Domino Printing Sciences delivered a very well-orchestrated virtual launch event today for their new, generation 7 digital label press dubbed the N730i. The new press is the first major inkjet endeavor bringing together the technology assets of Domino and parent Brother Industries since their acquisition in 2015.

Philip Easton, Director of the Domino Digital Printing Solutions division commented “This is the most significant new product we have launched since we started in the digital label press business. It has been a huge collaborative team effort, spread over five years, involving our colleagues at Brother Industries, supplier partners, our development team and our existing customers. Today, we are so proud of what the N730i delivers, as we truly believe it is setting new standards in high-performance inkjet label Printing.”

Overview

Asked for three words to describe the new press, Julie Cross, Technical Director, Digital Printing with Domino said, “Only three? Consistency, quality, speed.” These are apt descriptions of the improvements that Domino has brought forward beyond the previous generation of technology, but other attributes might include flexibility, accessibility and extendibility.

Domino executives emphasized that both the print quality and the consistency have been significantly enhanced. Print resolution on the N730i is 1200 dpi versus 600 dpi for the N610i. This is accomplished using a combination of the new Brother BITSTARTM high resolution piezo print head and the Domino in-house developed and manufactured UV90 ink set. A few of the key features of the new press are:

- Colors: up to 7 colors including orange, violet and white delivering up to 92 percent of Pantone range

- Coverage: Double bar white enables up to 76 percent opacity

- Resolution: True 1200 by 1200 dpi

- Speed: 70 meters per minute including double white

- Dot size: precise, multi-drop control of 2.1, 2.8, and 3.3 picoliter drops for 4 gray levels

- Width: Up to 1 meter (39 inch) roll size. Prints minimum of 170 mm to max of 340 mm

- Media: prints on all flexo compatible stocks without primer plus additional media with floodcoat primer

- Configurability: option to add up to 2 flexo stations in-line

- Durability: Solid industrial frame

There are a host of automation features including automated roll lifts front and back, a splice detection system, automatic density management and print head alignment, configurable graphical user interface including JDF/JMF data transfer for automated job set-up and detailed reporting.

This is a vertically integrated solution with all of the presses designed and manufactured in house for complete quality control.

Brother BITSTAR Piezo Print Heads

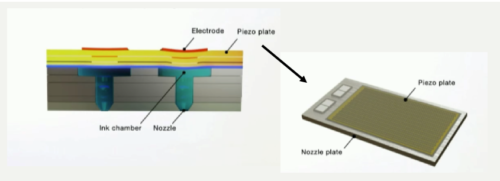

Kan Ishikawa of Brother Industries hailed the BITSTAR Print head as the result of 30 years and 50,000 hours of R&D investment. It is built around a patented, triple-layer polycrystalline micro-piezo technology that delivers precise nozzle control for optimum drop placement accuracy. The drops themselves are on par with the smallest in the industry with the smallest at 2.1 picoliters and additional nominal drop sizes of 2.8 and 3.3 picoliters. Small, finely controlled drops are keys to delivering sharp images, smooth gradients, fine text and in controlling ink density across images. The company also touts seamless stitching between heads. When asked if the system included nozzle compensation to prevent artifacts (jet-outs) the Philip Easton, Director of the Domino Digital Printing Solutions responded that they didn’t believe that they needed it as the heads are extremely reliable noting that drop placement accuracy has been tested with over 200 billion firings and have seen very little difference in drop size or velocity. “Nozzle compensation is a sticky plaster over a problem,” said Easton, “Better solution is not to have the problem. “ Only time, and customers, will tell if their confidence is justified.

BITSTAR triple-layer polycrystalline micro-piezo technology

Domino UV90 Ink

Domino’s generation 6 technology demonstrated the performance of their in-house developed UV90 ink set. They have achieved a maximum Blue Wool Scale of 8 on specific substrates demonstrating superior fade resistance. It has also demonstrated excellent abrasion and scratch resistance. The UV90 white ink delivers opacity of up to 76% enabling use a replacement for silk-screen processes. Coverage and opacity also enables labels designs to include haptic, tactile, three-dimensional effects without the need for a post process. Domino notes that UV curable inks have a less distinct environmental footprint than alternative solvent inks, with an average across the ink range of 3.3% volatile solvents. Based on industry standard cross hatch and tape tests, Domino UV90 inks maintain full adhesion on a wide range of substrates without pre-coat or varnish, however additional fluid options are available.

Flexo Flexibility plus Accessibility

In addition to configuring the number of ink colors on the device, customers can also select one or two optional flexo stations. Installing a flood-coat priming station before the inkjet process further expands the range of media available. A second station, following the inkjet process is available to to support varnishing, add a brand specific spot color or to enable more cost-effective flood white for shrink sleeve applications

Domino highlights the print carriage design which uses an innovative slide system. When opened, the operator can allowing pull the print carriage outside and forward the front of the machine. The servo-based frame includes automated roll lifts for both unwind and rewind.

i-Tech “intelligent Technology” features

Domino also announced two new features designed to improve the efficiency, usability, and reliability of the N730i The first, i-Tech SetAlign is an automated system that sets density and accurately aligns the print heads for more uniform and seamless print quality across the full web width. The second, i-Tech CleanCap2, an automated print head cleaning and capping system which reduces ink wastage and manual operator intervention. Previous i-Tech features such as i-Tech ActiFlow, UltraMix, and WebRev also continue to be available on the new model.

“Push Button” Ease of Use

N730i has a completely new graphical user interface called Domino SunLight. While not demonstrated in detail during the launch, it is described as “completely intuitive and highly configurable.” An enhanced version of the ESKO Digital Front End underpins the controls, providing management of CMYKOVW, for lower ink usage and an increased gamut. The system also supports the JDF/JMF data transfer format allows for automated job set-up, workflow integration and reporting.

The Path Forward

Domino emphasized that the N730i is a path forward and they expect to deliver additional products on this platform. However, they have no plans to discontinue their N610 technology. Domino has close to 1,000 installations of this technology and believes that there is a market for both devices. The N610i is available in both a roll and a hybrid configuration. While hedging during the launch on future plans, based on the popularity of the generation 6 hybrid device, I would be surprised if we did not see a hybrid version of the generation 7 technology in the near future.

The first customer for the N730i, Adrian Brown, Managing Director of Olympus Print Group was on hand for the launch. Olympus has both the N610i roll and the hybrid press and was very happy to add the N730i to the portfolio rather than replacing. “The bar never falls, it always rises in this market.” Said Brown. And where the customers go, Domino goes with them.

You can view full specs of the N730i on our Device Finder.

For more on the label market, see also Inkjet Labels Come of of Age by Mark Bale.