Sponsored by Kyocera

When evaluating products and services, the fine print is usually bad news. “Reading the fine print” often uncovers that product performance, under some circumstances, is not quite as good as promised in the glossy brochure or product video. The opposite is true with the promotion of the Kyocera TASKAlfa Pro 15000c. A close read of the specs shows that Kyocera has actually been under-promoting some capabilities of the press, starting with its resolution. The Kyocera website and product brochures consistently describe the TASKAlfa Pro 15000c as a 600dpi press but, if you read more closely, you will find that the standard resolution of the Kyocera printheads can be boosted to 600×1,200dpi at slower speeds. This can help with the second kind of fine print that is so important to most customer communications and direct mail applications – actual fine print.

You may be familiar with the practice, used by many other inkjet OEMs, of listing the highest possible resolution and the highest possible speed available, but making you read further to find that you can’t have both at the same time. Fred Morrone, Senior Manager, Production Inkjet Marketing at Kyocera said that the company consciously took a different approach, “This was the first press that we were bringing to market directly and we wanted to under promise and over deliver.”

Resolution is not the only aspect where the company under promised. For a press with a standard configuration available at well under a half million USD, the TASKAlfa Pro 15000c delivers a surprisingly high level of productivity, duty cycle, and color quality as well as a range of technical capabilities, such as automatic nozzle compensation, that have only recently been offered on more expensive inkjet presses.

The Fundamentals

Priced to compete with toner devices running at upwards of 100 ipm, the press typically sells for less than half the price of sheet-fed inkjet presses running in the 300 ipm range. The main limitation when comparing with those toner and inkjet competitors is that the TASKAlfa does not support offset coated stocks. However, the high end of direct mail and commercial work where coated stocks are required have not been the target markets for the press. This is not to suggest that the press doesn’t deliver high quality output, in fact, it can consistently hit G7 color targets on offset uncoated stock. This is not surprising given the long track record of Kyocera piezoelectric printheads driving high quality in other OEM’s presses. To offer a further boost to its already strong performance, all Pro 15000c versions of the press come standard with the Fiery FS300 Pro controller (base models of the TASKAlfa are configured with a Kyocera controller as standard.)

Support for a wide range of media weights is a strength, with papers as light as 56gsm and as 360gsm supported including 10pt postcard stocks. This is accomplished with a combination of highly efficient drying, friction and vacuum feeder technology, and a contact image sensor (CIS) to control registration and ensure that paper edges remain smooth throughout processing. The CIS prevents printing on any media where corners are broken or punched, as well as ensuring that ink is only jetted on media.

In addition to supporting a wide range of media weights, the press can support paper sizes up to 13×19.2 inches as standard with an optional banner tray for extra-long paper sizes up to 48 inches. It also supports feeding of irregular surfaces such as embossed paper and tabbed media. The press can be configured with up to 8 input paper feeders (6 standard) delivering a capacity of over 14,000 sheets (4,150 standard). The press runs at 150 ipm consistently on all media types.

Morrone notes that productivity is a key are of focus for Kyocera, “We launched the press with a projected duty cycle of 1 million letter pages per month. In practice, we are seeing customers run at twice that level with one customer running the press at 2.9 million images in a single month. Our average service performance of over 96 percent uptime contributes to that productivity.”

The TASKalfa is more than you think

Kyocera has bundled a number of high-end features into their entry-level press with the goal of maximizing up-time and simplifying maintenance:

- Most maintenance, including profile adjustments (ink management), curl adjustment, and front-end timing can be performed by the operator (supported by a robust, embedded paper catalog of recommended paper profiles.)

- Automated printhead maintenance technology eliminates dried ink and dust, extending the life of printheads and reducing the potential for “jet outs”

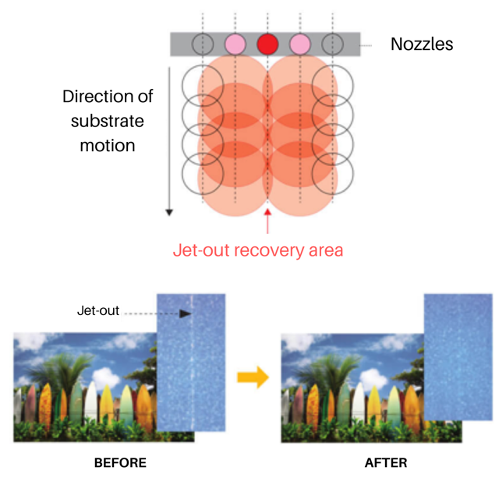

- In-line, on-the-fly, scanning and nozzle failure correction automatically detect and correct for jet-outs by compensating with surrounding nozzles (see below)

Figure 1. Kyocera Nozzle Compensation – Before and After Example

The press also automatically adjusts the distance between the printheads and the paper transport based on media thickness. This has the dual benefit of protecting heads from media strikes and controlling the ink throw distance for consistent print quality on varying media thicknesses.

As noted, the press comes pre-loaded with a media catalog and related profiles, but it also includes a software utility for ink estimation and related cost calculations. This can support more accurate cost estimating when done in advance of a bid or enable a profile to be adjusted to reduce ink consumption to the minimum level to achieve the necessary job performance appropriate to a particular cost estimate. Customers can create new profiles, including multiple profiles for the same media to reflect different levels of ink usage.

Another area, often overlooked in entry level systems, where Kyocera has added value, is data security. While additional access ports can be important for enabling connectivity, unused ports are often overlooked providing a path for hackers to exploit. Kyocera has built in protection by automatically closing any unused network or USB ports.

It all comes together

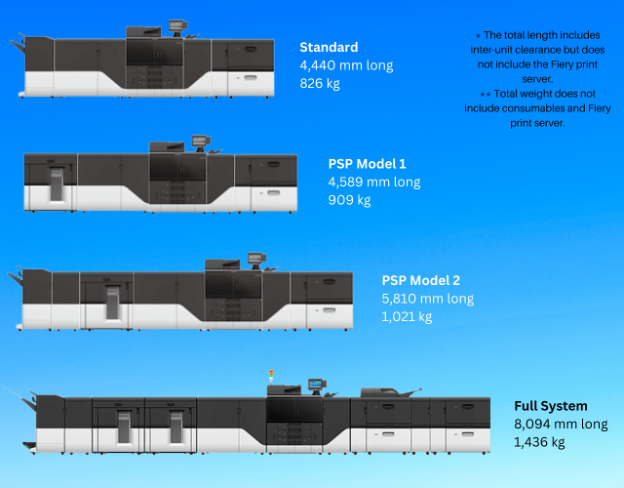

The TASKAlfa Pro 15000c is highly configurable and the many add-ons to the quality foundation of Kyocera printheads and inks create a highly productive package in a compact footprint.

Figure 2. Examples of Kyocera TASKAlfa 15000c configurations

The press runs on standard 100 Volt power simplifying installation and reducing energy consumption. The combination of price, productivity and print quality have led to the placement of over 370 presses world-wide with over 200 in the US alone. Fred Morrone says, “When we sell a press, they stick.” This claim is backed up by total worldwide page volume on the press approaching 1 billion images, with over half a billion images in the US, since the press was officially launched 3years ago, despite the impact of the pandemic on overall print volumes. “Our success is based on our customer’s success,” says Morrone. “When the press stays up and running, everyone wins.”

Comments

Hi Elizabeth

I think in your recent newsletter, you meant to say uncoated re G7 rather then coated?

Thanks Paul. So used to talking about G7 in a graphic arts context!