In my previous post Inkjet Ink – Chemistry Matters, I provided an overview of the ink chemistry and colorant options available in the production print market. In this post, I’m going to drill down a bit on the carriers for colorant used in the major categories of inkjet ink and why these differences matter when selecting inkjet for a particular purpose.

Aqueous

The ink choice that is the most common and familiar to most of us is aqueous. Water-based inkjet fluids are equally applicable to thermal printheads, their piezoelectric drop-on-demand counterparts and continuous inkjet (CIJ) printheads. The biggest attraction is in the relatively low cost of the materials, thus increasing the competitiveness to other print methods. In recent years, the ecological sustainability of a product is considered of increasing importance and water that is evaporated from an ink offers no specific hazard to the environment.

Optimizing pigment dispersion is the key to maximizing the color gamut for aqueous inks. If the pigment is dragged into the paper by the absorption of the water, the chroma of the pigment will be reduced. A lot of pigment dispersion for water-based inks are stabilized by charge around the pigment, thus keeping the particles separate in the highly polar water base. When the ink is printed, the pigment is separated from its solution by fluids applied to the paper at the inkjet device or at the mill itself. The separation of the colorant, in essence, becomes paper specific. For uncoated paper applications the industry has incorporated methods using a pre-treating that is designed to work specifically with the ink to separate out the pigment. This pre-treatment can also be jetted (like in HP machines) or applied by rollers (as it is for the Ricoh VC60000).

Another way to control the pigment is the use of polymers. Polymers are being used as a dispersing resin which surrounds the pigment particles assisting the pigment colorant to stay on the surface. When extra polymer resin is added to the ink chemistry, but does not specifically attach to the pigment, it is called a binder. Although not directly attached to the pigment, its role is to stick the particles to the paper fibers and it is central to giving the ink some resistance property.

Co-solvents, like glycerol, and surfactants are used to control the penetration of colorant into the paper. This is closely linked to the sideways interaction between color, known as ink bleed. The amount of these materials in the ink also determines how easy or hard to dry the ink will be. Quick drying is a good thing for fast printing but it has to be offset against the ability to maintain the nozzles in a good condition. This is a careful balancing act that is optimized alongside the printer design, both in terms of the drying mechanisms themselves, as well as any automated head maintenance function.

Oil

Much of the discussion for water-based inks also applies to oil. Pigment needs to be dispersed carefully in the vehicle to create stable inks and the blend of oils chosen to control the absorption plays an important role. Similar to water-based inks, some higher fraction oils will be retained into the substrate even once dried. According to a leading manufacturer, one of the main advantages over water-based inks is the reduced paper distortion during printing. Unlike water based scenarios in which the carrier is pulled quickly from the saturated paper fibers causing curl and cockle, oils drying involves a slower controlled drying which greatly reduces this cross-fiber pull within the printed media.

Hot-melt

Xerox and Océ have long been associated with this type of ink, which has a strong pedigree of different uses across the industrial inkjet sector and whose roots can be dated back to the early teletype printers of the 1970’s. It can only be used in certain print heads that can withstand the heating required to get the solid ink to turn to a liquid with the right viscosity to jet. Often exceeding 175°F (80°C). As a result, its use is limited to piezoelectric print heads, which use a squeezing action to form the drop.

The ink is usually formulated from wax materials, the behavior of which is largely defined by its melting points. Since the film can be quite brittle, plasticizers can be added for flexibility. These may be oils or surfactants although the latter won’t contribute quite as much to the wetting as they do for liquid inks. The color can be dye, if it is soluble in the wax, or pigment that is dispersed. Incorporating pigment can be more complicated than other ink types.

When printed, the ink ‘freezes’ upon impact with the substrate. When depositing on paper, one of the main advantages is the much-reduced drying requirement and the ability to control the low-viscosity droplet interactions that cause ink bleed. As a rule, penetration is much-reduced and thus the color is held right at the surface. A controlled amount of penetration can help with gaining a physical bond between the paper and ink, which can also be enhanced by choosing polar or acidic waxes, for example.

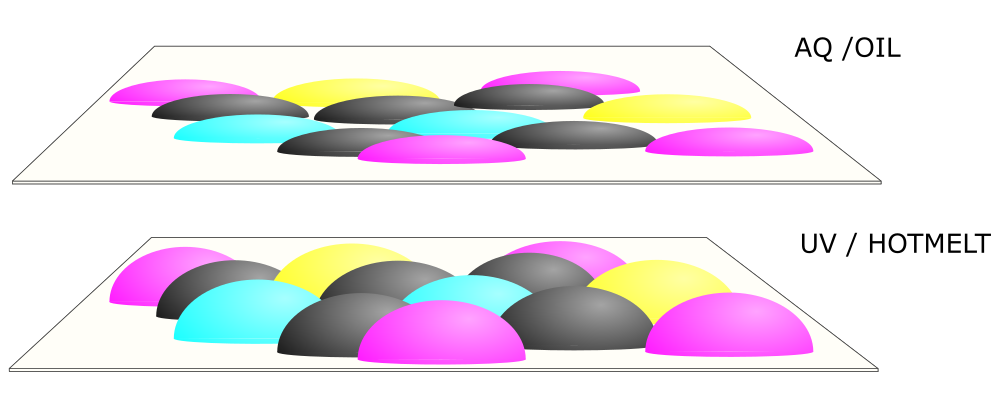

Controlling gloss and color is one area of practical importance for competing with other ink technologies. Naturally the piles of frozen drops of different colors (shown below) would form a relatively matte appearance that would also limit the punch of the color due to reduced light transmission.

By controlling the rate of re-crystallization through reheating, the film property can be adjusted. It is also possible to flatten the drops by ‘fusing’ them, like in toner printers. This is the approach used in certain Xerox printers, where the ink is initially applied to a drum. Hot-melt inks can also be made more resistant by adding UV curing.

UV-Curable

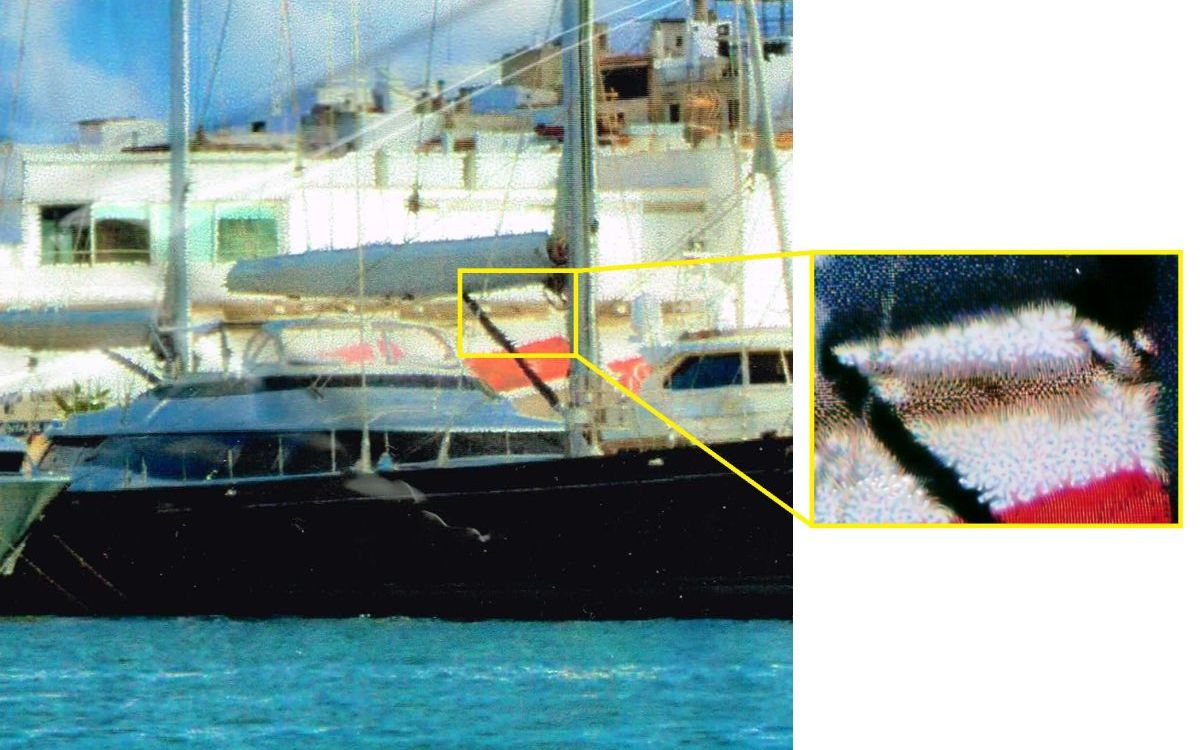

This ink type is the basis for the explosion of inkjet in the wider industrial sector due to its relatively ‘easy’ handling and wide gamut of available materials already used in traditional printing, such as flexo and screen. In the main type being used in inkjet, known as free radical curing, the building blocks are acrylate ‘monomers’. Monomers are quite small molecules with one or more reactive groups that tend to be liquids at room temperature. By including a suitable ‘photointiator’ in the mix, and setting off the reaction with UV light, the ink turns solid instantaneously. Applying UV ink successfully to paper has always been the difficulty. However, since the absorption of un-cured ink into uncoated paper prevents the subsequent cure, leaving unsafe levels of un-cured monomers hanging around can allow drops to dive too quickly in the Z direction with the paper fiber. Since the color is dispersed into the ink’s monomeric base, the color tends to be lost too. In contrast, on higher hold out -coated papers the ink wetting can be challenging and without proper curing, such as UV-LED pinning, the ink bleed and coalescence which happens in the X and Y direction of the coated paper surface can be severe, as in the example below:

UV ink is more commonly used in industrial inkjet printing than high speed inkjet as it requires slower production speeds to allow proper curing and jetting. UV chemistry can be customized or tuned for adhesion and wetting onto a range of different materials by tweaking the chemistry. Like hot-melt above, by sitting right at the surface with a controlled amount of drop spread, controlled by the paper temperature, then gives it a beautifully controlled resolution, gloss and color.

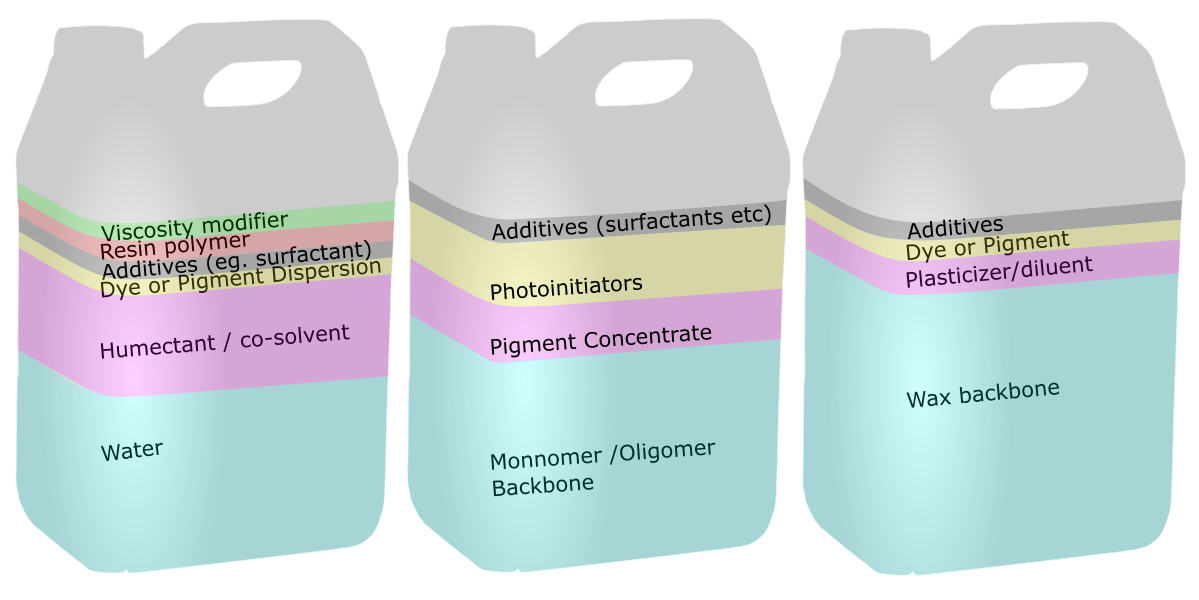

We can most easily summarize the different components discussed that go into our different ink types in the image below:

An ink’s carrier is an important piece of the compatibility to the print process. In our next article, we will dive deeper into the most commonly used ink, Aqueous.