Andy Gordon

Partner, Inkjet Insight

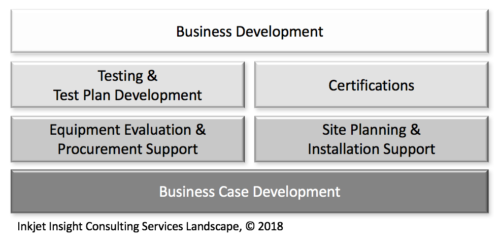

There are a lot of services that go into getting an inkjet implementation up and running smoothly. So many that I couldn’t cover all of them in a single post. Part 1 of this series discussed the landscape of consulting service options needed to maximize your investment and described services associated with building the case to acquire a press up to and including the installation process. Part 2 of this series discusses activities to drive customer acceptance and revenue including testing, certifications, and business development.

Testing and Test Plan Development

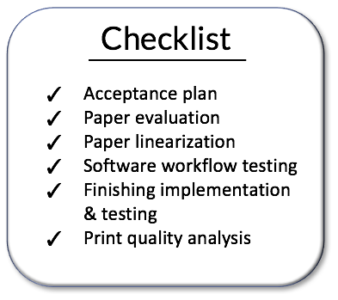

Testing occurs at all steps of your buying journey and will continue through the life of the device. It’s critical to ensure that the workflow tools you have selected work with your customer applications and that you achieve the highest possible efficiency while maintaining the quality levels required. The same holds true for finishing workflow where details make the difference between profitable jobs and painful reprints. If you are implementing solutions that involve personal data, data security protocols much be built into test processes as well as production.

Often discussed, but not always understood, is the relationship between paper, print quality and equipment settings. Testing papers, linearizing equipment, characterizing and profiling equipment are all critical to ensuring the highest possible customer satisfaction. It’s the kiss of death if you sell a job based on a test run and can’t deliver the same result consistently. Inkjet Insight provides many print quality related tools on the site, as well as guidance on best practices (some of our most popular posts if the web metrics can be believed). But, that is not a substitute for having an inkjet print quality specialists on site when you need to profile a bunch of new papers with the least down-time to your press.

Certifications

Many printers see the value in securing certifications, but too often they are viewed as a marketing cost that has no value other than creating a check next to some text on a brochure – “we have it – yay us!” We already know that printers under-spend when it comes to marketing and business development and the same holds true for certifications. They are often viewed as nice to have rather than need to have. The Inkjet Insight team advocates for embracing certifications to help ensure that your inkjet printing operation runs to its highest potential delivering high quality and consistent results aligned with customer requirements. Three key areas of certifications may be applicable to inkjet printing operations G7 (color management), FSC and SFI (paper stewardship), and a host of security certifications for secured print environments.

Business Development

In the movie “Field of Dreams”, Shoeless Joe told Ray Kinsella, “If you build it, he will come.” It’s a heartwarming story that doesn’t translate well to the printing industry. Too often printers acquire technology and hope the print volumes will materialize without doing the hard work of business development. We recommend that you begin building a comprehensive business development plan well in advance of acquiring inkjet, and then tailor it based on the capabilities of the selected solution AND your overall production portfolio. The plan should include evaluating your brand messaging to ensure alignment with your purchase, updating your web and social presence, developing marketing collateral and direct marketing campaigns that are unique and tailored to your client base, training your sales staff to sell solutions and the value proposition of inkjet printing, and hosting events to show off your operation and teach your customers how to get the most out of your investment. Look for a consultant that has experience with inkjet printing operations, your target application types and knows how best to position your company to maximize your inkjet printing opportunity. If you don’t have a dedicated marketing staff, there are companies that can help you manage your social media presence and keep marketing content fresh. OEMs can be very helpful with developing customer events and case studies that will help build your brand, but rarely have the band-width or expertise to help you evaluate your market positioning and strategy or support on-going content development.

Many Hands Make the Work Go Faster

In addition to the range of services mentioned throughout this post, you may want to consider services to help redesign or reengineer your customer’s documents and applications to take advantage of inkjet and enable “value pricing.” You may need training to build your inkjet knowledge or learn to use tools for estimating ink coverage and job costs. Maybe you are only buying a single device and need support to develop a disaster recovery and business continuity strategy. For any of the services we’ve discussed, there are a variety of options for getting help. My point is, plan ahead for the help you are going to need and factor it into your buying decision.

There is no better time to negotiate for services with your OEM than when buying a new press, and understanding the services that the OEM can deliver (directly or through a partner) should be part of your competitive analysis.

Editor’s note:

The Inkjet Insight team has extensive experience helping clients successfully navigate the inkjet equipment buying journey and is positioned to be your partner to ensure long term success. We deliver on this value proposition with our content and resources throughout our website and can custom tailor consulting services to meet your unique requirements. Please reach out to our team if you have any questions regarding your buying journey and consulting services that you may need to address specific requirements. If you need services that we don’t offer, we would be happy to try to introduce you to someone who can.