Inkjet printing has been around for a long time. Yet, we are still talking about innovation. Why? We continue to see innovation in inkjet inks because there are still market unmet needs to fulfill and there are still new and emerging markets to serve. Read on to learn more about some of these unmet needs and how innovations in inkjet inks are rising to the occasion – or not.

What challenges must inkjet innovations address?

To answer this question, I called my long-time friend and digital inkjet printing expert, Gianluigi Rankin. “Without a doubt, the market needs inks that print on all the coated substrates,” Rankin told me. When inkjet inks were developed, they were designed to go through printheads and to deal with the mechanical variations of different printers. Every substrate to be printed upon has to go through a print test. Some substrates work, but many do not. So why not just pick a different substrate? “That’s the problem,” Rankin informed me. “Inkjet inks do not perform on all the substrates that were created for high volume printing applications such as offset printing,” he continued. “Rather, the substrate has to be optimized for the ink.

In theory, optimizing the substrate for compatibility with the ink (and printhead) sounds good. When each part of the system is optimized, the system should work beautifully, and it does. However, economies of scale come in to play. It turns out that paper mills do not get excited about creating new products that only generate 20 or 40 tonnes of substrate. “It really becomes a game of chicken or the egg,” Rankin explains. “What must come first, the substrate or the ink? Everyone expected substrates to come along much faster than they have. This creates an opportunity for inks to be specially designed for both the accepted and widely available substrates in a given application as well as any other special requirements for that application,” states Rankin.

Why the substrate challenge exists

Liz Logue, Vice President of Inkjet Strategy for EFI explains why analog-compatible substrates do not all work with inkjet inks. “The chemistry of inkjet inks and analog inks are very distinct. Particle sizes are very different between analog inks and inkjet inks. The percent solids is also very different, which affects the viscosity.” Imagine a paste for analog inks and think of inkjet inks as more of a liquid. “You need a smooth surface so inkjet inks can sit on top. This is most often achieved with the use of a primer to achieve ink performance.”

Innovating the inkjet process to address the substrate challenge

While most inkjet applications continue to struggle with expanding the number of printable substrates to match analog printing, the garment decoration space is addressing the substrate challenge by modifying the print process itself.

A number of printing methods have emerged to enable garment decoration on different substrates. Dye sublimation works well on light colors of polyester. Dye sublimation does not work on dark colors or on cotton blends. Pigment inkjet inks were developed to broaden substrate selection in garment decoration as they work very well on cottons and many cotton blends. Pigment inks require a chemical pretreatment to go down on many substrates to optimize the color. Unfortunately, the pretreatments can make the fabric stiffer and, in the case of dark colors of polyester, the pretreatments interact with the fabric dyes creating an unwanted halo effect. Garment decorators want to broaden both the colors and fabrics they can decorate as consumers have pent up demand for additional variety.

Last year, Inkjet Insight covered the launch of KODACOLOR Ink Technology, an ink innovation from The Eastman Kodak Company that promised to revolutionize the garment decoration space by enabling Film-to-Fabric (FTF) printing. Others may refer to this technology as Direct-to-Film (DTF printing). I called Grant French, Business Development Manager for Kodak to see how the technology has progressed since its launch in early 2022.

French told me KODACOLOR Technology is doing very well due to its ability to increase the range of substrates a garment decorator can print. “It has increased the number of printable substrates by a massive percentage – I’d estimate as much as an 80% increase,” says French. “In prior systems, garment decorators were limited to a subsegment of certain cottons that could be successfully printed on. Garment decorators could print on cotton and cotton blends up to 30 percent to maybe 50 percent. Go above 50 percent cotton and too much color would be lost. If the garment decorator wanted to print on dark colors, they had to screen a block of white color to be able to print.” This negatively affected fabric feel and increased the cost to print. “Now with FTF printing, garment decorators can do nearly all cottons, polyesters, felts, wools, etc.,” exclaims French. “Sales have flipped to where we sell more FTF than we do DTG ink. FTF has truly opened up new markets around the world.”

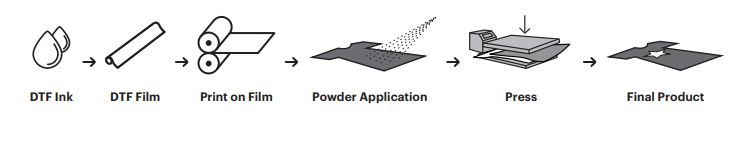

The FTF system allows custom designs to be printed on special films combining the benefits of digital inkjet and transfer printing. FTF ink systems can be used with most modified inkjet printers and involve three simple components: powder, film, and ink.

French describes a simplified process where colored ink is printed first on a special film and is followed by a white ink layer. A special powder is then applied to the back of the white ink layer. A decorator flips the film over and places it on the piece to be decorated, then presses it for about 15 seconds on a heat press at a low temperature cure. Done! No pretreatments. No steaming and washing. Reduced discoloration and energy usage as a result of the lower cure temps and times versus other printing methods.

The DTF process. Image courtesy of The Eastman Kodak Company.

In addition to broadening substrate selection, Kodak’s innovations in the KODACOLOR Ink System also make printers easier to manage for the garment decorator. The specialized KODACOLOR Technology formulation reduces head clogs while requiring less user intervention overall versus other inkjet systems. French states, “garment decorators are enjoying an increase in up time. As a result, they are printing more shirts and other items while making more money with happy customers. The FTF system makes it easy to print whether Grandma decides she wants to print for her local club or if a major brand is delivering premium athletic wear.”

Example of a Girl Scouts™ t-shirt printed with the KODACOLOR Technology FTF system. Photo courtesy of Coldesi, a provider of printers and consumables for the garment decoration industry.

What’s next in inkjet ink innovation?

French cautions all innovators to continue focusing on continuous improvement. “You must stay close to your customers to understand what is and what is not working. You have to consider unmet needs and continue to address those unmet needs – both to enable your current customers’ growth and their long-term business sustainability.” Rankin concurs, “Listen to your customers. They’ll direct you to the substrates they most want to be able to inkjet print on. Then you can prioritize testing for further ink innovation.”

I asked Logue what ink innovations she’s excited about. She lit up and said, “inkjet for corrugated.” The ability for single-pass machines to apply primer in-line has significantly improved substrate printability. While it doesn’t necessarily make all existing coated papers ready for inkjet, in-line priming is a big step toward expanding printable substrate availability. With in-line priming in place, Logue noted that inkjet innovations in corrugated focus around improving the print process – both from an operations stand point and a quality of working environment. Inkjet inks offer low smell making the work environment more pleasing. As sustainability has increased in importance, inkjet inks have been formulated to enable the recyclability of printed boxes. The ability to apply ink only where it is needed has also increased flexibility for the folding and gluing processes critical to box functionality.

EFI Nozomi single-pass inkjet printer. Photo courtesy of EFI

What Do You Think?

Do these new innovations in ink address the need to expand the amount of substrates that can be successfully printed on? Are there other pressing unmet needs that are holding back greater adoption of inkjet printing? Is one inkjet market more exciting than another? As market needs continue to evolve, we want to hear from you. What printing challenges are you facing? What challenges are the innovators in equipment, software and consumables facing to address unmet needs?