If you are developing an inkjet system, you’d better like to move it like King Julien in Madagascar. In previous articles I have covered inks, heads and a little about substrates, but when it comes to integrating inkjet systems there is one important factor that links those three tenets together, and that is the engineering of the printing system themselves, including our focus for this article – motion systems.

Why is accurate motion so important?

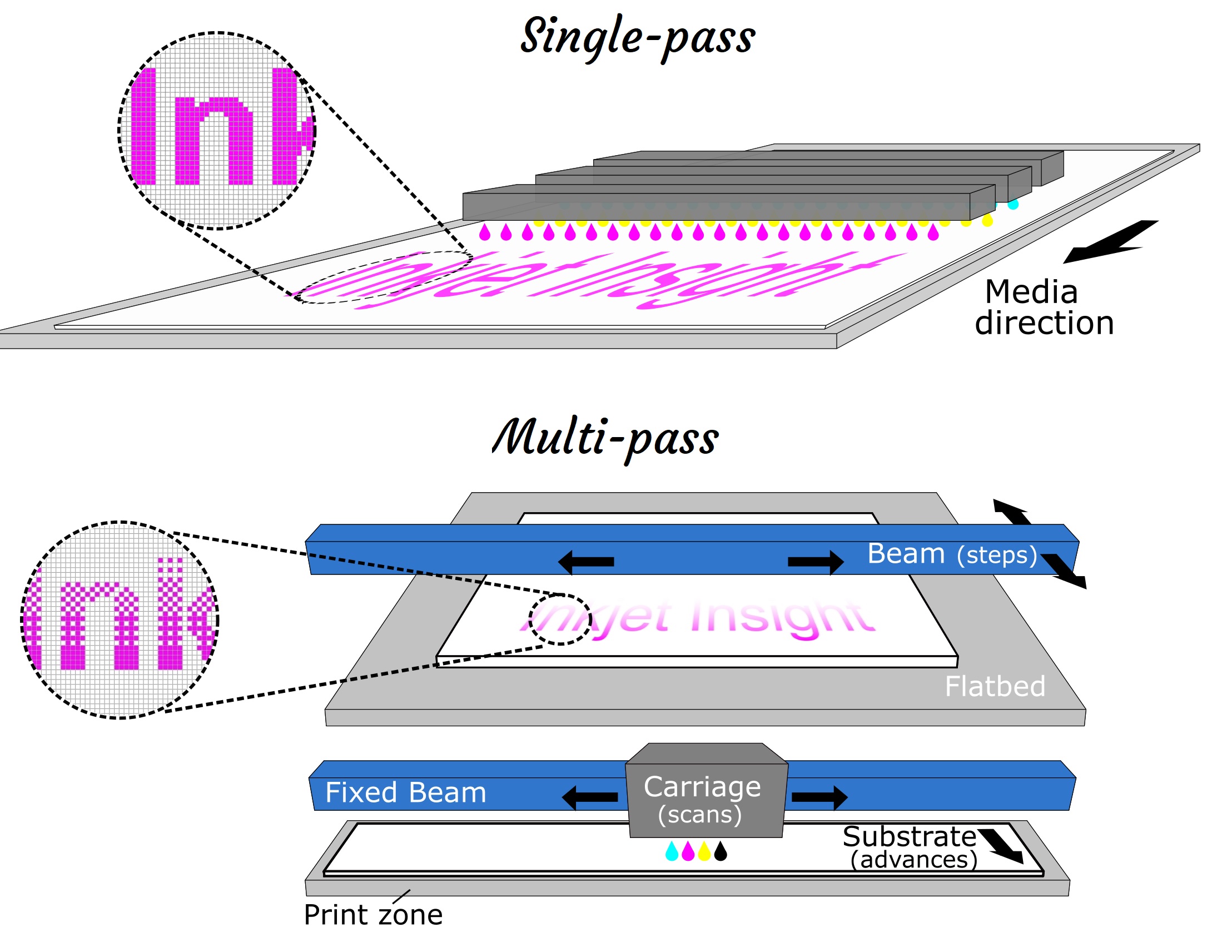

Stop and think for a moment about what we generally mean by “offset quality”. Often that target in inkjet terms has been taken as synonymous with 1200dpi or higher resolution processes. With modern high-speed printers, that means moving webs at 1000ft/min while delivering throw accuracy of better than 1/1000th of an inch under an array of heads. Motion is necessary for speed and consistent, predictable motion is necessary for accuracy. There are two main ways that motion happens in inkjet systems in terms of positioning printheads relative to the substrate, single-pass and multi-pass.

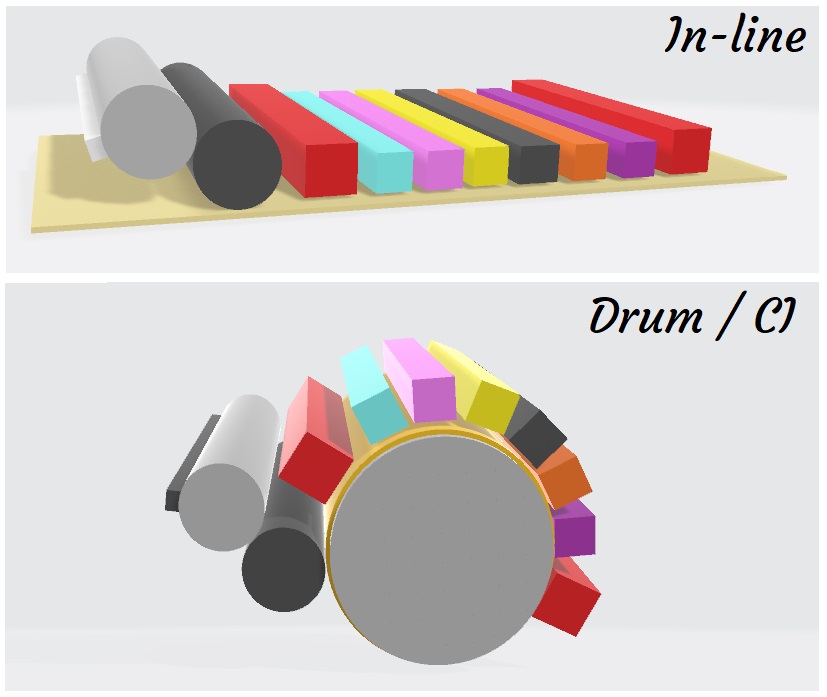

Most production inkjet technology used for printing on paper is single-pass in order to get the higher productivity enabled by addressing all the dots in the raster in single trip under the static printheads. Well, I sat say static but there are some systems where those heads have some intentional movement, we’ll come back to that soon.

Figure 1 The different mainstream printer architectures which we will consider.

Most people are familiar with multi-pass because of the inkjet printers we have at home. The design of most large format printers evolved from home-office systems by mounting heads on ever longer rails over an incrementally stepping substrate range. The main advancement through the last 20 years has been the increasing scale of the fastest moving part – the carriage. You can still find five meter rails running carriages with a single 1” wide head per color, but they run at snail’s pace compared to the huge Durst, EFI and other machines built around 20-60 DoD heads, each with 1000+ nozzles.

Such a large carriage means you are moving bigger mass faster which, thanks to Sir Isaac Newton means bigger, meatier motors to get the acceleration and stronger more rigid rails to avoid deformation. The ability to adjust all the movement axes for best performance upon site install is just as important to today’s high-resolution high-speed graphics printer as it was for the $1m single-print-head OLED printers which I started my inkjet career by optimising the printing quality for.

Single-Pass Challenges

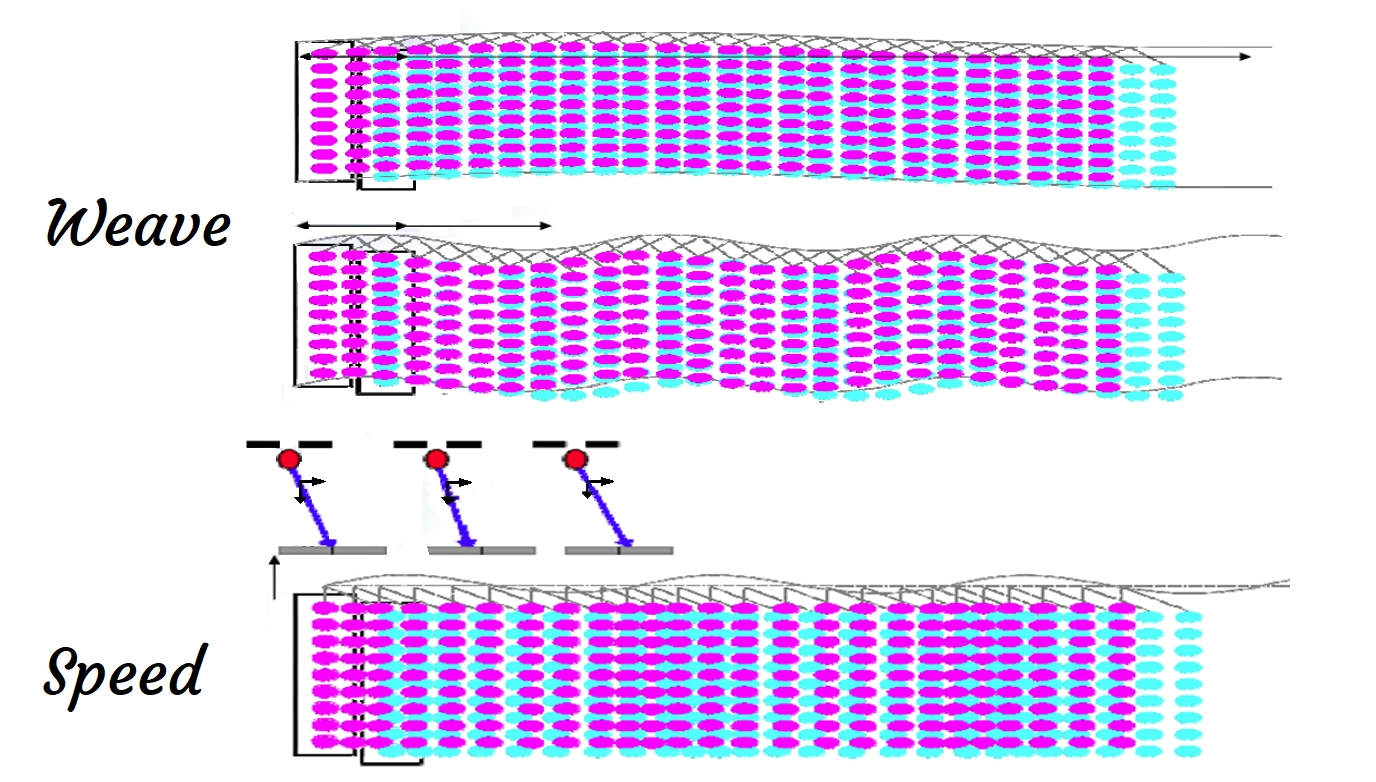

Most issues relating to single-pass precision arrive from two things, speed control and substrate movement consistency. In roll-to-roll production inkjet machines (and their bigger brethren used for other applications like corrugated, folding carton and décor) speed control is a little easier, but closely related to tension control, which can influence web weave when running over rollers. The side-effects of weaving tends to be more noticeable as the print zone becomes longer, since even tiny angular changes in substrate feeding can result in dot placement errors bigger than a pixel due to the distance between successive colors.

Figure 2 The drop registration issues with different substrate movement errors. ©InkJet Academy.

An advantage offered by heads, like Memjet, especially when using a single module is that all colors are printed within very close proximity. Although the head needs to be aligned reasonably well, the substrate handling can be less sophisticated enabling the use of lower cost systems with quite good print quality.

At the other end of the spectrum are the highest speed printers that are using multiple print bars per color to share the dpi in the print direction thus increasing the print zone length even further. The trend in these systems is to utilise cylindrical print zones known as continuous impression (CI) drums since the individual impression rollers of a serial architecture are replaced by a single large roller. Some well-known production printers do this too.

That does not work for rigid sheets though. In cases like ceramic tiles, wood printing and glass printing the handling system has to be able to cope with these challenges while keeping everything flat and precisely registered across the print zone, whilst also having the flexibility to cope with different thicknesses of sheets.

Figure 3. Different types of single pass printer designs

Multi-Pass Issues

The challenge of multiple passes for inkjet goes beyond just accuracy and introduces repeatability as a variable. It is necessary to deposit the rasterized image in several steps, all off which need to be well aligned in order to reproduce the carefully developed dot screening patterns. The smallest printers usually work by taking enough passes to randomise out the variations, but larger graphics and textile printers which print with 4 passes or fewer must be engineered so that the step size matches the raster pitch. In many textile devices the printers take steps that are full print-carriage width, often mistakenly called “single-pass” but more appropriately called non-interlaced multi-pass.

In small, wide-format graphics machines the advancing rollers are usually calibrated to different media, based on the friction achieved. In larger textile systems there is more likely to be a precision belt made out of metal with a strong vacuum used to hold the substrate as it advances under the head array.

Avoiding Crashes

The target material for printing is central to defining challenges and the design features to overcome them. You should be familiar with the way paper can change under different humidity conditions. For packaging the temperature of drying can have a very similar effect on polymer films. As a result, we don’t only have to worry about placing substrates accurately, we also have to be concerned with doing it over varying conditions and substrate quality and the knock-on effects that has on handling. In the most sophisticated production machines this usually involves some kind of monitoring and feedback, for example servo motors that move the heads themselves so that they track substrate movements in real time.

In textile printing, crashes between poorly controlled substrate and printheads can have dramatic effects. This is why Kyocera reinforced the side of their heads when they started selling into this market. The use of sticky belts improves the precision of handling textile materials but when engineering print bars for single-pass systems it is often good practice to add a physical barrier as protection for the heads, especially if they are sensitive to contact due to their construction (e.g. silicon).

Corrugated board printing is another application segment where crashes can be severe. The substrate quality, especially sheet flatness, can vary depending on both humidity and the packaging of the pallets. The conveyor or belt is often provided with a significant vacuum in order to suck down warped sheets. Usually, some zoning is used to allow for different boards sizes to be printer without compromising the suction.

Minding the gap

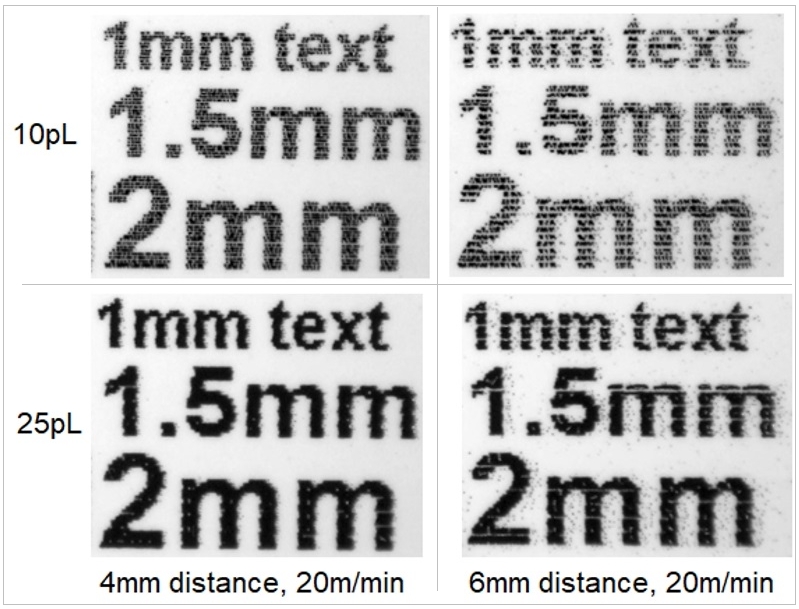

In addition to the substrate handling itself, some heads, like Seiko’s RC15636 as used in the EFI Nozomi have thicker nozzle guards which can help reduce the impact of accidental strikes but more often the mitigation is a larger print gap, which can lead to other consequences such on print quality. Larger drops can be much better at printing accurately with across larger print gaps, especially in the presence of entrained airflows introduced at higher speeds, so correct printhead selection is also important.

Figure 4. Examples of reduce accuracy and increases satellites at high distance. ©InkJet Academy.

So why bother explaining all this? If you are considering investing in an inkjet printer it is important to know how positioning and substrate handing design features have been used to ensure that print quality will be consistent. If you are building a printer, then there are some hard lessons that folks have already learned that you can benefit from. That is why your humble author presents the Inkjet Academy on regularly in both US and Europe, with the next instalment coming to Cambridge UK on 3rd/4th July. If in the meanwhile you have any questions, suggestions or correction then please get in touch.