In “We love fast inkjet” I introduced the key levers that inkjet OEMs can use to increase production speeds along. These include printheads, electronics, inks, drying, and transport. The focus of that article was printhead technology, electronics and drop control.

This article discusses the remaining levers and the different challenges faced when developing sheet-fed presses. To gain insight on the complex development challenges OEMs face, I spoke to experts from Canon, Kodak, Kyocera Document Solutions, and Ricoh.

For context, the discussion is limited to CMYK production inkjet presses using water-based inks serving the document market rather than the broader industrial/packaging market which has many more substrates and ink chemistries to consider.

Substrate and printhead driven ink options

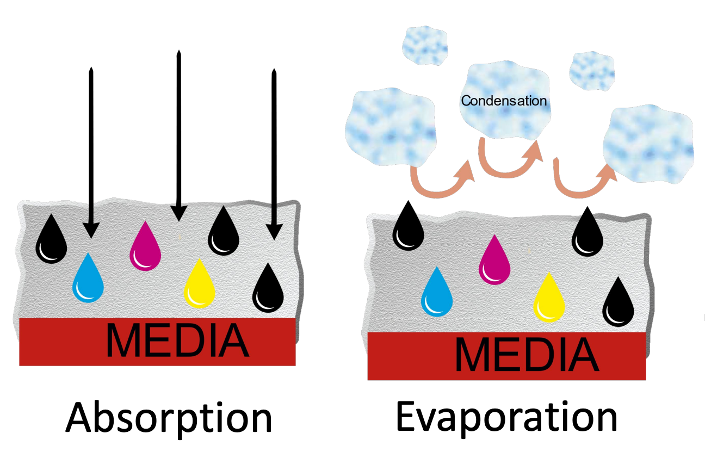

There is a tug of war between keeping ink at a low enough viscosity to jet without clogging printheads while also incorporating an appropriate level of colorant in a carrier that can be dried without damaging the substrate. Water based inks, particularly those used with piezo heads, typically have significant levels of humectant to help keep inks from drying inside the printhead and causing clogs or jet-outs. Randy Vandagriff, Senior Vice President, Print Eastman Kodak Company notes that “Anti-drying agents (humectants) make it much more difficult to dry when the ink is not able to absorb into the substrate, therefore, lower speeds are required.” Both the continuous inkjet (CIJ) printheads used by Kodak and the thermal inkjet (TIJ) printheads used by HP intrinsically rely on fewer humectants and “cleaner” ink chemistries than those used in piezoelectric printheads. TIJ heads which use heat to eject drops are not friendly to many chemicals. CIJ printheads due to continuous recirculation have less need for humectants. The choice of printhead impacts ink chemistry, which in turn impacts drying approaches. Supporting multiple types of media adds more variables to the mix. Dr. Martin Berg, Product Line Manager Continuous Feed with Canon sums up the challenge, “Inkjet printing is always a balance between ink, printhead and drying.”

Supporting coated media at speed

Without a doubt, aqueous ink chemistries were far less complex when presses were only targeting porous papers, or even better, inkjet treated ones. However, tackling coated stocks was a requirement for inkjet to grow into the most lucrative print markets. Todd Potrykus, Senior Program Manager, HPS Global Product Marketing with Ricoh noted that the approaches taken are largely determined by whether coated paper is a requirement. He said, “The characteristics of the ink, and particularly the complexity of the dryer, are quite different. Achieving 150 m/min with high color coverage on gloss coated paper is a very different proposition to drying at even much higher speeds on uncoated paper. “ Ricoh also introduced temperature control in the form of liquid cooling to their Gen5 Ricoh piezoelectric printheads on their latest press to ensure jetting stability at higher speeds. Ricoh has developed a highly sophisticated ink that enables printing on uncoated and most coated media without the use of pretreatment and offers an optional undercoating unit for challenging coverage/substrate combinations.

Whether you call it primer, pretreatment, or undercoating, adding another fluid to the mix puts more pressure on drying and can adversely impact speed. If precoating is applied from a separate unit, as opposed to jetted inline, that precoating unit needs to have the same speed and uptime and the press to achieve productivity goals. Since ink, ink coverage and media play such a pivotal role in determining speed limits, many OEMs not only use multiple types of drying but offer customers multiple options for the number of drying units deployed based on media and coverage requirements. OEMs may also extend the length of the paper path to extend the dwell time and allow air circulation to enhance other drying technology. However, this has the downside of creating a larger press footprint.

See “Understanding Drying Technology” webinar replay for more on drying.

Transport and motion control for web and sheet fed presses

With all the stresses and strains placed on the printed media through wetting, heating, and drying the most challenging may be moving that tortured product through the process in a precisely controlled manner and at speed. Dustin Graupman, Senior Director Ink Jet Division, Kyocera Document Solutions says, “Different than offset and toner, a major benefit of inkjet is that is it’s contactless technology. The benefit of non-impact is reliability, but the drawback is paper control. Paper handling must ensure a consistent and predictable distance between the printhead and the substrate. Curl or cockle of both virgin paper and simplex/duplex is controlled through a tight web configuration where with cut-sheet it needs to be managed completely differently.”

In a continuous feed environment web tension must be managed to keep paper stable without stretching or tearing and control side-to-side registration. Mechanics are needed to keep the substrate at the appropriate distance from the media with an increasing range of thickness, typically between 40 and 300 gsm. Productivity is also enhanced when the system enables the press to begin printing on ramp-up rather than wasting time and paper waiting for the press to reach full speed. Since roll changes become more frequent as presses go faster, splice detection is needed to integrate automated winding systems for maximum productivity. This is an area where HP and Kodak have led the pack,

Todd Potrykus calls out differences between developing web versus sheet fed solutions, “In a continuous device you can use tension from beginning to end to keep the paper under control and moving in a straight line, but with sheetfed you are continuously handing the sheet from one control mechanism to the next . The technology that takes the paper from the feeding drawer is different to how it is controlled through the imaging unit, and this is different again to how the paper is moved through the dryer. Even turning a sheet to print the second side is more complicated.” Ricoh recently brought their first sheetfed inkjet press, the Ricoh Pro Z75 B2 press to market.

Bas Smeets, Product Line Manager Sheetfed inkjet with Canon notes a few challenges sheet fed inkjet developers face, “One must avoid sheet deformation, especially in duplex. It is challenging to keep the sheet flat during printing, drying, and transport and final output no matter what substate is used or what the ink load is.” Canon has delivered multiple generations of their VarioPRINT i-series and iX-series B3 presses which have multiple drawers. “We must support a wide variety of media sizes and types, sometimes within the same job, while maintaining productivity and quality, independent of substrate, application or ink load.”

Assessing the cost of speed

Adding more printheads, electronics, precoating, complex ink formulations, and drying to enable speed comes at a cost. Getting to the next incremental speed level could require a physical footprint, price tag, or both that are out of step with the target market. When Kyocera entered the B3 press market with their TASKalfa Pro 15000C they did not try to leapfrog competitors in terms of speed. Graupman says, “We intentionally targeted the 150ppm range as it seemed to be an unaddressed productivity range for the overall investment to acquire inkjet production capabilities. We expect to pursue increased speed in future platforms.”

Keep in mind that cost can come in the form of a higher purchase cost, higher consumables costs, or increased maintenance requirements. OEMS may choose between printheads with longer life, or ones that enable less expensive ink. They may develop a more expensive and chemical-intensive ink that eliminates the need for pretreatments or opt for a “cleaner” ink and the option to apply pretreatment when needed. In the past year we have seen the range of inkjet OEMs pull various combinations of levers to deliver incremental improvements in speed for high coverage applications without sacrificing quality. In assessing these improvements, it is important to look at the proportion of media and jobs that can be run at top speed rather than simply the top speed of the press.