Gaining momentum

Finally, inkjet is gaining momentum in the flexible packaging market. Although flexible packaging is a huge market, the challenges are also big. UV inks are undesirable for food packaging, a major area for flexible packaging. For aqueous inks, being able to print with water on plastics is challenging. Additionally, the print technology needs to connect well to the subsequent finishing steps in laminating and pouch-making. Finally, offering white is important, while a large gamut can be desirable as well.

The leading digital print technology so far is electrophotography. HP with the Indigo Press 20000 and 25k has by far the biggest number of installations and upped their offerings in 2023 with the 200k. Also, Xeikon offers models for flexible packaging and with the recently launched Titon toner for paper-based flexible packaging. EP presses are slow in comparison with a web speed of 31 m/min for the HP Indigo 25k or 40 m/min for the 200k in four-color mode. Using white, especially in multiple hits, or other extra colours does reduce the speed.

Several inkjet presses have been announced in recent years, all based on aqueous inkjet, but commercialisation has been slow. Achieving high-volume production capabilities for demanding customers proved to be challenging and vendors took some time to hone the presses until making them available.

There are two tiers of inkjet models available so far. The high-end inkjet presses are designed for multi-shift, high-volume operations – to take on shorter run jobs, flexo presses are struggling to produce efficiently. In quality, substrates and by offering white they can easily slot in and complement analogue presses in established flex pack plants. Prices are high, however, in multi-million dollar or Euro ranges.

Entry-level models exist as well. They rather offer an opportunity for start-up companies to move into flex pack or for other printing companies, e.g., online printers, to offer low-volume prints. A small footprint and ease of use would allow an installation in almost any environment as well. They have a low investment point (low six-figure range) but have a limited substrate range, low productivity, and don’t offer white ink.

The overview below is based on models available or expected to become available soon. Flexible packaging materials are quite varied; therefore, we did not get into substrate details. It will be necessary to test desired materials on printability and quality. Also testing the quality after converting and packing processes is advisable.

Featured Flexible Packaging inkjet presses

Fujifilm Jet Press FP790

Fujifilm aimed for flexible packaging with UV-inkjet with the Eucon 540WV several years ago but markets outside of Japan were waiting for aqueous inkjet. Consequently, Fujifilm announced the Jet Press FP790 in 2021. The press also got wider (790 mm web width or 31”) and includes a double white. The press runs at 50 m/min in full 1,200 x 1,200 dpi resolution.

The FP790 is designed to fit into mainstream production and being compatible with existing production processes. With partners, Fujifilm also built an eco-system around the press to optimise productivity. In summer 2023 the first installations in Japan and in the UK were made. At an open house at the UK site in February 2024 the press was shown in production with customer jobs being produced since autumn last year. The event also marked the official launch and the press is generally available now. It will be shown at drupa and additional sites are expected to be announced soon.

Miyakoshi MJP30AXF

The MJP30AXF has been announced in 2020, as Miyakoshi’s first water-based press for flexible packaging printing. Unlike its predecessor, the MJP30AXF is using aqueous inkjet. As the Fujifilm FP790 is built on the same web transport, both devices share the main specifications, however in many details the presses are going to differ.

The MJP30AXF has a print width of 750mm (30”), a web width of 790 mm and is capable of running at 50 m/min (164 ft/min). The press uses 1,200dpi heads from Kyocera for CMYK and double white printing. A first installation took place at Kanaoka Packaging, a leading Japanese flexible packaging printer, in 2022. The company so far used conventional presses only, but built a new site to focus on digital printing now. Miyakoshi plans to sell the press also outside of the home market in Japan.

MTEX NS Flexpack 6

MTEX New Solutions launched the NS Flexpack 6 at LabelExpo 24 in Brussels. MTEX is an equipment manufacturer based in Portugal, known also for producing OEM equipment marketed by other companies. The NS Flexpack 6 is an entry-level flexible packaging printer using aqueous inks and HP inkjet heads. With an 800 mm roll width, a 642 mm print width is possible, although a wider model with a 1070 mm print width is about to launch as well. The speed is modest with 9 m/min at full 1,200 x 1,200 dpi resolution or 18 m/min at half resolution.

As an entry solution, the NS Flexpack has an investment of around €200k. The very small footprint is owed to leaving out a drier. As a consequence, the press requires inkjet-optimised media. A cold laminator is integrated and larger roll handling and a slitter are optional. At LabelExpo, MTEX targeted a release in Q4 2023. More recently, the company did not respond to several attempts to provide more details on the roll-out, so you have to try your luck at a trade show to find out whether it is shipping already.

Paper Converting Machine Company ION

Paper Converting Machine Company (PCMC) is part of the Barry Wehmiller group, which is, although less known, the largest company in paper processing and finishing. A reason for the probably unfamiliar name is that the Barry Wehmiller business groups typically stem from acquired companies that continue to trade under their traditional name. For the ION press, five companies pooled their knowledge, including the part of PCMC that builds the Fusion flexo presses, Winkler + Dünnebier, the manufacturer of mail solutions, and Hudons Sharp, the maker of pouch-making lines.

The ION has been designed as a hybrid inkjet-flexo press. Flexo stations can be added before and after the inkjet unit. The inkjet hardware is sourced from Memjet. Its DuraLink high-volume technology prints in CMYK with a resolution of up to 1580 x 1600 dpi. A primer is used for media flexibility. In inkjet mode a speed of up to 123 m/min (400 fpm) can be reached, albeit at reduced resolution. In analog mode, the press reaches 1000 fpm. As the Memjet unit prints process colours only, varnishes, spot, and specialty colours can be added with the flexo units. The press is available in three widths, from 915 mm (36”) to 1320mm (52”) web width. A first site is already using the press commercially and the ION is available for orders.

A few other devices offer adding a flexo unit, while the ION has been designed from the ground up to be a hybrid press, hence targeting a higher volume market. As a result of the design, static portions can be printed with lower-priced flexo inks, while only the variable or customised image portions require inkjet. However, changing flexo forms results in downtime and costs for the flexo plates, making the press less suitable for very short runs.

Rigoli MVZ 1000

Another entry level solution is marketed by Italian manufacturer Rigoli s.r.l. with the MVZ 1000. Rigoli manufactures a range of wide format printers and ancillary equipment. Accordingly, the MVZ 1000 is based on a 1m / 42” wide format printer using Memjet inkjet technology, which was adjusted by Rigoli for flexible packaging. As commonly found with Memjet technology, the press has several speed settings with the max speed of 18 m/min using 800 x 1,600 dpi or 9 m/min at full resolution. As typical for Memjet, CMYK print is offered, which includes a double K-channel. The inks are dye-based and safe for indirect food contact.

The MVZ1000 is available in Europe and there are several installations in operation.

Screen Truepress PAC830F

Screen has a long track record in continuous-feed inkjet printers. In 2021 the company announced its first venture into flexible packaging inkjet with the Truepress PAC830F. Featuring a width of 830 mm and a speed of 75 m/min, the Truepress PAC830F is a flexible packaging printer with an industrial level of productivity and is intended to complement flexo installations for lower run lengths.

The press is using water-based inks for CMYK and white, with a new technology that promises opaque white in one hit. The inks are food compliant.

The press is in the final stages of development. In October 2023 a partnership with flexible packaging printing company Chiyoda Gravure in Japan was announced and a first press was installed.

Screen Truepress PAC520P

Announced in September 2022 Screen added a second model for the flexible packaging market. The 520P is targeted at paper-based flexible packaging, however. The press is based on the tried & tested Truepress NX platform, but it is a single engine device and has been modified to be used in flexible packaging. It features specially developed inks that are food compliant. So far only CMYK is available but plans for an extended gamut exist. Lacking white ink is not an issue for fibre-based substrates.

Truepress PAC520P is expected to be released just before drupa 2024, around April or May. The machine is available for tests and demos at Screen’s demo centre in Amsterdam.

Uteco/Kodak Sapphire EVO M

The EVO M was developed by the Uteco Group in partnership with Kodak and utilizes Kodak’s heads and water-based inks. The system is sold by Uteco. The Sapphire Presses are designed for printing on flexible film and paper substrates. The press can also produce promotional materials (envelopes, signage), industrial packaging, and home décor. Sapphire EVO M is targeted at monthly production volumes from 300K m² to 600K m² per month, for 1 shift operation in 5 days. Also, hybrid printing configurations are possible, deploying in-line printing with spot colours and OPV varnishes.

There are about three early user installations in operation. The Sapphire EVO M is in controlled sales/service for US, Eastern/Western Europe geographies.

Uteco/Kodak Sapphire EVO W

Another result of the Uteco/ Kodak partnership is the Evo W, which has been announced in 2020. The “W” refers to “wide” since this press has a 1260 mm (49”) print width and 1350 mm web width. It is the first press to be powered by Kodak ULTRASTREAM continuous inkjet technology.

The Sapphire EVO W is targeted at monthly production over 500K m² to 1.2 million m² per month, for 1 shift, 5 days. Given speed and width, the EVO W is the most productive line proposed so far. Options are a primer unit, white preprint and varnishing unit. Sapphire EVO W is first adopter sales stage for US, Eastern/Western Europe. There is one beta installation in operation.

Table 1. Inkjet presses for flexible packaging print.

|

Number of colours in inkjet |

Speed |

Max web width |

Substrates |

|

|

Fujifilm Jet Press FP790 |

CMYK + 2 white |

50 m/min at 1,200 x 1,200 dpi |

790 mm |

PET, BOPP, Paper |

|

Miyakoshi MJP30AXF |

CMYK + double white |

50 m/min at 1,200 x 1,200 dpi |

790 mm |

|

|

MTEX NS6 |

CMYK |

18 m/min at 600 x 1,200 dpi |

800 mm |

Inkjet optimised PP, PET and paper |

|

PCMC |

CMYK |

123 m/min / 400 fpm at 790 x 1600 dpi |

915/1066/1320 mm |

PET, BOPP, paper-based |

|

Rigoli MVZ 1000 |

CMYK |

up to 18 m/min |

1067 mm |

Inkjet optimised media |

|

Screen Truepress PAC830F |

CMYK + white |

Up to 75 m/min |

830 mm |

PET, BOPP |

|

Screen Truepress PAC520P |

CMYK |

80 m/min or 120 m/min up to 600 x 900 |

520 mm |

Paper-based |

|

Uteco/Kodak Sapphire EVO M |

CMYK |

up to 200 m/min |

650 mm |

PP, BOPP, PE, PET, paper |

|

Uteco/Kodak Sapphire EVO W |

CMYK |

up to 150 m/min |

1,350 mm |

PP, BOPP, PE, PET, paper |

Other presses on the horizon

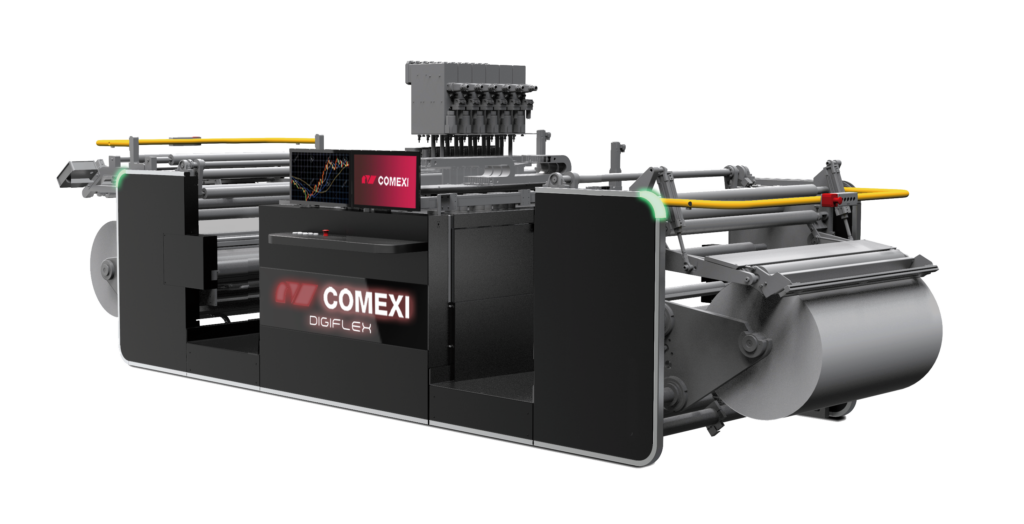

Comexi D4 and DIGIFLEX

Spanish flexo press manufacturer Comexi announced the D4 at virtual drupa 2021, as a water-based inkjet digital press configurable with up to eight (CMYK+OGVW) colours. The print width is 866 mm and the press was announced to print at 75m/min at 1200 x 1200 dpi and 150m/min at 1200 x 600 dpi. The D4 uses Fujifilm Samba printheads and Comexi works with Sun Chemical on inks for the new press. Comexi states that “the availability is confidential”, which probably means you have to sign an NDA to find out if it is selling.

Already available is the DIGIFLEX, an offline variable data imprinting solution to codes, numbers, and data to pre-printed flexible packaging webs. It consists of an unwind and rewind and a set of printheads in between. Up to 12 monochrome inkjet heads can be used with a 40.6 mm (16”) width each, across a web width of 1320 mm. UV inks are used and a speed up to 220 m/min is reached with a resolution of up to 1,200 dpi. The DIGIFLEX is already on sale.

Landa W10

Announced at drupa 2016 the Landa W10 has been in the making for some time. Previewed specs are a 100 m/min web speed and 1,050 mm web width. Consistent with other Landa presses it uses an intermediary (blanket) on which the inks are jetted. The ink is (almost) dried on the blanket and transferred as a tacky film. This avoids having to dry the ink directly on the substrate, which can overcome wetting problems or heat issues. The downside is that an extra process step and consumable (blanket) is added, and some images need to be stitched. The availability of the press has been moved several times and there is no statement on the planned available currently. Given Landa’s quirky launch habits, we might see it at drupa 2024 or sometime in a (distant) future.

Yet more options

There are some low-volume inkjet printers based on Memjet technology that are suitable for smaller packs but not as an extension for existing flexo presses. They also feature a narrow web width. Product available are from Afinia Label the Afinia FP-230, launched in 2020, the AstroNova with the T2-L,and from ArrowJet the Aqua 330R. In 2022 the i-Jet2800 from Inkjet Solutions was added to the market. From V-shapes even a complete print & pack solution exists. The concept combines a Memjet DuraFlex print engine with a single-portion sachet forming line for small sachet sizes from 40 x 50 mm up to 100 x 100 mm and a filling range from 0.2 to 30 ml.

Alternatively, if coding, marking, and small personalisation are what you are aiming for, a number of inkjet bars exist that can be mounted on presses or finishing equipment. Typically, they are monochrome and not destined for high-quality graphics. UV or solvent inks might be necessary, as typically no complex pretreatment or drying can be fitted.

This Shopping Guide is intended to give a high-level overview of flexible packaging presses available or announced. More details on the products can be found in the Inkjet Insight Device Finder and in previous coverage of some models. Stay tuned for more shopping guides from Inkjet Insight. Stay tuned for additional packaging related Shopping Guides and make sure to register for our March 12 webinar on Inkjet Innovations in the Packaging Industry.