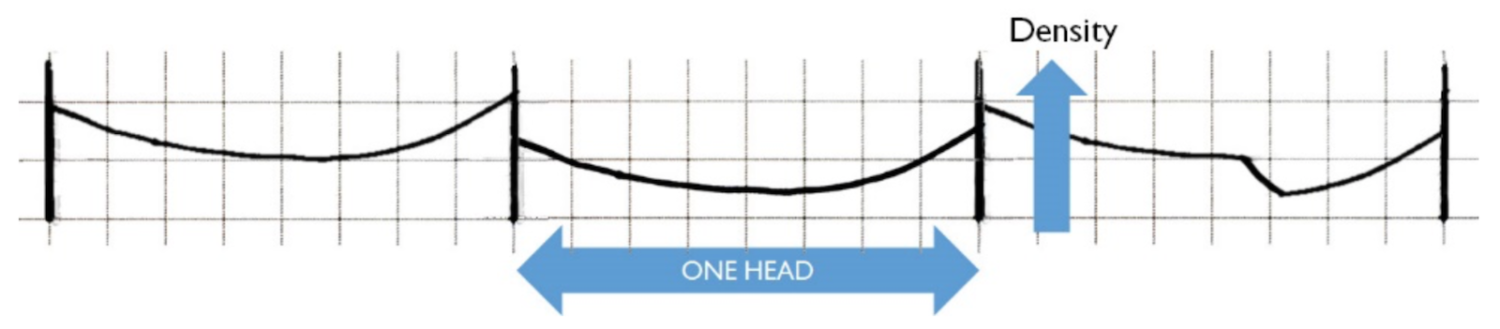

ScreenPro with PrintFlat technology reduces non-uniformity, commonly known as the inkjet smile. Source: Global Graphics

Release from Issuing Company

Cambridge UK, 10th July 2018: A new version of ScreenPro™, the ultra-high-speed screening engine tuned to smooth out imperfections in inkjet printing, is launched today by Global Graphics Software, introducing an innovative technology that reduces non-uniformity across the web, commonly known as the inkjet smile.

ScreenPro Version 2.0 introduces PrintFlat™ technology that mitigates the artifacts caused by variation within a head, between heads or wear on the head itself. It does this by being able to address every nozzle separately on any combination of head and electronics, to achieve very fine granularity.

ScreenPro will revolutionize the inkjet market by opening up opportunities for print service providers to produce higher value new products that could not be printed with previous solutions because the quality was simply not good enough.

ScreenPro can be applied to any inkjet technology and print industry workflow and can be added to presses already on the market, or incorporated into an inkjet press that’s still on the drawing board.

“Our customers wanted a technology to address the banding that inkjet print bars commonly display,” explains Tom Mooney, ScreenPro product manager. “Print heads don’t have a uniform density distribution across the head resulting in visible banding. Different print heads will have different baseline densities and while these can be corrected by “tweaking” voltages this is time consuming and can affect the life of the heads.

“PrintFlat provides a calibration that corrects for these defects providing a flat, uniform density distribution across print bars. In addition to making improvements in quality ScreenPro 2.0 provides significant performance improvements and the ability for “Real Time” screening driving data to the press at full speed.”

ScreenPro significantly improves the print quality from inkjet print heads by addressing many quality defects, as well as banding, such as chaining and mottling, that are difficult and expensive to correct mechanically.

It is supplied to press vendors either as a cross-platform development component or with a full branded user interface. As a development component ScreenPro integrates seamlessly into a workflow solution. Multiple ScreenPro engines can be run on the same server or offloaded onto separate computers. This parallel processing of screens leads to blistering speeds, especially with dedicated ScreenPro engines sending print data at press speed directly to the drive electronics driving individual print bars for each color.