After a year of pandemic news and difficult trading it is good to hear that major players for graphic printing equipment keep on investing and innovating. Ricoh’s President and CEO, Jake Yamashita, recently pledged that the company will spend approximately $1 billion in R&D each year. Ricoh also stated that inkjet is the future, although investments in toner technology will continue. Ricoh stated as well that the company’s aim is to make inkjet technology available to a wide range of customers. The company is about to launch a “global ecosystem” or community to educate on the new press and inkjet in general. Ricoh is an established player in roll-fed inkjet and is now entering into sheetfed inkjet printing as well.

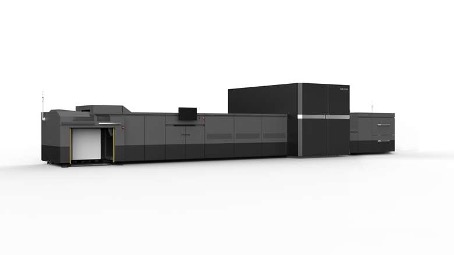

Since late 2020 there has been a series of teasers and videos hinting on the new Ricoh B2 sheetfed inkjet presses, drumming up anticipation for the official launch event. On the 5th of May Ricoh launched the Pro Z75 and divulged more, although not giving away all details about their new inkjet press yet.

The Pro Z75 has been eagerly anticipated as it is targeting the most dynamic market in printing press technology: production sheet-fed inkjet. The Pro Z75 is targeted at commercial print, although Ricoh expects some interest from in-house print as well. Availability is still some time out, however. The first beta site is likely to be at a US customer. Ricoh is said to run demos at its customer experience centres from Q1 2022 with commercial availability planned for Q2 2022.

The specs

The Pro Z75 is based on a new platform, designed from the ground up, although ink, inkjet head and drying technology is based on the technologies and experience gained with the Pro VC roll-fed printer series.

In fact, the Pro Z75 has a maximum sheet size a bit larger than B2 with 585x750mm or 23” by 29”. As expected for a press targeting commercial print, coated and uncoated paper is supported, both as inkjet treated or standard offset versions. Weights from 60-400gsm uncoated or 73-400gsm coated are possible.

The press prints in CMYK with a top speed of 4,500 B2 sheets/hour single sided printing, or 2,250 in perfecting mode. The press uses newly developed Ricoh multi-drop printheads based on the VC 60000/70000 heads. It allows printing at 1,200 by 1,200 dpi resolution. A new aqueous ink set is used as well, which is claimed to cover a wide color gamut.

The Pro Z75 is driven by a new frontend developed with EFI and features a large touchscreen display for the operator.

Paper is fed from a feeder module with two paper trays, similar to established high-end toner presses. This would allow drawing paper from multiple sources and switching papers without stopping the press. It would allow proofing on a different paper in-between other jobs as well. While Ricoh did not comment on it, adding in-line finishing modules should be possible. The delivery has a high pile and proofing tray.

The press is not a small device, with a length about 12.5m or 36 to 40 feet – depending on the exact configuration. This is comparable to a twin roll-to-roll Pro VC 70000 line. Ricoh however stressed the sturdy built of the press to give best quality and durability.

Ricoh sets a maximum duty cycle of 2.6 million B2 impressions per month, which translates roughly into 10 million A4 a month. In comparison the Pro C9210, the top toner model, has a duty cycle of 1.75 million A4. The recommended volumes are a bit lower with 250k to 1.25 million B2 impressions.

Our take

Initially Ricoh aimed the Pro Z75 to be the fastest B2 inkjet press. This has just been spoiled by Fujifilm upping their speed of the JetPress (JPress in US) 750S to 5,400 B2 sheets per hour. The speed of Z75 is on par with the HP Indigo 100k press, which offers 4,500 sheets per hour, although the 100k can increase the speed to 6,000 sheets/hour in the EPM mode (printing 3 colours). Granted that the HP Indigo is using liquid toner – it will play in the same competitive space. Still the Pro Z75 is fast and tops the speed B2 inkjet models offered so far.

The design of the Pro Z75 is a refreshing alternative to the existing B2 inkjet press designs. With a multiple tray feeder, the potential of in-line finishing and output pile options the Pro Z75 is more akin to a digital press than an offset press. As it allows changing papers while the press is running, mixing media or adding finishing it can make short run printing a lot more efficient. However, it does sacrifice this for footprint and a design familiar to an offset press operator.

The specs hint at very good print quality and Ricoh confirms that it rivals “offset press quality”. Ricoh mentioned that the Pro Z75 will be able to move into packaging print, but with a maximum weight of 400 gsm this will be limited to light folding carton board only. On the low end of paper weights being able to print on 60 gsm paper is quite advantageous and not many presses can go down that low.

Ricoh assures that the press will be competitive, have low operating costs and competitive investment. At the moment there are no details available on these critical factors. Nevertheless, the facts divulged so far sound very promising and we wait for more details and feedback from the beta sites.

Comments

Be intersting to see if the JetPress runs at 5,400 sph at maximum resolution?

It most likely will not. Fujifilm talked about 5,400 sph in “performance mode” – which is the code word for lower resolution