A wise man once said, “whomever figures out the chem-stack wins”. This has never been truer than for the flexible packaging market. Flexible packaging is composed of varying substrates sandwiched on each side of what is called the chem-stack. The chem-stack is a combination of chemistry which serves many purposes for lamination, ink adhesion, wet-out, print, color quality and bond strength.

Digital inkjet printing has impacted most industries over the last 10 years, but flexible packaging has been the slowest to integrate inkjet due the sheer complexity of the materials used and the challenging chemistry requirements to ensure successful lamination.

Complex Materials

Flexible packaging is plastic packaging made from a formable and stretchable film printed and converted into bags, pouches, sticks, liners, wraps, and other products. The plastics most commonly used in flexible packaging applications are low- and high-density polyethylene (PE-LD and PE-HD) and polypropylene (PP).

There are three main types of material used in flexible packaging: paper, film, and foil. Each has its own unique benefits and drawbacks. Paper is a porous, natural material that is easy to print on and recycle. Whereas the poly substrates are non-porous, have stricter recycling rules and are harder to print upon digitally with aqueous inks.

Overcoming Substrate Challenges

Printing on film and foil requires a combination of chemistry and application conditions suitable to create the required bond strength for the packaging. For the inkjet market UV and aqueous pigment are the two chemistries most utilized. Although UV inkjet inks have fewer issues with printing on these non-porous substrates, they can be undesirable because of migration contamination caused by its ink chemistry, incomplete cure, larger drop sizes and jetting speed limitations. Aqueous inkjet inks also have their share of challenges as they require additional fluids pre-jetting such as pretreatments, binders, and primer applications for ink adhesion, drying and lamination bond strength.

These chemistry challenges don’t stop at the compatibility of the various fluids when combined. Chemistry must also account for their optimum level of surface tension variation, application thickness, application type, speed and drying previous to the inkjet ink application. All fluid chemistry such as base and primers, four color inkjet inks, flexography ink application, and adhesives and their optimum condition are included in this highly complex system called the chem-stack. Managing all these moving parts means the success or failure of the lamination process as well as print acceptance.

Print and Color Quality

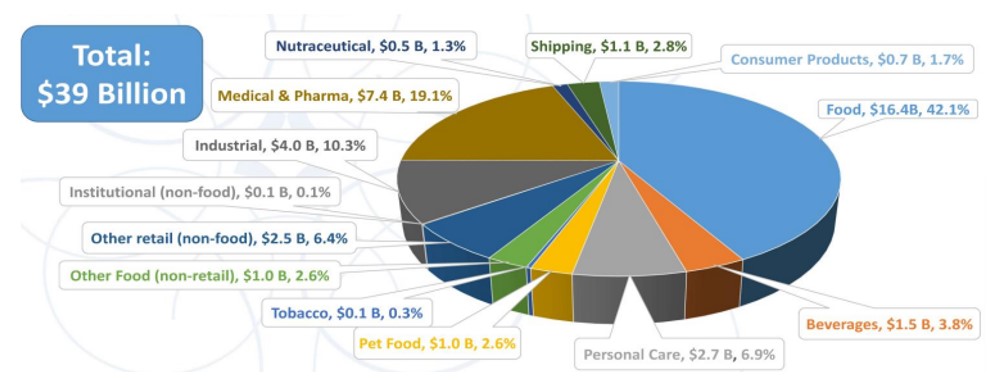

Based on FPA 2023 State of US Flexible Packaging Industry survey, 42.1% of the $39 billion flexible packaging market is printed for the food packaging market.

Source: FPA State of the U.S. Flexible Packaging Industry Surveys (converter member and non-member. Average used for calculations: N=16.

This requires flexible packaging to use non-migration inks that can produce highly detailed print quality without highlight graininess. These inks must also be capable of producing a wide enough color gamut to provide detailed highlight/shadow ranges that deliver life like and appetizing image reproduction even when viewed at close range.

In addition to the image quality requirement, flexible packaging color quality should produce the largest gamut possible to incorporate demand for matching corporate and brand colors.

Customer Market Needs

Market needs have been changing quickly over the past 10 years. Brands are required to respond to markets through changing packaging graphics, messaging, and food and carbon footprint regulations, requiring more SKUs with lower print quantities.

Current brand campaigns using flexography for their packaging have seen up to 45% in product waste as run requirements with a minimum of 3,000 lin/ft, averaging 25+ days to finished production are the norm.

Fast-growing markets are creating more competition for current and emerging markets which make product launch, regulatory and recycle reporting expensive with the current flexography high run and lead time requirements. When small quantities are required for specific timely promotions, printing digital can expand the promotional window.

Winning at Flexible Packaging

Paper Converting Machine Company (PCMC) is part of the Barry Wehmiller Converting Solutions (BW) family. Acquiring technology companies serving the packaging and mailing industry, the BW family manufactures varying equipment such as Fusion flexo-presses, mail solutions, pouch-making lines, in-line print camera systems and their new ION press for flexible packaging.

PCMC seems to have solved the chem-stack puzzle for flexible packaging with their new ION platform. Working over the past year with internal manufacturing, chemists and vendors, the ION team has developed a repeatable chem-stack “recipe” for substrate, ink compatibility, wet-out, ink balancing and drying on non-porous PET poly flexible materials printed at high speeds. This recipe creates the perfect condition for reproducing detailed text and imagery on finished, laminated packaging.

The ION is a digital/hybrid flexible and folding carton solution designed to remove industry barriers of quick change, quick turn, on demand variable printing barriers for flexible packaging.

PCMC ION shown with 2 flexo stations/CMYK inkjet digital/2 flexo station configuration with in-line lamination

The ION is highly configurable. Flexo decks and modular extended drying can be integrated for pretreatments, OPV’s or ink stations pre and post of the Memjet DuraLink 2.1pL, CMYK aqueous pigment thermal print heads. Available with inline lamination, the ION is offered in web widths of 32”, 36”, 42” and 52 utilizing 42” OD roll, running up to 400fpm at 1600dpi cross web and 790, 925 or 1600dpi down-web resolutions (speed dependent).

The ION jets a 2.1pL drop which eliminates any graininess or ink plugging typically seen when reproducing challenging highlight/shadow balance of flesh tones.

Balance between highlight/shadow without 4% plugging from dot gain. Magnification @ ~ 2.5µm/pixel PIASII.

Using high chroma aqueous pigment process inks expand the color gamut beyond CRPC6 opening the color simulation Pantone library to 72% using only CMYK process colors. If there is a color requirement out of gamut, the color can still be printed on target by a flexo station.

Market need is the ION’s core focus, creating a digital quick change print process, multiple SKU’s can be printed across the web, while honoring profitable lineal feet requirements. Ganging jobs allows graphics to change on demand using inkjet, while any primers, OPV’s and spot or flood ink requirements use flexo.

The PCMC division of BW Converting Solutions showcased their new technology the week of April 22, 2024, at their Open House in Green Bay, Wisconsin. This event consisted of industry and vendor expert presentations, customer breakout sessions, Fusion CI press demos and PET flexible packaging printing on their new digital hybrid ION press.

PCMC designers created a series of flexo challenging graphic packaging printing on 48ga PET in reverse with a flood flexo white. Samples pulled from the rewind showed high quality detail which the small drops can achieve at a printed resolution of 790×1600 at 400fpm.

Flexible packaging samples designed by PCMC

Hosting 130 customers across various lines of package printing, BW’s open house proved to the market this traditional, flexography focused manufacturer is embracing the need to merge digital inkjet into conventional processes to satisfy the requirements which their customers are facing today.