Services to Improve Your Inkjet Journey

You are embarking on the journey to acquire an inkjet press and want to maximize your return on investment. You’ve seen the presses at a trade show, attended some special events hosted by the equipment manufacturers, been wined and dined by their executives, attended meetings at OEM demo centers, and maybe even tested papers and sample jobs. It’s a serious purchase that requires a serious investment of time by you and the manufacturers.

The good news is that the equipment manufacturers are not only competing with each other for your business, they are fairly vested in your long-run success. They want to ensure that you:

- Are financially able to acquire their equipment

- Will be successful and less likely to default on your agreements

- Can grow your volume and deliver a profitable supplies and service annuity stream

- Remain a loyal customer and purchase more equipment over time

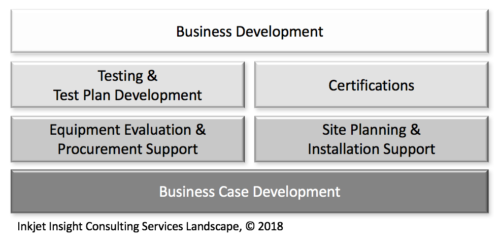

Manufacturers have learned that it’s in their best interest to offer a range of services to help you with your buying journey. Most OEMs have invested in teams to offer pre-sales, implementation and post-implementation services. Some of these services may be free, or discounted through the OEM making it worth your while to consider a range of services when evaluating inkjet.

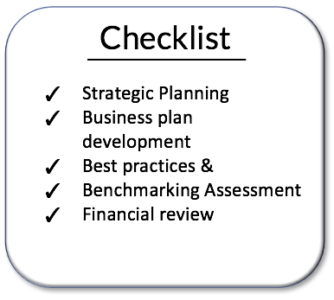

Business Case Development

Too often, purchasing equipment is followed, rather than preceded, by developing the business case for the purchase. This has been a perennial practice in the printing industry and often leads to bad decisions that can have a negative impact on the business. Inkjet Insight encourages print providers to make the case by building a sound strategic business plan that accounts for current business and sources for projected volume growth including customer segments, technology transfer, and applications. This is often required by equipment manufacturers as they are doing their due diligence to determine your risk profile. You should understand the productivity of your operation, how you compare to the industry and the benefits you seek to achieve with adding new equipment. We also recommend a thorough analysis of your financials to assess how an acquisition may impact your business and to ensure that you have provided the information that will allow you to get the most favorable financing rates.

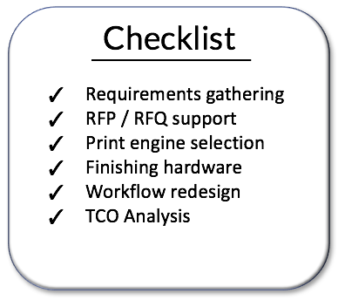

Equipment Evaluation and Procurement Support

To some, the evaluation process is the fun part with lots of activity and attention from technology vendors courting your business. It’s also critical that the process be structured so that it is clear that any wining and dining is not the catalyst for your decision. We recommend conducting a detailed requirements assessment. This will help you hone your criteria for the type of printing device you really need and enable creativity while avoiding paying for things you don’t need. Requirements then form the base for the RFP/RFQ process. This is an area where the OEM can’t really help you if you want to ensure that the analysis is unbiased and considers all potential suppliers. This is where an independent expert can support your efforts with evaluation support and negotiation skills. Don’t forget that finishing hardware and workflow may be the key to whether you are successful or fail. This means that you will want to strike a balance between gathering information from OEMs on their recommended partners and soliciting independent advice on “best-in-class” solutions. The technology vendors do a great job offering a range of solutions for a wide variety of applications, but that doesn’t mean they offer all of the options available. A third set of eyes can help make the selection a lot easier and create a win for your procurement process.

Site Planning & Install

Even assuming that you took into account the site and environmental considerations before deciding which device you selected – if this is your first inkjet purchase and you didn’t get an outside perspective, there may be some things you missed. These are considerations that you want to be able to hold your OEM accountable for if you have problems – but, you can’t do that if you didn’t take the time to work with them up front. Spend time understanding the requirements, costs to modify your plant, and all electrical, air quality, safety and other environmental considerations that may come into play as you work with new inks, new papers and potentially shift from roll to sheet or vice versa.

Typical services that support a successful implementation include specialists to help design the site, equipment layout, and the all-important physical workflow. You might also uncover space or workflow savings that help you make your business case – particularly if you are able to eliminate preprinted stocks in favor of white paper. Site modifications may need to be planned and engineered such as humidification systems, HVAC systems or other advanced ventilation. The installation is generally the responsibility of the technology vendor, but it can be helpful to have a “buyer’s representative” to monitor the installation and report on unforeseen issues that may arise. Once installed, you will need to ensure your machine is running up to spec. This is also where the “buyer’s representative” can participate in the process. Finally, you will need to train your team to ensure you get the most out of your press. You will find great value in vendor supplied training, but we also recommend working with consultants who have worked on numerous installations and can share best practices related to your application segments or paper and ink combination.

Once your press is installed, it’s imperative to ramp up your activities to drive customer acceptance and revenue. The second part of this series will discuss testing, certifications, and business development. There are services from the OEM and independent sources that can help you reach your destination more quickly and make it a more enjoyable trip. I’ll look forward to sharing more ideas next time.

Meanwhile, please reach out to our team if you want to learn about consulting services from Inkjet Insight.