Sponsored Content from Kodak

While printheads, inks, drying, and software all play a role in print quality, this article focuses on the evolution of printheads in delivering improved results as production inkjet expands into new areas.

When single-pass, production inkjet first became commercially viable, graphic arts applications were purely aspirational. In satisfying the needs of high coverage, high color applications, printheads must now deliver both higher resolution and precision. There are many challenges to achieving that combination which will be discussed relative to different printhead technologies.

Printhead technologies used for graphic arts production

The categories of printheads used for graphic arts printing include piezoelectric, thermal, and continuous inkjet (CIJ). Piezoelectric and thermal printheads are called Drop-On-Demand (DOD) technology because they are only activated to eject a drop of ink when needed in contrast with CIJ heads which are continuously jetting.

- Piezoelectric printheads deliver an electric pulse to a piezo crystal to expand and contract the ink chamber in the nozzle creating the necessary pressure to propel a droplet of ink.

- Thermal printheads use a heating element in the nozzle (rather than a piezo crystal) to create a pressure pulse, propelling a droplet of ink.

- CIJ printheads circulate ink through the printhead continuously. As ink exits the nozzle, the stream is separated into droplets for printing and those to be recirculated.

Illustration of CIJ printhead drop circulation. Source: Kodak

Don’t confuse the unique, continuous droplet recycling capabilities of CIJ printheads to with those of “recirculating” DOD printheads. Recirculating DOD printheads provide a constant flow of ink inside the printhead to help prevent the nozzles from drying out and clogging which can result in jet-outs and other defects. Recirculation also helps to keep the ink at a more consistent temperature which is particularly important for thermal printheads. This capability is a relatively new and complex feature for DOD printheads but is inherent with CIJ printheads.

All these printhead technologies have evolved over time to pursue different quality measures through different approaches.

The evolution of print quality

Fifteen years ago, the primary application segment for production inkjet was monochrome customer communications where 300 dpi resolution was adequate for most needs. As inkjet has progressed in addressing more challenging applications the emphasis on different print quality measures has also evolved.

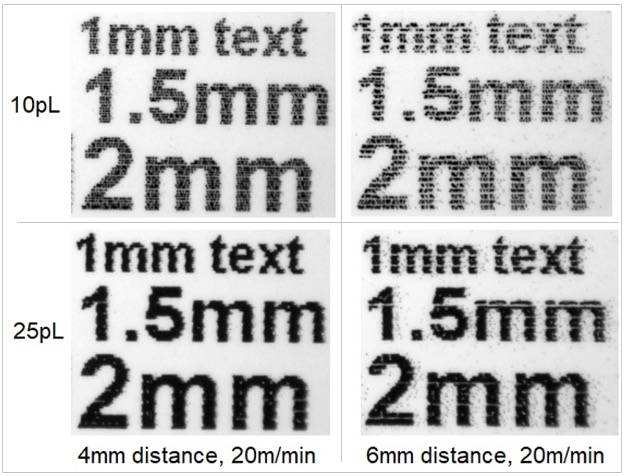

In the early days, printhead manufacturers focused on increasing native resolution. To increase the number of drops per inch (dpi) the drops themselves must get smaller. As the dpi ceiling has been raised from 300 to 600 to 1200 and higher, the drop volumes have steadily and proportionally reduced. However, smaller drops are more susceptible to the wind shear caused by the motion of the substrate below the printheads. When a long tail separates from the primary droplet, in breaks off into a “satellite” that hits the substrate after the primary drop causing blurring.

Example of reduced jetting accurate and increased satellites with piezoelectric printheads at higher throw distance. Source: Mark Bale ©INKJET ACADEMY.

To avoid print defects from air turbulence, either the throwing distance between the printhead and the substrate must be reduced, or the jetting velocity must be increased. The need for a pulse to create a drop limits the ability of DOD printheads to increase jetting velocity thus requiring the heads to be positioned closer to the substrate than with CIJ heads. This necessitates additional equipment to raise heads in support of automation features like non-stop winding and splicing to prevent damage to the printheads.

While higher resolution is the primary consideration when evaluating the print quality of text, higher grayscale or bits per dot is critical for optimizing images, particularly photographic ones. Binary printheads vary the positions of dots of fixed size, assisted by an error diffusion algorithm, to match the density variations of a photographic image. With a single dot size, unless the dots are extremely small, there is limited ability to avoid visible “staircasing.” However, the use of multiple volumes produces a range of drop sizes on the media enabling improved tonal range and edge clarity.

Leading piezo printhead manufacturers initially approached this challenge by enabling “dynamic drop on demand” jetting of three or even four, distinct drop sizes. However, the use of smaller drops and multiple drop sizes requires higher jetting frequency which can compromise productivity. For that reason, most graphic arts oriented piezo printheads today jet only two distinct drop sizes. It is also possible to interleave high drop weight nozzles with low drop weight nozzles in the same printhead as HP has done with their HDNA thermal printheads. When all nozzles are used, excellent grayscale reproduction is possible, but consistent formation of the smaller drops is challenging at high-speed causing a tradeoff between speed and quality where top quality is only accessible at lower speed and vice versa. A third method of optimizing image reproduction is through the ability to deliver small drop volumes and deliver multiple drops accurately to the same spot to create larger dots. This approach requires the higher firing frequency and drop velocity unique to CIJ printheads.

Print quality is also subject to the health of the printhead. Even the highest resolution printheads with precise drop formation will deliver substandard results if nozzles become clogged due to ink drying inside. Capping of printheads during downtime can help avoid this issue, but there are other ways for nozzles to become clogged. Printheads positioned close to the substrate can be negatively affected by dust and debris from the media moving below them. Some press manufacturers add inline print quality systems to dynamically compensate for potential jet outs using redundant nozzles. All of these important, yet expensive, systems can be avoided by using print-heads that sit further away from the substrate, fire at higher velocity, and recirculate ink to avoid clogging.

Kodak adopts a unique solution to print quality challenges

Kodak is unique in their adoption and optimization of CIJ as the foundation of their inkjet technology stack. Kodak has been manufacturing their Stream CIJ printheads since 2008. Stream printheads use thermal heaters that change the surface energy of a continuous flow of ink to form drops. Air deflection separates the drops for printing from those to be recirculated. Kodak Stream printheads deliver the speed necessary for integration with offset, flexographic or gravure presses and to power Kodak’s highest productivity presses the KODAK PROSPER 6000 and the PROSPER 7000 Turbo. The latter is the fastest inkjet press on the market today running at between 650 and 1345 fpm (200 to 410 mpm) with resolutions from 600 x 450 dpi up to 600 x 900 dpi.

Randy Vandagriff, Senior Vice President of Kodak’s digital print business explains that Kodak’s CIJ printheads can generate different drop sizes at the same frequency. “This enables us to modulate the drop size based on resolution and speed without the addition of more nozzles. Our significantly higher drop generation frequency, driven by highly pressurized continuous inkjet, enables the flexibility to trade off resolution, speed, and drop size at the same frequency. Kodak can deliver full pixel ink coverage at 600 dpi, 900 dpi, and 1800 dpi, all of which require different drop sizes to meet full page or pixel coverage.”

Kodak also has a newer line of CIJ printheads, ULTRASTREAM, that deliver more than 400,000 drops per second per nozzle, with a print frequency 2 to 3 times faster than the fastest DoD technologies. The ULTRASTREAM heads use a charged electrode, rather than an air stream, to deflect drops for recirculation. ULTRASTREAM is used in the KODAK PROSPER Ultra 520 Press to deliver a resolution of 600 x 1800 at up to 500 fpm even on coated stocks. Vandagriff notes, “As we developed ULTRASTREAM we were able to drive manufacturing costs down due to the scalability of the ULTRASTREAM design. This scalability also enables future drop frequencies that are twice as high as today, approaching 800 kHz which means we have a lot of running room left for improved image quality, speed and productivity. Kodak has also demonstrated the scalability of our cross-track density resolution, which could allow Kodak to go to 1200 dpi resolution and maintain or improve speed capabilities over current competitive technologies.”

Another feature of Stream and ULTRASTREAM printheads is the uniformity of drops produced. The firing velocity and very round drops coupled with precise drop placement yield accurate print quality without the satellites and mist attributable to the impact of air turbulence on DoD jetting systems producing small drop sizes.

Source: Kodak

The elements of Kodak’s CIJ technology, such as continuous recirculation and high jetting velocity cited for enabling precise grayscale printing also enable operation at top speed with fewer nozzles, reduced down-time for maintenance, and support for smaller pigment particle sizes without fear of nozzle clogging. As production inkjet continues to challenge the supremacy of offset printing for graphic arts applications, printheads will continue to evolve to meet more demanding requirements. Arguably, continuous inkjet printheads have an inherent advantage in scaling efficiently to meet these needs. Kodak has the unique advantage of a platform strategy built on continuous improvement of continuous inkjet printheads.