores or excessive web breaks to the mill. It is also important to the mills in determining the root cause of problems reported by customers. Here’s why…

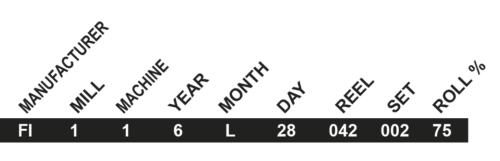

The TAPPI roll identifier encodes the following information:

Paper Manufacturer

Production Mill (Note some mills have multiple manufacturing plants. and some roll identifiers may contain a combined number representing the manufacturer name and mill if the mill has only one plant and paper machine.

Machine ID: Paper machine the roll was manufactured on

Year manufactured

Month manufactured, encoded as a single letter:

A = January, B = February, C = March, D = April, E = May, F = June, G = July, H = August, J = September, K = October, L = November and M = December

Day manufactured: 2 digits

Reel # it was produced from that day: 3 digits

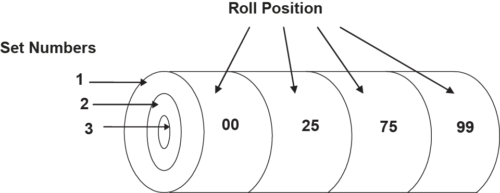

Set Number: Where within the roll the paper was produced

Roll %: The last 2 digits indicate the percentage of the distance from the front edge of the reel where a particular roll starts. With the exception of a back roll, which is always 99. These percentage numbers can vary by the number of rolls which are produced from the length of the reel.

You can understand how important this information will be in tracking down the cause of manufacturing defects, so make sure you log the TAPPI roll ID and keep it with the job ticket during production. It’s a good way to track paper quality and print consistency. Especially if you conduct any print quality analysis or color quality tracking.