Dr. Kai Bär of Adphos Group is a leading expert on Near Infrared Drying, or NIR and inkjet. I had the opportunity to talk to him recently about the role that drying technology plays in achieving quality output with production inkjet.

Many drying technologies can be very punishing on the substrate resulting in mottle, cockle and curl. Finding the right drying option is particularly important as inkjet moves into application segments requiring heavy ink coverage and fine image quality. Some areas that put a focus on finding the right drying solution include printing on very porous (untreated) papers and, the opposite end of the scale, offset coated stocks. Printing on very light/thin stocks is also a an area where drying can expand the range of media options.

After you watch the video – scroll down to see more images.

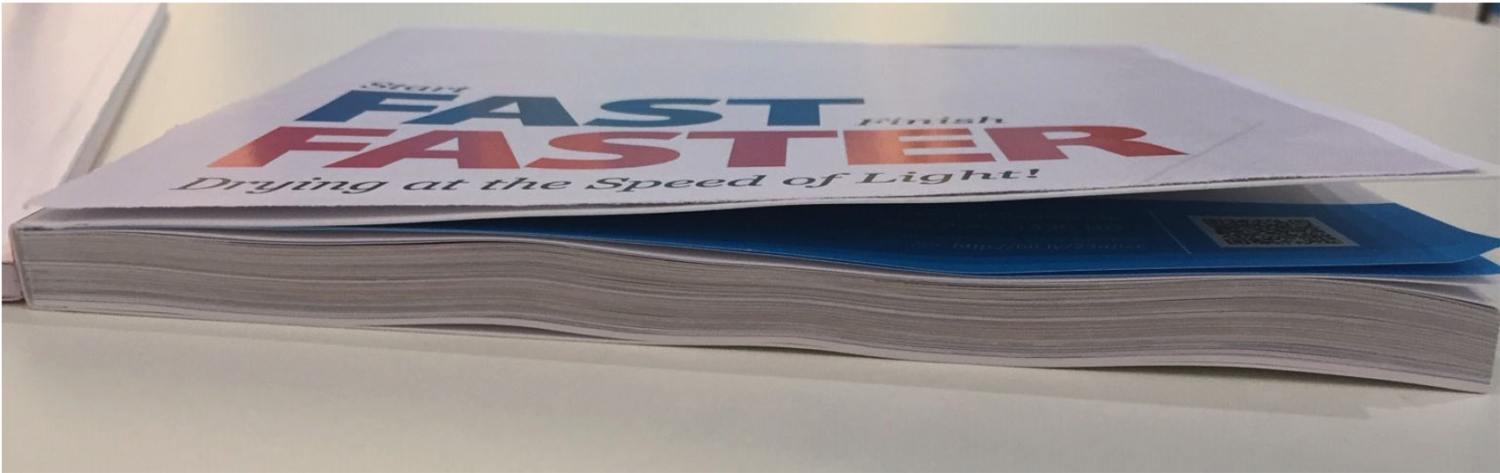

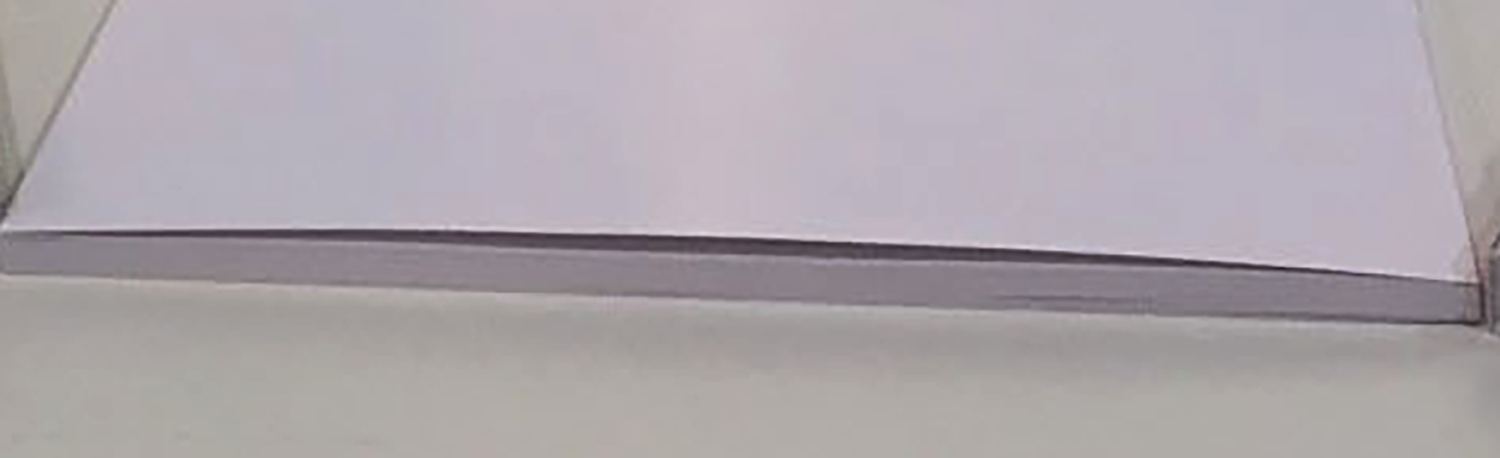

The images below show the difference that NIR drying can make in keeping printed pages flat.

Inkjet Book – Hot Air Drying Technology – Shows Significant Waviness/Curl

Inkjet Book dried using Near Infrared (NIR) with No Waviness/Curl

It’s important to note that NIR solutions use dramatically less power for drying and can be a factor in calculating Total Cost of Ownership(TCO) NIR solutions are available standard in the Screen Truepress Jet 520HD and as a custom option from several other inkjet OEMs. If you are working with an inkjet integrator to create a bespoke solution, consider Adphos Group for the drying solution.

Comments

Dr. Kai Bär of Adphos Group, what a treat, to listen to his commentary. Great interview. I’ve noticed that Screen seems to be partnering with vendors to enhance their Inkjet printer engines. Here again they’ve made their drying technology a standard feature on the Truepress Jet 520 HD. They also choose a stand-alone web cleaning device which cleans paper, eliminates static and removes chads and paper dust prior to entering the printer.

It’s good to know about drying and how it reacts with various substrates. The perfect interview.