Surprising Level of Manufacturer Interest in Single-Pass Inkjet for Corrugated

It’s July and drupa 2020 should have just finished. Although drupa is geared towards commercial print a lot of the product news timed for drupa centered on packaging print. Here is one more. In June, Domino introduced the X630i, its first digital inkjet product offering for corrugated.

Founded in June 1978, with its global headquarters in Cambridge UK, Domino Printing Sciences has been in inkjet printing technologies from the start. Domino was acquired by Brother in 2015, but enjoys a great degree of independence. Domino has been very active in label print in recent years and made a foray into document printing as well. The company has over 2,800 employees including 600 service technicians.

The launch event was opened by Dr Sean Smyth giving an overview on the global corrugated market. According to his data inkjet already accounts for about 7.9% of the printed value in corrugated, but only 0.7% to 0.8% of the global printed surface area and tonnage. This is set to grow rapidly. The arguments for digitally printed corrugated are compelling: test marketing, shorter runs, faster response, more SKUs, more high-quality graphics and versioning – finally it can free the existing flexo presses from the burden of short runs to focus on profitable longer runs.

Enter the X630i

The X630i supports sheets up to 1,6 x 3m (63” x 118”) and has a print width of 1346 mm (53”). Kyocera heads with 600dpi resolution are used within Domino’s iTech inkjet platform. iTech refers to modules for ink optimization and conditioning, an automated stitching of printheads and automated cleaning and capping of printheads.

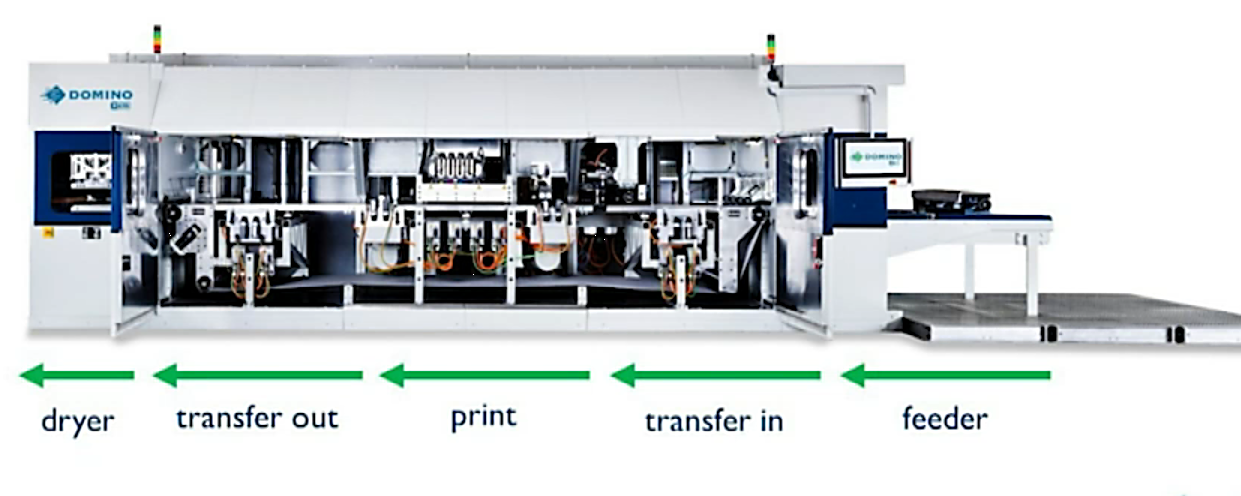

The press has been designed to be relatively compact. After a servo-controlled feeder the sheets are checked and cleaned in the “transfer in” module. During all processes the sheets are held by a vacuum belt. In the “transfer out” module the sheets are “checked if the print is steady” according to Domino. This is followed by a compact near-IR dryer. Domino also stressed that the press is highly automated

Domino X630i postprint corrugated press components

Domino inks are based on novel, water-based ink technology labelled AQ95 i-Tech PolyM. The inks are pigmented and contain a polymer component to allow printing on a wide range of substrates. They are stated to be compliant to various food safety standards, like Nestle, Swiss Ordinance, EuPIA etc. Coated and uncoated stock is supported and no primer and precoat is necessary. There is no option for white so far.

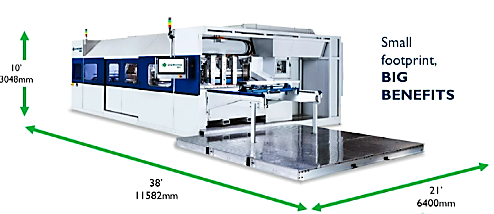

Domino joins an increasingly crowded field of post-print cut-sheet inkjet presses for corrugated. The company sees its advantages in the small footprint of the printer and the printer being fully enclosed, so it can be operated in common production floor environments. With a length of 11.5 meters (38 feet) and a weight of 26 tons it is still hardly a small device.

Domino X630i Footprint

Finn MacDonald, president of Kentucky-based Independent II, is set to become the first customer. The traditional full-service sheet plant banked on flexo so far and the X630i will be the first step into digital. The printer was supposed to be on the way to Kentucky, but COVID put a delay on the installation. Independent II choose to go with Domino on the experience the company has in digital label print its sheetfed heritage. Independent II plans to bring higher quality graphics to its customers – compared to what is possible with their flexo equipment – and to streamline their internal workflow and better manage inventory.

Post-print Corrugated Single Pass Inkjet

|

Vendor |

Barberan |

Domino |

Durst |

EFI |

HP |

König & Bauer |

Xeikon |

|

Model |

Jetmaster |

X630i |

Delta SPC130 |

Nozomi C18000 |

C500 |

CorruJET |

Idera |

|

Max sheet size |

1,89 m width 74.5“ width |

1,6 x 3,0 m |

1,3 x 2,8 m 51“ x 110“ |

1,8 x 3,0 m 71“ x 118“ |

1.3 x 2.5 m 52“ x 98“ |

1,3 x 1,7 (2,1)m 51“ x 67“ |

1.6 x 2.8 m 5‘3“ x 9‘2“ |

|

Linear speed |

Up to 80 m/min 262 fpm |

75 m/min 246 fpm |

Up to 120 m/min 394 fpm |

Up to 75 m/min 246 fpm |

75 m/min 246 fpm |

Up to 120 m/min 394 fpm |

Up to 150 m/min 492 fpm |

|

Ink system |

UV |

Acqueous |

Acqueous |

UV |

Acqueous |

Acqueous |

Acqueous |

|

Resolution (dpi) |

360 |

600 |

Up to 800 |

Up to 360 x 720 |

1,200 |

Up to 1,200 x 600 |

600×400 at full speed Up to 600×1,200 |

|

White ink |

no |

no |

no |

yes |

no |

No |

no |

|

Availability |

Available |

Announced, in beta soon |

Available |

Available |

Available |

Beta test |

announced |

* Based on Shenzhen Hanway Glory1604

The increase in inkjet solutions for corrugated in recent years has been quite remarkable. Most focus is on postprint cut-sheet printers, but preprint roll-fed solutions exist as well. Note also the concept by Inca to add inkjet printing into the corrugator itself. Additionally, scanning-head large format printers are used in corrugated. More single pass corrugated inkjet printers have been hinted at from companies such as Inca (owned by Screen) and Mouvent (owned by Bobst). There could be more to come this year, certainly from China, the biggest packaging market in the world.

It still feels a bit surprising that single-pass inkjet for corrugated spawned such a high interest from manufacturers as it requires print widths much wider than in all other page-wide inkjet applications – on a substrate that is quite challenging – in a market with high volumes but low margins usually. Still adoption has been rising rapidly despite the high price of each of these presses. The outlook remains bright with double digital growth rates forecasted, possibly even helped by more online ordering during COVID times. Despite the high growth rate, the competition among press vendors will be stiff in digital corrugated print. Stay tuned.