Often inkjet users are on the hunt for the smallest possible drop however sometimes a large size is what is needed – typically not in graphic arts printing but in many other markets where inkjet could be used as well. Powerdrop from Archipelago Technology is a new process to create large droplets and the technology is now starting to be commercialised.

Archipelago Technology is a small technology company based in Cambridge, UK and was founded in 2012. CEO Guy Newcombe has a long experience in inkjet as CTO at Tonejet and with other inkjet technology companies.

The process

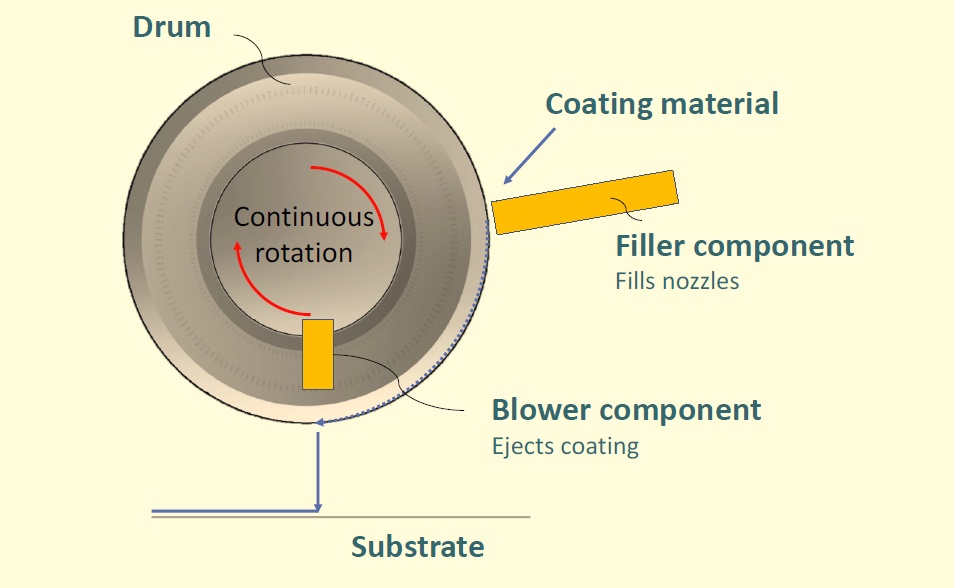

The Powerdrop process itself is relatively simple compared to other inkjet technologies. This is a great boon for industrial applications where reliability is paramount.

The foundation of the process is a hollow metal cylinder with a great number of tiny holes. The holes have a diameter of half a millimetre and are set apart by about one to two mm. According to research and tests by Archipelago Technologies, these measures provide the best results across a wide range of parameters. The company standardised on these dimensions so far – although theoretically the sizes can be varied.

A filler component including an ink dispenser and a sort of squeegee is used to dispense liquid onto the drum and to push it into the holes. It needs to be taken care that the holes are not filled by more than half, as not to have liquid leak to the inner side of the cylinder. The amount of liquid in the holes is essentially determined by the amount of ink dispensed on the drum and can be changed on the fly.

Jetting the droplets is simply achieved by a blower component, similar to an air knife, inside the cylinder. The air jets the liquid onto the substrate. By switching the air on and off simple patterns can be generated, even across the web direction when a sectioned air knife is being used. The process does not lend itself to imaging by pixel or jetting single droplets, instead only larger, continuous areas are possible. In this respect, Powerdrop is more of an analogue technology as it does not allow addressing single pixels.

Schematic drawing of Powerdrop process

A speed of the drum of up to 120 m/min can be achieved. The surface speed can be even faster as this is a non-contact process – it simply would result in a lower amount of liquid transferred. Drop velocity is about 2 m/sec, allowing for sufficient jetting distances.

UV and aqueous liquids are used already today, although the process is not limited to any solvent/liquid type. Even molten substances can be jetted as the drum can be heated, up to 160°C. The process also allows for very viscous fluids, which cannot be jetted otherwise. Additionally, particle sizes up to 100µ are possible, thanks to the large diameter holes.

Drum widths from a few centimetres to two metre are envisaged, although theoretically, the width can be even wider. As an alternative, drums can be stitched for any custom width.

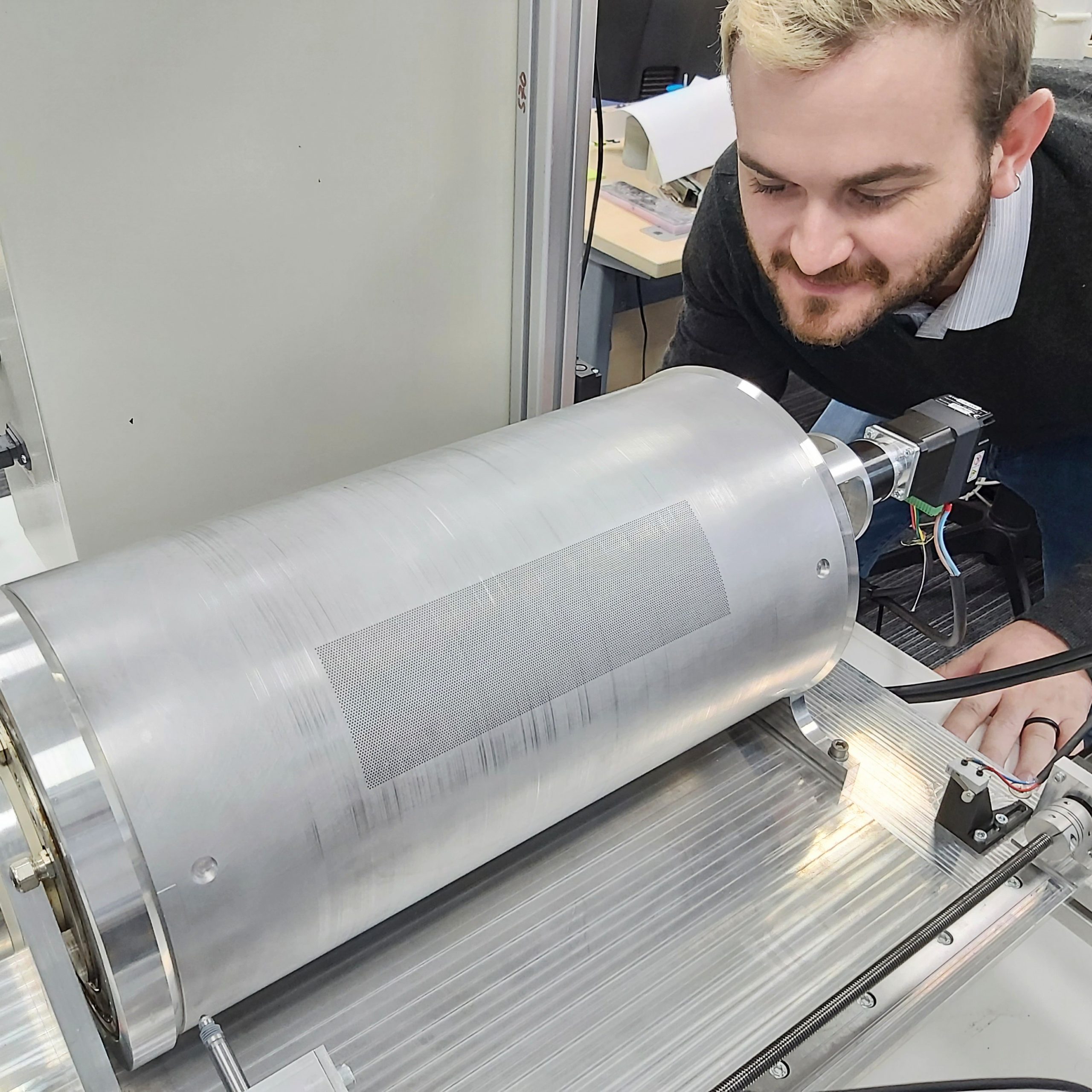

While most applications will need some fine-tuning and adapted sizes, a 200mm-wide proofing unit is available today to test the process. It has a coating speed of up to 120m/min with a viscosity range typically between 100-1,000mPas.

Powerdrop drum in testing

Applications

The Powerdrop technology can jet a wide range of fluids with a defined amount and position onto a surface without contact. Uneven or delicate surfaces are possible as well. Those properties make the technology interesting for several markets. Especially being able to use viscous fluids and high transfer amounts set the technology apart from inkjet in general. Archipelago is currently working on four application areas:

- Furniture and industrial coating

- Paper coating for sustainable packaging

- Liquid labelling

- Agricultural coating

In furniture and industrial coating Powerdrop can be used to apply paint or varnish to a material surface. In traditional spray coating, about 50% of the varnish is lost in the air. This is not only a waste of material, it is also an environmental hazard and requires frequent cleaning of equipment. With Powerdrop more than 97% of the liquid is used for the purpose. The process is also suitable for delicate surfaces and a wide range of fluids, areas where roller coating fails. Patterns are possible as well, when keeping areas unvarnished is required.

Coating paper is based on the megatrend of brands moving away from plastics to fibre-based packaging. Fibre-based materials have to be coated however to be fit for the requirements in packaging. This includes barrier functions or applying adhesives. Archipelago is working with world-leading packaging converters to prepare papers for packaging purposes.

Liquid labelling refers to applying a white box or stripe on a packaging, to have other information imprinted. Powerdrop can deliver an opaque white layer, also on delicate surfaces. Required widths would be small with only a few centimetre imaging width.

Not immediately obvious are applications in what is called agricultural coating, which refers to dispensing substances onto a plot when growing crops. Crops are typically sprayed six times a year, which leads to a massive waste of chemicals as portions evaporate into the air or are applied to spaces that do not require treatment. With Powerdrop substances can be deposited much more sparingly and specifically to the areas that need treatment. Two metre wide modules would be used to achieve sufficient productivity.

The next steps

Although the process itself is simple, Archipelago technologies spent considerable time to optimise the process and filed several patents in developing the process. Some adaptation and tests are needed for every application, therefore the company is focussing on a limited number of segments as mentioned above, although more applications are conceivable. Archipelago does work with partner companies in each area as well to commercialise the products.

There are first installations in furniture coating and paper coating. Liquid labelling installations will follow soon. Agricultural applications are a bit further out – however, this is the market where potentially the largest number of units can be sold – Newcombe estimates that 100.000s of units could be required. The other markets are smaller with several thousand to several ten thousand potential installations.

The price of an installation will range from €10k to €100k, depending on size and application specifics. This is higher than a spray coating set-up, but much lower than a typical inkjet installation.

Powerdrop does not play in the graphic arts or packaging printing areas so far, although there would be cases where depositing viscous, high particle load or high-volumes inks in a certain pattern is needed. Possible applications could be flood or section varnishing with clear or metallic varnishes. Even functional surfaces would be achievable. A use in priming could make sense when certain areas need to be left out. Also, laying down a high opacity white could be an application. While the first applications are already set, Powerdrop could pop up in the future as a complement to graphic and packaging printing as well.

Comments

Its like a pressure educed anilox roll with dr blade applied ink. will be interesting to see this one applied.

Yes, there are some similarities. But Powerdrop allows emptying (jetting) these liquids without further machinery – even with the possibility to create patterns.