This series profiles companies focussed on offering custom-developed inkjet printing solutions to their customers. Some of the basic considerations have been laid out in the introductory article here.

For consistency, we are examining the company basics and the typical types of solutions each company offers. Please keep in mind that most companies will happily evaluate solution requirements that are not covered in their core markets and that companies do evolve over time.

Industrial Inkjet, the company

Industrial Inkjet Limited, in short: IIJ, was founded in 2005 by John Corrall in the UK. The company started as an agent for inkjet heads from Konica Minolta. Still today, IIJ is the sales and technical support centre for Konica Minolta Inkjet heads and components outside of Asia. However, the company is independently owned and not part of Konica Minolta.

Besides later also reselling inkjet components for original equipment manufacturer (OEM) customers, the company progressed to develop its own value-added technology solutions with a range of monochrome and colour inkjet print modules and established an engineering team in 2007. The first print module was sold the following year. The company now offers the full gamut from inkjet heads and components to complete print modules for integration into a wide range of print lines and production equipment. IIJ designs and produces some of its own electronics and develops ink management systems and software to drive the solutions. Additionally, the company provides training on inkjet technology and components.

Today the company has about 60 employees, spread across sales and support of the Konica Minolta inkjet components and the inkjet print module business. IIJ has showrooms in the UK and the US. In July this year, it shipped its 1,000th print module.

Applications and markets served

IIJ offers print module-based custom solutions for a range of 2D-print applications. Although many applications are covered, there are three main usage areas served today:

- Security printing (ID documents, plastic cards, fiscal recovery stamps, and brand protection)

- Packaging (including blister foil, flexible packaging, labels, metal/plastic containers, carton, pulp packaging)

- Furniture (edge banding and direct print on wood surfaces)

In addition, IIJ has supported the development of wide format, sheet-fed, ceramic, and direct-to-product print systems as well as functional print solutions including optical lens and display coatings, solder mask and legend printing for electronics, solar panels, antennae, and other uses. Wallpaper printing is a new capability that was exhibited at drupa 2024.

The print modules can be for end-user retrofit, both on new and existing equipment, that can include the supply of web extensions as well additional material handling modules, but many of its systems are supplied to OEMs and integrated into larger systems, for example in passport manufacture.

The systems are often developed according to the customer requirements. After a feasibility test, samples are produced and the design of the imprint solution then developed. Prices of the systems vary significantly, with entry imprinting monochrome print modules starting at €25k and could reach the one million Euro range for high-end CMYK print requirements.

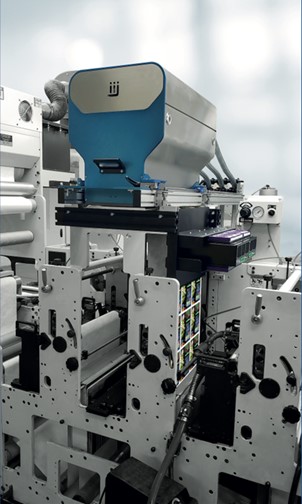

Typical CMYK Inkjet retrofit application with web extension on a Mark Andy label press

Technologies and devices

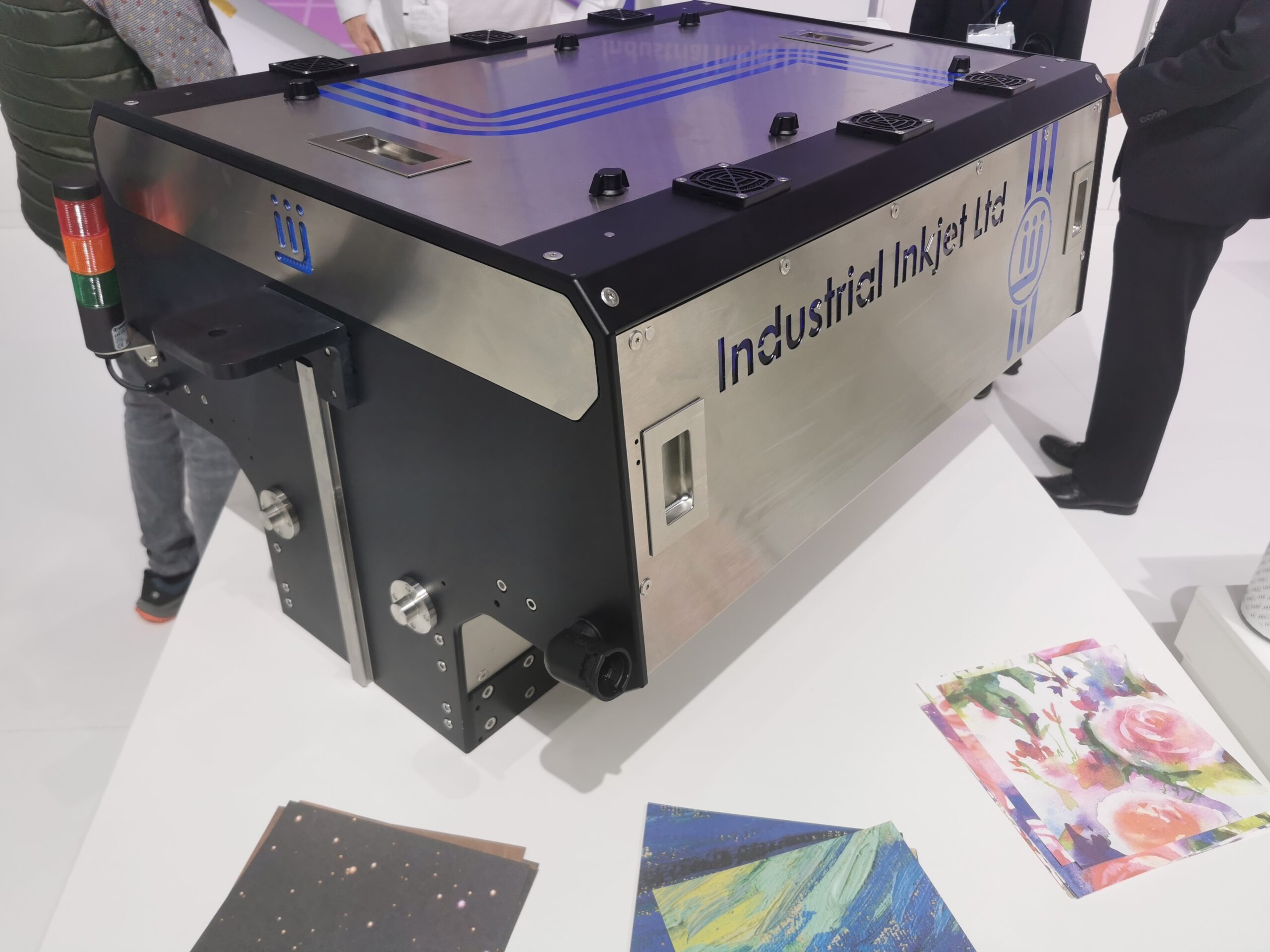

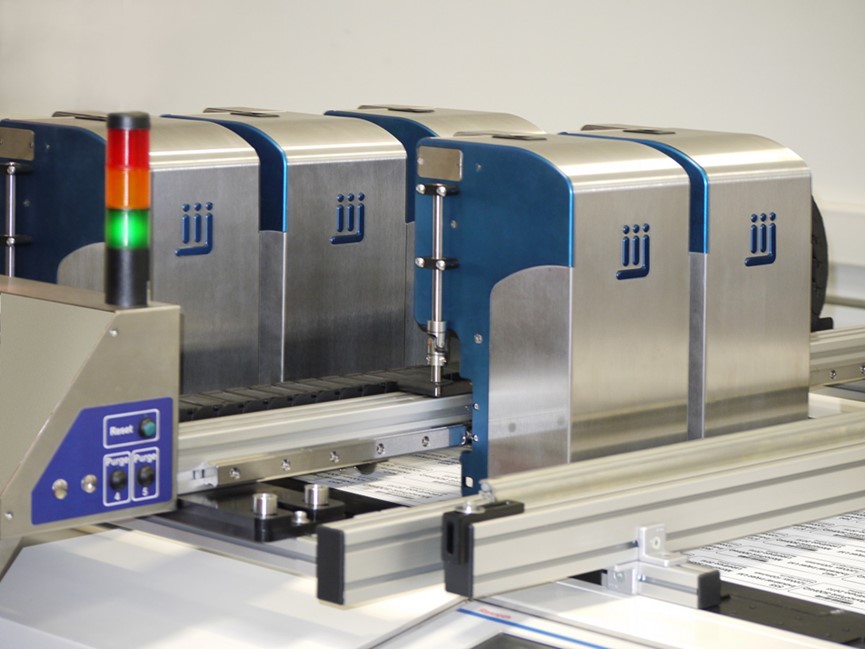

Industrial Inkjet is the sales and technical support centre for Konica Minolta Inkjet outside of the Asian region and this enables them to have in-depth expertise in these heads. Accordingly, IIJ works exclusively with Konica Minolta print heads in all its products. Solutions range from monochrome to four-colour print. Both single-pass and multi-pass printers are offered. For many years IIJ has been manufacturing print modules, that form the basis of most bespoke solutions. High print speeds up to 200 m/min from a single row of heads can be achieved. Widths up to 597 mm (23.5”) are available.

The 3rd generation IIJ CP562mm CMYK imprinting print module as shown at drupa 2024

In addition, to complete, tailored projects, IIJ markets more standardised inkjet print module products. These include their SMP (small mono print) MP (mono print) and CP (colour print) ranges. Multi-pass and single-pass solutions are available, although the multi-pass units are mainly designed for lab testing but can be used for low-volume production as well. The single-pass solutions can achieve high print speeds of up to 300 m/min. Widths up to 597 mm (23.5”) are available as standard but custom systems up to 1.5m wide have been supplied.

Multiple IIJ MP72 mono dual print head system printing QR Codes on cartons at 300m/m

Inks and substrates

The company has its own ink technology team mostly for application and fluid qualification. Besides the usual aqueous and UV inks, specialty ink types like security inks, glue, functional fluids, and furniture inks are offered as required. Different types of security ink e.g., DNA taggant based, tailored to user requirements are also available.

The printers from IIJ support a wide range of substrates, ranging from paper to different packaging types and specialty materials.

Sales, service, and geographic coverage

Although the direct sales and service coverage is in North America and Europe, where also most of the installation is, IIJ has several print module installations in Asia. Its OEM customers have multiple installations in all countries. There are two showrooms located in the US and Europe.

The systems are sold and serviced directly by IIJ as well as by its OEM partners.

What sets Industrial Inkjet apart?

Industrial Inkjet focuses on inkjet solutions that are configurable and flexible with a wide range of ink/fluid capabilities. These solutions can be tailored to what the customer needs.

They differentiate themselves due to their wide breadth of capability. The company states that “we do what others won’t do”.

Compact Konica Minolta print heads result in more compact inkjet print modules that are easy to integrate. These print heads are known for robustness as well as a wide range of fluid support. The use of digital waveforms also means OEMs and end-users can quickly adopt new fluids/inks without being dependent on the print head manufacturer to do this work.

Contact

Industrial Inkjet Limited is based at Buckingway Business Park, Swavesey, Cambridge in the UK

Website https://www.industrialij.com/

See the most recent profiles of C-marx and MCS in the Bespoke Integration department

This series on inkjet integrators will continue