In a recent article on energy curable inkjet inks, we spoke about UV inks and some of their limitations. In industrial inkjet, water-based inkjet is undergoing a renaissance. When it comes to the most demanding applications, it is a challenge for aqueous inks to reach the required resistance properties without posing a longer term risk to blocking the head. This is where hybrids inks offer a potential solution.

What do we mean by hybrid?

We use the term “hybrid” when the ink is not easily classified by the traditional “platform” categories of UV, oil, water-based or hotmelt, most often when the formulator has intentionally combined two of these technologies. The aim is to combine the advantages of each approach to solve a particular problem. Consider the Centaur of Greek Mythology, which combines the speed of a horse with the fighting instincts of a human in a single being as opposed to a cavalry soldier.

We use the term “hybrid” when the ink is not easily classified by the traditional “platform” categories of UV, oil, water-based or hotmelt, most often when the formulator has intentionally combined two of these technologies. The aim is to combine the advantages of each approach to solve a particular problem. Consider the Centaur of Greek Mythology, which combines the speed of a horse with the fighting instincts of a human in a single being as opposed to a cavalry soldier.

The printing equivalent of the metaphorical horse and rider is the need to apply two technologies to solve one problem, such as a flexo-UV varnish to overcoat a water-based inkjet ink for label printing. In some cases this can perhaps represent the best way to do things, especially where the printer design allows, but combining function of the two fluids into a single product is beneficial when a single layer is needed.

Water-based UV

Probably the most common hybrid approach is the water-based UV ink, or AQ-UV for short. Although not new in concept, having been disclosed in patents since the early 2000s, AQ-UV inks have been subject of quite intense research over the last 10 years. This was likely motivated by a large number of print heads broken by early prototype inks containing conventional self-crosslinking resins. Today, there are many patents from the likes Konica Minolta, Sun Chemical, Agfa, Fujifilm, Tiger Coatings and EFI with applications from textiles and packaging to metal decoration.

The biggest advantages of AQ-UV inks are the fact that the ‘solids’ loading of the curable components are now substantially lower and the final cured ink film thus much thinner. Prints can look more uniform in gloss as a function of coverage, especially for deep colours. The labelling can be better too, although that is sensitive to the precise chemistry approach being used.

The problem is that a lot of the materials one typically makes a UV ink from are simply not soluble in water. This applies to the most UV monomers and almost all the photoinitiators. From an ink preparation perspective, the simplest way to go is therefore to choose from the smaller list of soluble materials and make an ink simply by mixing them together. The issue is that the water-fastness of the resulting film will be sacrificed by that solubility if the film is not completely cross-linked and so the intended advantage of the UV part of the mixture is therefore is partly lost.

As a result, the most common, and successful successful approaches tend to use reactive polymers, like “acrylated polyurethanes” as resin dispersions, sometimes also combined with an emulsion of photoinitiators and maybe a small amount of soluble monomer.

Process & design implications

In most cases the reactive materials only cure once the water has been dried away, allowing the polymer particles to get close enough to react. This means that the drying/curing is a two-step process, and the printer design needs to be customised to the individual ink’s properties.

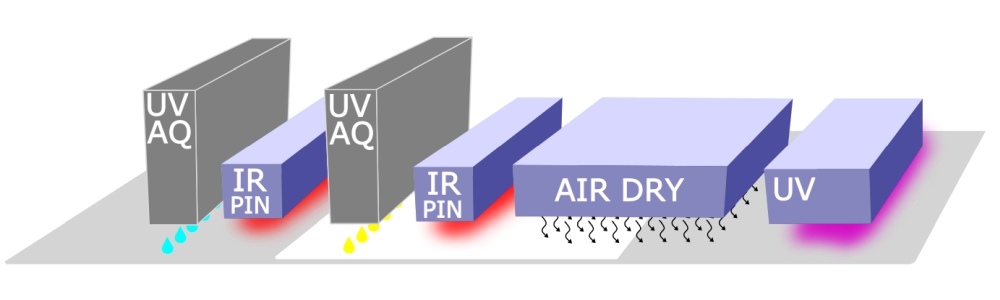

In scanning applications, the IR drying can be placed on to the head carriage, replacing the standard lamps in UV printers, much like the larger HP latex printers. A low power curing bar can be installed in the substrate feed direction. This is shown schematically in the images below and is how the Mimaki printer, using solvent-UV, worked.

The number of water-soluble photoinitators that are appropriate for a low-intensity LED source are again limited so, it is also conceivable that instead a 2nd carriage can be used for the UV curing if a higher intensity mercury lamp source is needed. The design could end up a bit like a Canon Colorado printer, using two scanning rails, one with head/IR and the other with the UV lamps.

In single-pass printers more space will inevitably be needed to ensure drying and that, as we know, will be very substrate/temperature specific. However, since the final UV curing will be instantaneous it can be placed just before the substrate merges, so does not necessarily add to the footprint. The schematic below suggests how different regimes for pinning and drying are conceivable.

Other UV-hybrid examples

We just mentioned solvent UV, which is subject to patents by Fujifilm/Sericol. In this case the curable polymer replaces the binder resin in what is, otherwise, a pretty standard solvent ink for wide-format graphics. As a result, the end use property can be extended, especially the water-fastness. INX also have a patent application on solvent-UV, in this case for printing aluminium cans.

Another UV-hybrid that comes up a lot is hotmelt-UV. We have not posted in detail about hotmelt inks since mentioning them in our introductory production inkjet series , but these phase-changing inks, sometimes called “solid inks”, have found niche application as etch masks in manufacturing application such as solar cells. Their major limitation, however, is that when exposed to nasty etching chemicals the relatively low-melting-point waxes of these ink types tend to lead to a limited etch time.

By adding UV curable materials into the formula, the resistance properties of the wax-based ink are much improved, and by choosing the right material, the ink can still be removed by the industry-standard alkaline developers.

The gel ink that is in the Colorado printer mentioned above is itself a bit like a hotmelt UV although, rather than being a wax that goes solid at room temperature, the gelling agent causes the viscosity increase significantly.

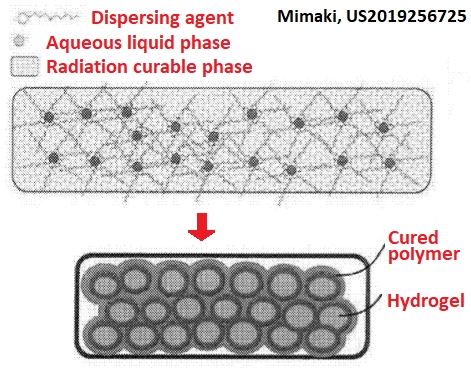

There are some other particularly interesting hybrid inks that have been proposed for 3D printing applications, the most fascinating of which that the author has encountered involves an emulsion of water in a UV matrix which forms hydrogels upon curing to simulate human tissue for medical training as shown in the patent picture below.

Beyond UV

Some of the same technology that has been used in water-based UV has also been proposed for electron beam curing as discussed in our last post. In this case the justification is similar: to remove the possible on migration of harmful photoinitiators. Such technology has been applied to flexo printing so there is a precedent, but the inkjet inks are much lower in viscosity so the potential for ink bleed is much worse when printing wet-on-wet. Sun Chemical have proposed that a tiny amount of less hazardous initiators may be used to overcome such issues in non-hybrid UV inks. Maybe the same is possible for “AQ-EB/UV” inks too?

So, is hybrid the best of both worlds? Well, not always due to the challenges of water solubility for example but it certainly enables some unique applications!

Comments

Thanks Mark. This was a very informative post.