Inkjet & Sustainability

We hear so much about how inkjet implementation is being driven by sustainability considerations. Kelly Lawrence previously offered a really good discussion of this with a packaging focus and a business and marketing perspective. But what are the technological differences and potential benefits of one formulation versus another when viewed from a sustainability direction? In this introductory, more technical, look at the topic, we challenge some oversimplifications often used in the market.

Clarifying a Buzzword

The best way to start is usually to try and find the most common definition and Wikipedia is often a good place to start. Getting a definition of sustainability from Wikipedia was a learning experience and a half! One of the major takeaways is that we shall be narrowing the focus to the concept of environmental sustainability. For a working definition we shall use “meeting the resource and services needs of current and future generations without compromising the health of the ecosystems that provide them.” For the purpose of this article whenever I say sustainability, I really mean specifically environmental sustainability.

Fig 1: A common image portraying sustainability, but what lies behind the greenwashing?

So, what does sustainability mean when it comes to inkjet printing? The most obvious consideration is that any consumables involved, such the ink, should be made from materials that are derived from natural sources. The other, is to minimise the material and energy resources being used to produce the final product (print) and often that comes down to calculating something like the carbon footprint. However, because that is a complicated mix of input we will focus on the energy requirements.

Superficial Assumptions

When I first started writing for Inkjet Insight, my first posts were about the difference between the major inkjet types being used in different applications, including water-based, UV and solvent-based. When compared superficially, these three ink technology platforms appear to be easily ranked using the following rationale:

- Worst = Solvent based because of the ‘evil’ volatile organic compounds (VOCs)

- Better = UV-cured because it (usually) does not contain VOCs

- Best = Water-based because water is green, right?

This simplistic reasoning has some validity, especially when it comes to the main carrier components, but it overlooks some important contributiona to the overall process of printing/converting. In particular it overlooks variations in the power required for drying, but first let’s pick apart some of the assumptions.

Materials

We shared the assumption above that water is green or eco-friendly. At the highest level of analysis it certainly can be. Once evaporated from the ink, water in its vapour form can be returned to the ecosystem and the same cannot be said for the majority of organic solvents when used at industrial scale. But manufacturers of ink use massive amounts of water and it is a key part of their sustainability policies to monitor and reduce it. See for example Sun Chemical’s latest report.

The often-overlooked issue is that a truly functioning aqueous inkjet ink is not just water and, in some industrial applications the amount of water can actually be pretty small. Thankfully, when printing to paper, there is typically still quite a good fraction of the formulation that is water, probably a minimum of 50% by weight.

For inkjet though, that water content is not just out of the tap, it has to be processed and purified (de-ionised) in order to formulated into an ink. This process is called reverse osmosis an requires resources in the form of filters and electricity. Even so, it is fair to say that producing deionized water is certainly a simpler and lower energy process than brewing and distilling ethanol from bio sources, for example. So, water still wins as the carrier.

The rest of an aqueous ink is a mixture of glycols, surfactants, pigments and biocides. Every single one of these materials is a product of the speciality chemical industry and likely derived from energy-intensive manufacturing and purification. Some can also be quite hazardous which is why any inks should always be disposed of responsibly.

When the ink is intended for coated papers, then the amount of binder resin is usually increased. The raw materials used for making those binders has quite a lot in common to UV cured inks. As a result, 5-10% of a functional water-based ink is plastic. However, this is still better than a typical UV ink where maybe 80% of the ink is made of cross-linkable monomers/oligomers made derived from petroleum chemistry.

Fig 2. Replacing petrochemical sources is a big factor in the future development of sustainable inks

In analog printing inks the trend is to move onto materials that are sourced more sustainably for example, by using a bioethanol as a solvent or a naturally sourced resin. Sun Chemical’s SunVista AquaGreen does the latter and is targeted at paper-based packaging, but the technology approach is not yet transferred into inkjet.

Leading suppliers are now also offering UV-curing materials with renewable carbon content, like Arkema’s Sarbio range. Unfortunately, the number of options is relatively limited and, since inkjet tends to rely on a sub-set of materials in the outset, it will be some time before that becomes an opportunity for inkjet formulators. However, It is all progress in the right direction.

Printing & Drying

The drying of an ink is one of the main uses of electricity in printing. In traditional analog print markets this, combined with the VOC argument, has led converter away from solvent to use more UV/EB curable inks, and the next step has been to push the use of UV-LED curing sources to decrease power consumption.

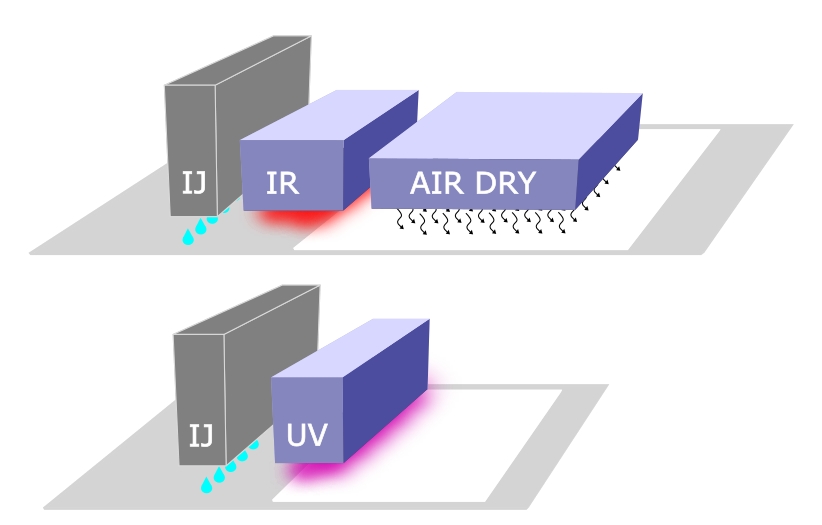

Fig 3: UV offers advantage over water-based in terms of the process simplicity.

An analogous shift has also been occurring in the wide-format graphics world throughout the last two decades, although smaller machines still use so-called eco-solvent inks. This name does not testify specifically to their sustainability credentials but is a reference to the fact they are less likely to give you a bad headache when used in mixed-use areas. It is still best-practice to use extract on any solvent printer!

For water-based inks, the biggest challenge for inkjet sustainability is that the low viscosity necessitates low solid content. In other words, you have to do more drying than with a flexo ink, for example, to deliver the same amount of colorant onto the paper/package. So, what looks like an advantage in terms of percentage of sustainable ingredients becomes an increased carbon footprint due to all the extra electricity needed to vaporise that water.

When we start adding higher boiling-point co-solvents (e.g. glycols) to control the latency effect in the printhead, then we need even higher power requirements, much longer drying systems with more airflow management, or some of both. Unfortunately, there is not much public data to use to demonstrate the true impact of AQ versus UV in true-life usage case examples. Anecdotally, the UV-LED curing lamp in the author’s lab uses much less power than the NIR system that successfully dries similar quantities of AQ inks at equivalent speeds. Add to that the fact that drying per colour is much more common in water-based for non-absorbing substrates, there is clearly an energy price to pay for the “cleaner” chemistry.

The Takeaway…

Defining an inkjet ink as sustainable is a complex balance of the materials used and the process applied to convert it within the printer. Just because it is water-based does not mean its overall impact on the environment is much less. Meanwhile, competing UV technologies continue to be developed and remain an option where regulatory requirements permit. Don’t take it for granted that your water-based printer is more sustainable – ask for details and then do your own analysis. Similar to Elizabeth Gooding’s recent article on Debunking Definitive Crossover Claims, there are a lot of variables that go into defining sustainability and what you print on and how you print will have an impact on the calculation.

Some industries do have specific certification programs designed to reassure brands and consumers of their eco-credentials. A well-known one in the textiles area is the Oeko-Tex® Passport. Gaining specific product certification involves demonstrating the formulation meets certain user safety and environmental requirements. This can be a big help to selling into a market that is relatively open in terms of B2B sales options.

Beyond the chemistry alone, inkjet as an additive manufacturing method does certainly have some key advantages compared to analog approaches, such as only printing as much as you need and reducing wastage, etc. These often are the driver for financially-led decision-making based on total cost of print but also have a knock-on benefits for more sustainable business practices, and Pat McGrew has also done a great job of discussing this aspect of sustainability in a number of posts you can find here on Inkjet Insight.