Many online printers run a mix of offset and digital printers today, the latter is usually electrophotographic (EP). Ideally, inkjet should enlarge the market for any company using it, but in reality, it is also competing against existing technology as well. There are some considerations on making the best use of inkjet.

Quality

15 years ago high-speed colour inkjet started out with a quite basic quality level – often termed business quality, as it was suitable for the business of transaction print. Inkjet technology came a long way since. The latest devices pushed imaging resolution to 1,200 x 1,200 dpi, feature new inks, better drying and improved drop management, that give inkjet (CF and cut sheet) a quality closing in on offset, sometimes even surpassing it.

This view is shared by all players in online print. If no special colours or varnishes are required, inkjet can reproduce standard jobs and customers accept the quality. Helpful is the higher gamut that most inkjet inks offer in process colours compared to standard offset. The Landa press is an exception in offering 7 colours for an extended gamut as an option – allowing in this case even for premium products with a very high gamut.

Print quality is very much press dependent and while the top-of-the-line presses have great quality, inkjet presses with a lower quality level can be more economical and still be fit for the purpose.

Paper

Paper is still an important variable in inkjet print. Print quality in inkjet is very paper dependent. With improving technology the market relies less on inkjet optimised papers, still coated papers can be challenging and can require a precoat. Using primer does increase the print cost slightly however, it helps to extend the paper range and makes the paper supply more flexible. To an even larger extent than in print quality, the range of usable papers is inkjet press dependent. A special case is the Landa presses, as the nanographic process makes them quite flexible in terms of substrates.

Online printers typically have limited paper choices and provide customers with paper options – instead of having customers demand certain papers. This benefits inkjet, although it requires some research and testing.

The current paper shortages have an influence as well. A boon for inkjet is, that inkjet can save paper (e.g. in makeready) compared to offset. It also helps to offer shorter runs efficiently when paper is scarce. A factor for insecurity is that the tried & tested paper might not be available right now.

Cost of Print

Inkjet ink costs tend to be lower than EP click charges. This is especially true for CF inkjet. A user switching from toner to CF inkjet reported a cost saving of 50% on the click paid before. Obviously, ink pricing will differ a lot among systems and high-quality systems tend to have higher ink prices. The price per litre is not a good indicator however as the yield figures in as well.

Important to note is that ink pricing is coverage dependent and the higher the coverage, the higher the cost per print – while click charges stay constant regardless coverage. There is an opportunity to route high coverage jobs to click-based printers if the workflow software allows for that kind of routing. However, it pays to look at the contract

Another cost factor to keep in mind is paper. Roll paper tends to be cheaper than sheeted paper and savings in the range of 10% are possible. When compared to SRA3 paper the savings can be even bigger. A bit of research pays off here as well, as local prices can differ, and some formats might be more expensive than others.

Productivity

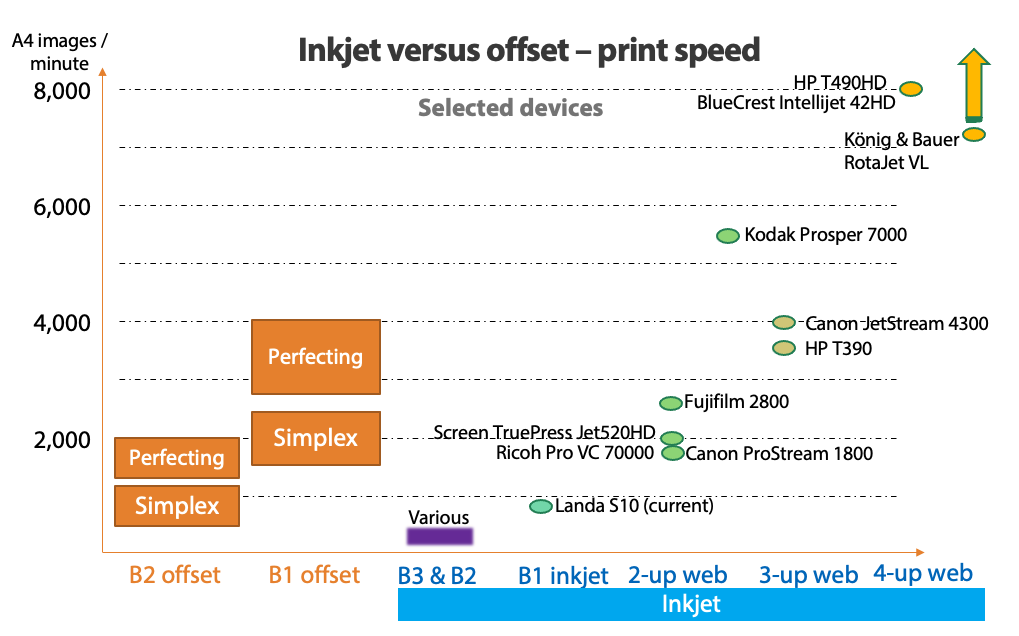

Inkjet presses tend to have a much higher productivity than EP presses. B3-based inkjet printers have approximately the double speed of a similar sized EP printer. The bulk of 2-up CF inkjet presses typically have a 10 times higher output. Wider CF presses would be even a lot more productive, however, they are not used in online print yet. Filling this capacity right away would be a challenge and multiple 2-up presses allow for redundancy and running different substrates concurrently. Also, the uptime of inkjet presses is higher than for EP, which adds to the higher speed. Accordingly, a CF inkjet printer can replace several EP presses.

A 2-up inkjet press is already surpassing the speed of a B2 offset press, hence closing the productivity gap between digital and offset.

Overview speed of selected inkjet and offset presses

Finishing

The importance of finishing is often underestimated. A print product is not ready to ship until it is finished. Furthermore, finishing does not only add value, it can influence the overall cost and quality of preceding process steps as well. An advantage of digital print is, that prints are dry and ready to process right out of the press.

More important is that digital presses can print images in sequence, for example producing a collated book. This does not only make collating devices obsolete, it allows for inline finishing as well. Adding in all that can go wrong when printing signatures, handling, and collating them, this typically drives up the breakeven against offset to 2,000 to 3,000 copies – sometimes even higher.

If tuned to the right application mix inline finishing can be a powerful efficiency driver, by saving time, labour and process steps. However, deciding for an in-line or nearline solutions needs a careful evaluation. Being too limited in the application range, too much downtime of components or long set-up times can render in-line finishing practically useless.

Ganging or not?

Online printers became very efficient in using offset presses for short runs by ganging multiple jobs on a plate. How to gang orders and how to separate them again in finishing is often a core competency of online printers.

An advantage of digital print is that all kinds of small runs can be produced efficiently, and orders would not need to be ganged anymore – or to a much smaller extent. Once an order is in, it can be printed multiple-up as a single short run. This does simplify finishing, reduces possible mistakes and the amount of reprints if something went wrong. It also allows printing changing numbers of copies without extra costs (while on a ganged sheet all jobs have to have the same run length).

Logistics

Most online printers are pure sheet-fed shops. Adding a roll-fed device can feel as it would complicate processes. Adding a CF inkjet press will require roll paper handling equipment, such as forklifts and logistics for storing roll paper. Feedback from CF users indicates that this is less complicated than expected.

The logistics requirements stretch into the press. Roll paper is much more difficult to change than sheet paper. It will require pre-planning and batching to keep the changes at a minimum. Automated web change equipment can lessen the burden, but it requires an additional investment and still, change-over time and waste paper are created.

Getting inkjet moving

So far inkjet had more impact on EP installations than on offset volumes. With improving productivity and lower costs inkjet will eat more into offset volumes as well. Additionally, run lengths ordered are decreasing which will drive more inkjet volumes in any case. Environmental considerations will drive inkjet as well.

Online printers might be set in the ways they work and spent a lot of effort in optimising their processes. Inkjet is putting some of these ways into question. For example, a fast and reliable MIS/workflow for routing jobs will be necessary that automatically sends jobs to the most efficient printer – keeping in mind other aspects such as maintenance, load-balancing or papers. An inkjet user stated that he even would route jobs slightly beyond the break-even against offset to the inkjet press, as the inkjet production flow is simpler.

Inkjet technology has been continuously improving and online printers are taking note. They do expect to see further improvements, which might hold back some decisions today. A jump in inkjet uptake might come sooner than we think, however.