Bobst has been widely in the news recently when the Digital Master Series was launched. While it is an interesting product by itself it gives a valuable insight into Bobst’s product and technology strategy.

Moving into digital

Bobst is an established supplier to the printing and converting market with a long tradition. As many traditional companies Bobst was a relatively latecomer to digital print – which is understandable as in the core segments Bobst is active in, digital printing played almost no role for a long time.

The first foray was a cooperation announced in 2013 with Kodak, which led to the announcement of an inkjet press for corrugated in 2015 – the first of its kind in high-volume inkjet printing on corrugated. The press never made it beyond beta installations and as usual with a completely new generation of devices it had, at least some, teething problems. There were technical and business model reasons the press did not take off, however it seems that the core reason for terminating the project was Bobst not being in control of the whole development.

This changed to some extent in 2017 with the founding of Mouvent. Mouvent started as a joint venture between Bobst and Radex, the latter essentially comprised of the former managers of inkjet component supplier Graph-Tech. While formally independent, Mouvent was still described as the digital print competence centre of Bobst. Keeping the company independent surely helped to preserve a start-up culture in a fast moving market and it would have permitted Bobst to exit swiftly if things would go downhill. The most prominent development of Mouvent was the inkjet cluster technology, which allows for an integrated, yet modular approach for inkjet presses.

In 2019 the Mouvent LB701UV and 702UV label printer were launched. In a busy marketplace for UV inkjet label printers the devices gained a good foothold. Without the pandemic the products would have surely been even more widespread.

Apparently Mouvent proved to be successful enough that in December 2020 the remaining shares of Mouvent were acquired by Bobst, making Mouvent a fully owned subsidy with a much tighter integration into Bobst. By then Mouvent’s cluster technology has been deployed in the Mouvent LB701-UV, LB702-UV and the Bobst Master DM5 presses. More than 20 presses have been sold in Europe and the US during 2020. Not surprisingly the new Digital Master Series is using Mouvent’s know-how and cluster technology as well.

The Digital Master Series

As other articles already depict the press in detail, I would like to highlight some features of the Digital Master Series and their implications.

First, the Digital Master is a hybrid press, which describes combining a digital imaging unit with traditional substrate transport, analogue pre- and post-print units and in-line finishing processes – or at least having the option for those. Hybrid label presses are offered by a range of vendors and cater for the high end of the digital print label market where label printers are accustomed to complex products and high volumes.

The Digital Master Series comes in two models. The Digital Master 340 is a narrow-web 340mm (13.5”) press while the 510 is a mid-web press with a 510mm (20”) print width. They are built on Bobst’s modular and upgradable M5 flexo platform in combination with their Mouvent Cluster inkjet technology. Imaging resolution is 1,200 x 1,200 dpi with up to six colours plus white. Print speed is up to 100 m/min and without inkjet printing up to 160 m/min would be possible. All finishing modules from the M5 flexo platforms can be integrated, even additional modules are possible with some adaptation.

This modularity sets the Digital Master Series apart from the Master DM5, launched only 2 years before. The specs of both models are surprisingly similar. On the face value it would not have made much sense to replace the DM5 already. Despite Covid restrictions the DM5 sold well with about 15 installations so far. The true driver for a new generation runs deeper. The Digital Master Series has been redesigned from ground up to integrate a digital imaging into a fully modular, modern press and likewise have digital imaging at the centre of the press architecture. A sign of the much better integration is that the DM5 essentially consisted of two platforms: digital and analogue, with two different control systems and operator panels.

Another example of a closer integration of all components into the press and into the wider Bobst infrastructure is the Accucheck inline inspection system – now being standard on the Digital Master Series. Accucheck is already standard for folding carton presses but new to label print. The system allows inline control of print quality, including full inspection. As the system can check for faults in varnishing and finishing as well, a tight integration into the full press line is necessary. It is also a prerequisite for a highly automated production and instant error compensation.

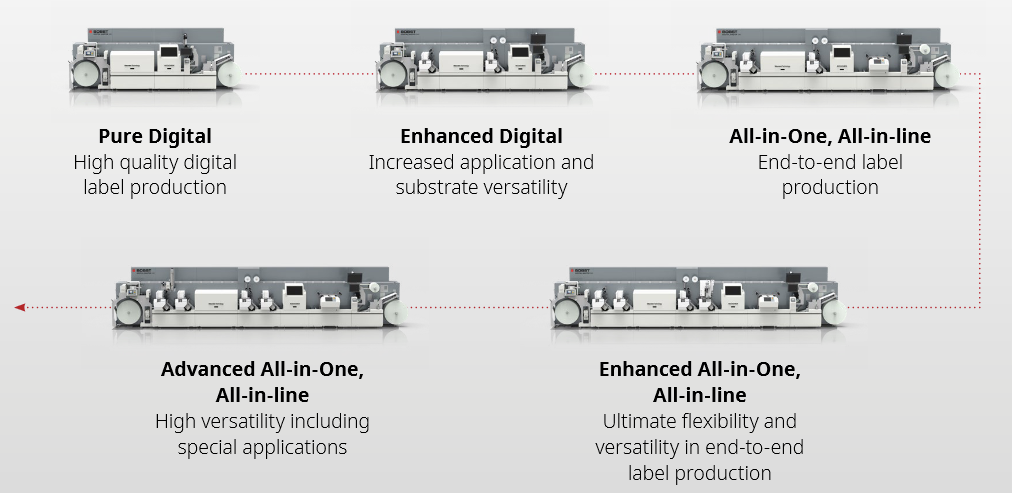

Examples of Digital Master configurations

Another feature setting the Digital Master Series apart is the basic or pure digital configuration, in which it is essentially making the Mouvent 702-UV obsolete. The 702-UV has essentially the same specs as the Digital Master 340 in a digital only configuration. Rather than having two very similar devices in the portfolio it will make more sense to streamline the portfolio. The LB701-UV as very narrow web (190mm) and lower speed (70 m/min) device remains as a lower priced, entry device for printers getting started in digital.

Bobst is certainly not running out of development opportunities for label presses. It seems that the development of aqueous inks did take a back seat lately. Announced a few years ago the inks are still stuck in testing. While aqueous inks have drawbacks (more elaborate drying systems) they would open opportunities with customers shying away from UV inks, which would enlarge the application range. Another piece conspicuously absent in a new label line so far is a laser die cutter. Here Bobst is aiming for an internally developed solution as well, that would integrate as tightly into the complete press line as the other modules.

The (much) wider scope

Like many industry voices, Bobst affirms that many print technologies will coexist in the future in label printing (and other applications). Inkjet is growing much faster than other technologies, however. Combining technologies is standard for Bobst, as all label presses and finishing units are modular. Accordingly, all presses shipped are configured to order and there is hardly any standard configuration.

Bobst is a large manufacturer of press and converting equipment. The company has the resources to internally develop a wide range of technologies and knows about the benefits of a close integration of all process steps. Even with digital imaging lacking for some time Bobst spend considerable know-how in digitising processes and optimising the full print and converting process.

Based in a high labour cost country Bobst is naturally focusing on high performance rather than commodity products and plans to lead in innovation. It might have been lost somewhat in the product launch news that Bobst is aiming for highly automated production or lights-out-factory concepts. While the concept has been around for a while, not many voiced this as an aim in the print industry recently. While it is an ambitious objective, it aims at the core issues in print: lowering cost, increased production reliability and combatting labour shortages. No doubt integrated press concepts, in-line quality control and digital imaging will play an important role here. Especially inkjet imaging technology will see a wider adoption in the products from Bobst.