In this installment of “Let Data Drive your Print Quality Comparisons” we will discuss the importance of chroma and how it’s defined within the context of print quality analysis. When talking with commercial printers, chroma is one of the most important aspects of printing.

What is Chroma?

Chroma measures a color’s purity, intensity or saturation and is affected by the individual and combined printed color Density, which we discussed last week in Objective Ink Measures – Optical Density. When one describes a color as “clean or dirty”, they are likely referring to its Chroma.

Chroma is measured with a device called a color spectrophotometer, measuring one printed patch at a time or in an automated feed device.

A higher chroma value for CMYRGB represents greater purity of a color. Even though black (K) lacks chroma, we still capture it to understand aqueous inkjet interaction with papers which include high OBA’s. OBA’s can give K a haze when absorbed which can affect quality for some application segments such as books.

Munsell 3D color model

Chroma values change from the center outward

Chroma measurement is not captured in this case for process control, but to help understand the amount by which a paper affects a printed color or tint. Understanding how the flow of the ink, and drying aspects of an ink, assists paper mills, printers, sales, marketing and designers to compare the differences in ink to paper interaction between inkjet and offset. Offset chroma is affected by paper to a lesser degree than inkjet because offset ink sits on the surface as a film. Offset inks still may have some dry back which affects chroma. Offset ink chroma values can be changed by adjusting the actual ink formulation. This is not so easy for inkjet.

Color chroma for high speed aqueous inkjet, by comparison, is affected by every paper on which it jetted. As we have mentioned many times, aqueous ink dries by a balance of absorption and evaporation of the ink carrier (water). Paper plays a big part in the drying formula. Paper used for high speed inkjet must have a level of porosity even if it is a coated sheet. Controlling the compatibility of the ink and the sheet determines how much ink and colorant stays on the surface. The ability to increase an ink’s chroma depends on many factors:

- The Ink Itself– Different inks are manufactured with varying colorant values within the fluid. Depending on the drop size(s), viscosity and other factors, the level of colorant within an ink may be higher or lower to ensure proper jet-ability for a particular head and machine speed. This combined jetted colorant is a fixed value which cannot be altered without a high degree of complexity by the OEM.

- Paper Porosity– Ink is water based and dries by different levels of absorption into the paper. When an ink drop is absorbed, it takes on the paper color to various degrees, as well as any level of dirt count found within the stock. An ink may be a high chroma ink when described by the inkjet device manufacturer, but once it is printed, the level of chroma can be completely different.

- Paper Treatment– The level in which the chemistry of the sheet can bind the colorant before the carrier migrates into the sheet. Colorant which stays higher on the paper surface will result in better chroma (cleaner colors). This is why you may be able to print your target brand color more accurately on a low absorbent inkjet coated media than an absorbent treated or uncoated media.

- 100% Printed Ink Density– The 100% density value of dried, printed ink compatible with the media to ensure proper spread and drying.

- Volume Paper Color – The pattern in which the drops form when jetted on to the sheet also will affect a combined printed color chroma of an area. The pattern which is used for aqueous inkjet is called a “dither pattern”. This is a random pattern which places drops farther apart or closer together allowing more or less of the paper to show through to give the optical illusion of a tint change. Chroma will be affected by how much of the paper is exposed through the pattern due to varying color, whiteness and brightness of individual papers.

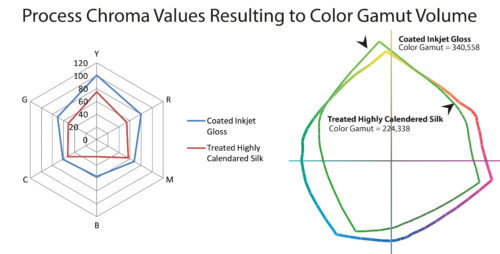

The chroma values for process CMYKRGB values is just one of the many variables which affect the overall reproducible process color gamut of a print device and paper.

To see the direct affect of ink and paper on chroma, we have measured the same coated and treated stocks from the optical density article, charted these values for our 100% CMYKRGB and included the gamut chart to provide a visual correlation for your viewing pleasure.

Visual Chroma Comparison with Values

Measuring and comparing your chroma numbers through your paper testing process creates a better understanding on why colors look cleaner or dirtier from one paper stock to the next. If you understand the cause and affect of aqueous ink on paper, you will better explain the value of using one paper over the other. It’s a win win.

Remember… Measure twice. Print Nice

Mary