The Inkjet Insight team spends a lot of time at print industry events, interviewing inkjet OEMS, customers who are evaluating inkjet for their business or have already implemented it. In past years, the conversation was dominated by transactional, direct mail and book printers. This year has been different. In the first five months of 2019, at events throughout Europe and North America, the conversation has been about using inkjet for high quality commercial print applications that were previously considered out of reach.

Many buyers this year are looking to complement or replace their offset production capabilities. This tells us high speed inkjet is gaining acceptance in a market with high print quality and color expectations. We are not talking about commercial direct mail, but high end, high value printing such as marketing collateral, magazines and catalogs. Often buyers are less concerned with press speeds than with how inkjet can provide the high print quality needed while integrating into their shops’ existing media requirements and finishing.

From our conversations, the key performance indicators (KPI’s) in considering high speed inkjet were:

-

- Reproducible Color Gamut

- 4+ color options or expanded gamut

- Image depth

- Minimal graininess in highlight areas

- Use of standard offset media

- Preference to sheet or roll

Inkjet has evolved to meet the KPI’s in this list to varying degrees. Some OEMs have focused on ink formulation, head technology, drying or a combination of all of them. Some manufacturers have developed entirely new inkjet approaches which apply drops to the media indirectly. Each solution provides different options in terms of ink chemistries, drying, varied production speeds, offset media compatibility, pre or priming media, post coating, ink values and 4+ color process.

To provide a comparison of these approaches, Inkjet Insight has drilled down on the family of presses from each OEM where the KPI’s fit within the specifications listed above. A list of “commercial ready” roll and sheet-fed inkjet devices that can complement or replace your conventional offset is included below.

| Manufacturer | Model Family | Paper Compatibility | Paper Feed | Print Method | Ink Type | Ink Configuration | Min Drop Size | Top Resolution | Gray Levels |

| Canon | ProStream | Offset uncoated, matt and gloss coated, inkjet-optimized | roll | jet to substrate | pigment based polymer | CMYK | 2 | 1200 x 1200 | 3 |

| Fuji | JPress 720S | Offset uncoated, matt and gloss coated, canvas | sheet | jet to substrate | aqueous pigment | CMYK | 2 | 1200 x 1200 | 4 |

| HP | Page Wide T Series HDNA | Offset uncoated, matt and gloss coated, inkjet-optimized, ColorPRO media series, paperboard | roll | jet to substrate | aqueous pigment | KCMY | 2 | 2400 x 2400, 1200 x 1200 | 5 |

| Komori | Impremia NS40 | Offset uncoated, matt and gloss coated, inkjet-optimized, textured, and embossed, synthetic substrates, paperboard, plastic | sheet | Jet to transfer | nanolink pigment | YMCK + 3 | 2.4 | 1200 x 1200 | 4 |

| Komori | Impremia I29 | Offset uncoated, matt and gloss coated, textured, and embossed, synthetic substrates | sheet | jet to substrate | uv | YMCK | 2.4 | 1200 x 1200 | 8 |

| Konica Minolta | AccurioJet KM-1 | Offset uncoated, matt and gloss coated, art and textured media | sheet | jet to substrate | uv | CMYK | 2 | 1200 X 1200 | 8 |

| Landa | Landa S10P | Offset uncoated, matt and gloss coated | sheet | Jet to transfer | nanoink pigment | YMCK + OBG + 1 | 2 | 1200 x 1200 | 4 |

| Landa | Landa W10P | Offset uncoated, matt and gloss coated, paperboard | roll | Jet to transfer | nanolink pigment | YMCK + OBG + 1 | 2 | 1200 x 1200 | 4 |

| Ricoh | Pro VC | Offset uncoated, matt and gloss coated, inkjet-optimized | roll | jet to substrate | aqueous pigment | CMYK | 1.8 | 2400 x 2400 | 4 |

| Screen | Jet520HD (also sold through Komori) | Offset uncoated, matt and gloss coated, inkjet-optimized | roll | jet to substrate | aqueous pigment | CMYK + 2 | 2 | 1200 x 1200 1200×600 |

4 |

We reviewed the specifications and print quality for over 65 inkjet models included on the Inkjet Insight Device Finder. Each series of inkjet presses were compared based on respective resolutions, minimum drop size, gray levels and ink configurations needed to address stated requirements. Inkjet models in the chart above specify the series, or family of equipment, and not always the specific model because the configuration options are considerable. Each offers different options based on the customer’s paper and coverage requirements. A book of business may require additional drying power or, perhaps, priming (in jetted or anilox form) or post coating. So, even though you may see the general specifications for an inkjet model, talking to the OEM’s about your specific KPI’s can open up options which address what matters most to you at the best price. Let’s further define the criteria used for evaluation.

Reproducible Color Gamut

For decades, commercial printers have provided 4 color process printing which can target industry color spaces such as SWOP, GRACol and FOGRA. These spaces have set our expectations for 4 color reproduction. Each device listed can, within specific speed, drying and media configurations meet or exceed industry color space standards.

4+ colors or expanded gamut

Commercial offset printing often provides more than 4 color options. Traditional devices may have spot colors or additional base colors to enable a range of colors which cannot be reproduced in a 4-color process. The series of presses in the table include traditional 4 color process options with inks that provide high chroma values, as well as 4+OBG (orange, blue and green) or spot color options. Expanded process chroma ink sets and additional colors can meet or exceed standard industry color spaces though each may require specific paper, priming and drying. Be specific about your color space and reproducible gamut requirements and test extensively.

Image Depth – Gray Level Resolution

A concern with inkjet is that colors can appear flat with less image and color depth than conventional offset. Gray levels of 8 or higher deliver the complex image depth associated with offset.

To achieve image depth in inkjet, a complex balance of resolution, bits processed per pixel and multiple drop sizes (gray levels) are balanced to give the illusion of multiple shades within a color area of the print1. These elements which make up the illusion of depth require much more processing complexity to process quickly and accurately.

In the past, inkjet’s high-speed variable data processing requirements imposed process limitations on producing better color depth. Inkjet technology has progressed, and image depth has improved significantly. Although inkjet still trails offset in some cases, the devices listed above provide the highest resolutions and gray level options with the smallest drop values. In combination these features provide deeper printed image depth.

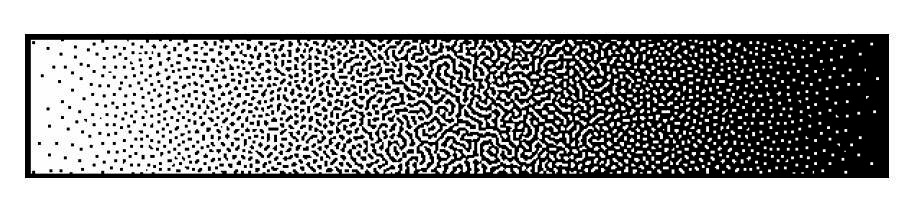

Reduction of Highlight Area Graininess

One of the biggest drawbacks of inkjet printing for commercial printers has been the graininess apparent in small reproduction images and in light highlight areas such as flesh tones. Inkjet’s use of FM screening can create a grainy appearance.

Your eye interprets graininess from “dots” and not from openly spaced patterns.

Tightly spaced dots create the appearance of darker tones, while open spaces create the visual effect of lighter image areas. When drops are farther apart, with more paper white showing through, we focus on the dot which makes us perceive a grainy appearance. To help minimize graininess, smaller drop sizes are needed. Devices which offer the smallest minimum drop size and/or use custom screening methods can create smoother tonal values reducing graininess in highlight areas.

Use of standard offset coated media and finishes

Conventional commercial printers do a lot of business printing on coated offset stocks. Coated offset papers are designed to repel water. It’s not a big surprise that this characteristic can create issues when working with inks which are mostly water. Inkjet OEMs have bridged this compatibility issue through advanced ink chemistry, including reducing the amount of water or using a different carrier, and the addition of jetted or flood coated primers.

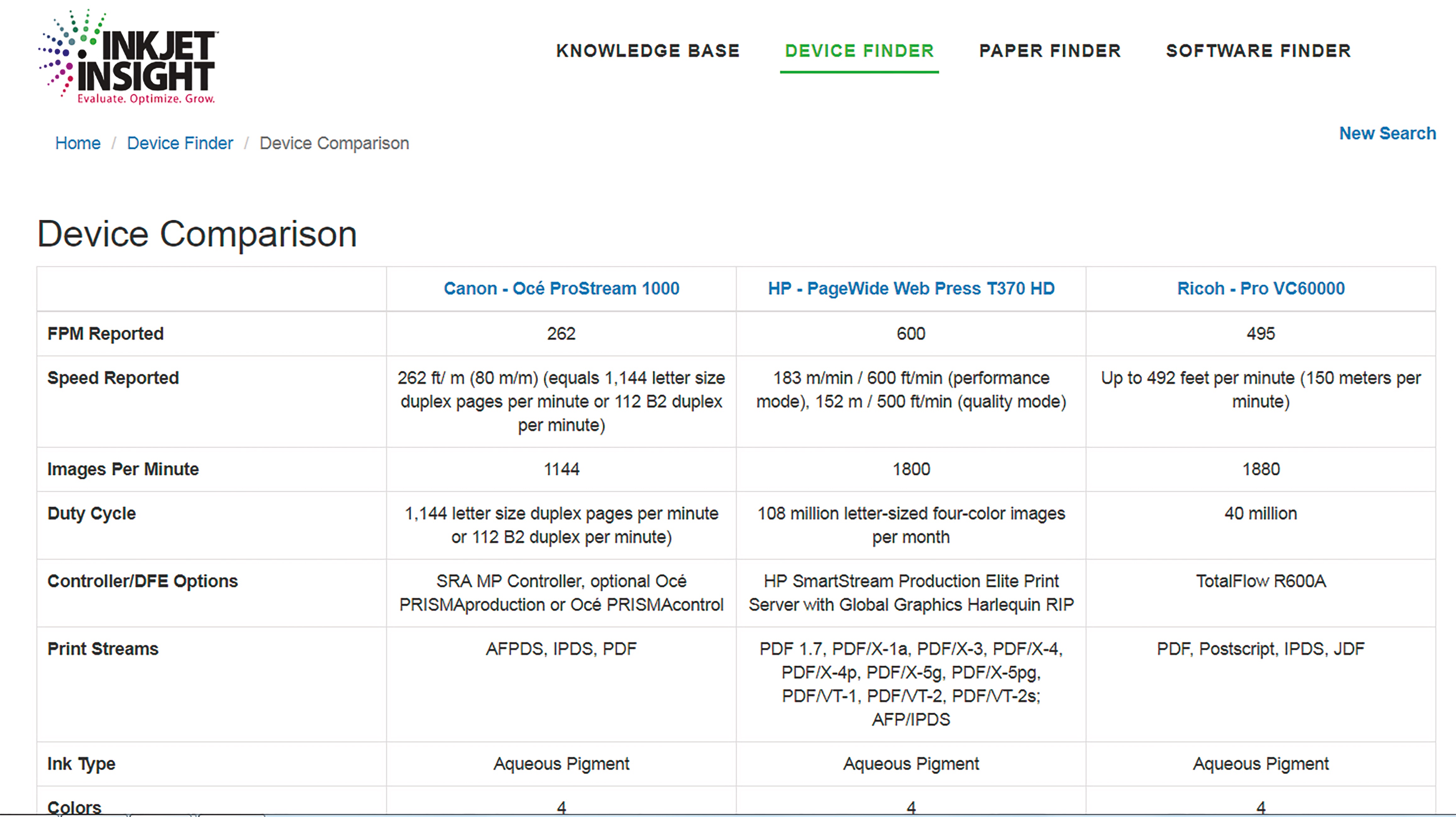

Partial screen capture of Inkjet Insight’s device comparison. Visit www.InkjetInsight.com to view more comparison data

Do Your Homework and TEST, TEST, TEST.

Each of the devices listed2 meet most or all of the KPI’s important in the commercial printing market. Some exceed commercial capabilities in one manner or another. Of course, your configuration and mileage may vary, so always do careful research and verify the process used to create samples.

Discussing your required KPI’s, paper needs, workflow, finishing and press room requirements with OEMs is critical to proper evaluation. Ink coverage and color space target requirements should also be discussed in depth because they affect production speed requirements and non-porous media compatibility.

Go to InkjetInsight.com and create your own inkjet device comparison and review the items which are important to you, your sales teams and of course your customer. You can also download test files and tint books.

Want to learn more? Visit www.InkjetInsight.com and create your own custom side-by-side comparison or talk with the Inkjet Insight team to gain more, you know, Inkjet Insight.

Note to OEMS: Think your technology should have made the cut? Check your device listing on Inkjet Insight to ensure your data is complete and up to date.

1. See Inkjet Insight: Understanding Gray Levels www. https://inkjetinsight.com/knowledge-base/understanding-gray-areas-inkjet/).

2. Many OEMs make significant upgrades to devices without changing the device name and we do not update previously posted articles. Check our Device Finder for the latest specifications.