There is still a considerable opportunity for digital production print in the B2 format, by moving short runs from offset to digital, by consolidating EP volumes, or by opening new opportunities in on-demand print. At drupa 2016, Canon showed the Voyager, a prototype B2 inkjet press. Since then Canon collected customer feedback on a B2 inkjet press and it seems that the efforts paid off and culminated in the launch of the varioPRESS iV7.

A key for a competitive inkjet press is productivity. For one, the varioPRESS iV7 has a speed of 8,700 impressions on a B2 sheet per hour or 4,350 sheets in duplex print. With a larger sheet that supports 6-up impositioning (614 x 675 mm / 24” x 26.6”), the speed drops to 7,200 impressions/hour, equating to 720 A4 ipm (in six-up). Additionally, the iV7 has been designed for high availability and includes productivity-enhancing features like multiple paper trays and automated quality control.

Other features position the iV7 equally well for the commercial market. Uncoated paper from 60 to 450 gsm and (standard) coated papers from 75 to 450 gsm are supported, which includes light board. With a 1,200 dpi printing resolution and multi-level drop sizes, the press aims for a high print quality.

By naming the new product varioPRESS, instead of varioPRINT, Canon makes it clear that the varioPRESS iV7 is targeted at high-volume environments. Unfortunately, the press will not be exhibited directly at drupa, instead, visitors can watch a virtual presentation, including print samples and a video of the press operating at the Canon R&D facility in the Netherlands. Availability is planned for the second half of 2025.

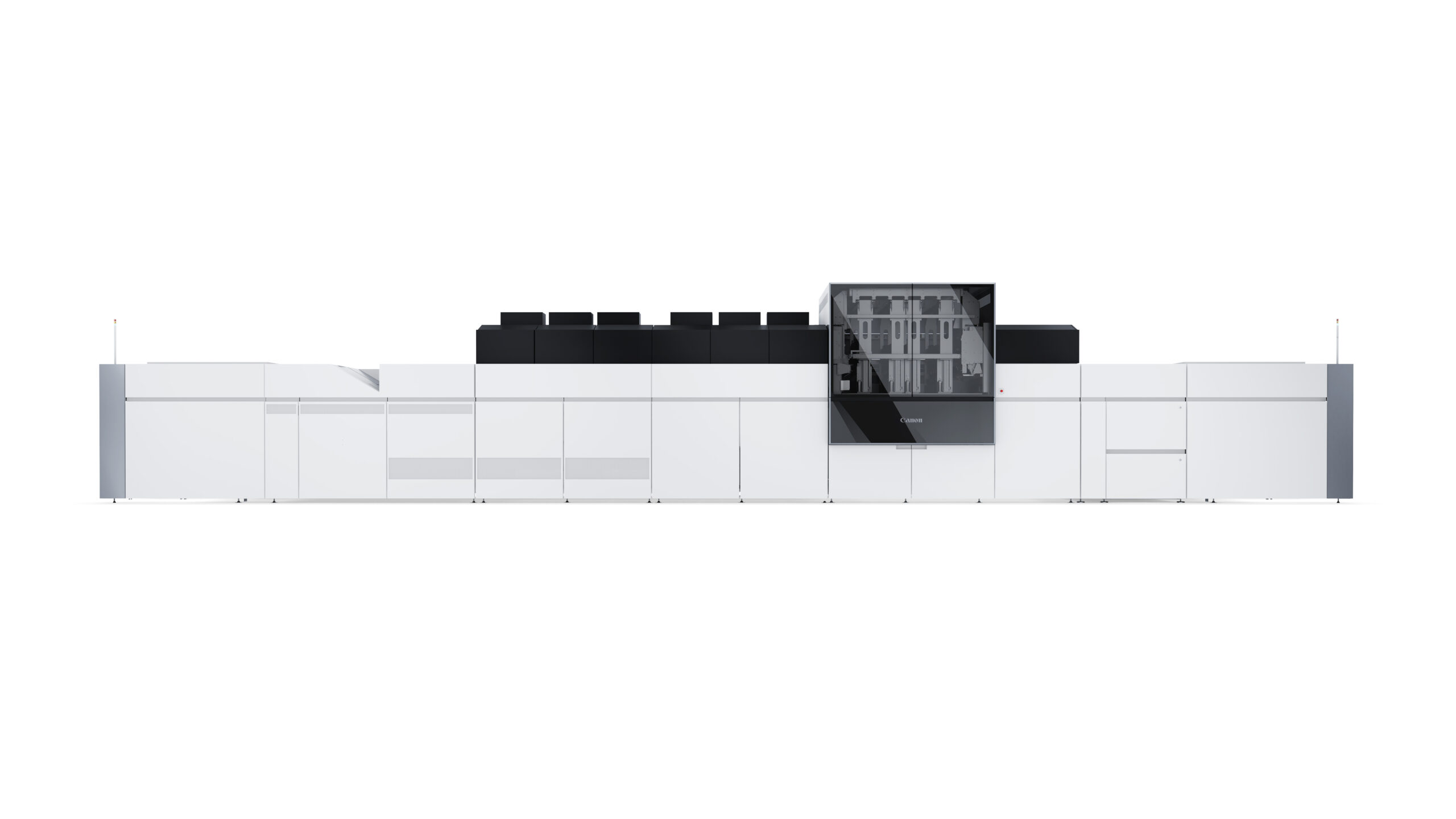

The new varioPRESS iV7

The iV7 press design follows the unit design of an established digital press. Sacrificing a compact footprint opens up several advantages, however. Besides the high-stack feeder, up to two paper tray modules can be added. This allows instant switching of papers or mixing papers in a job and users can load a new paper while the press is printing. Another advantage is a straight paper path – the sheets travel the whole length of the press in one plane, avoiding bending. Only when duplexing, the sheets are fed back at the bottom.

Interestingly Canon is using a new type of printhead in the press, a Canon Production Printing piezo inkjet head. This contrasts with the Kyocera piezo heads used in the web models and the varioPRINT iX. The heads are recirculating to improve nozzle health

The iV7 is a major step forward for Canon in inkjet technology, featuring a new press platform and inkjet heads. It could be stepping stone for Canon’s ambitions in packaging print. Also, a seven-colour version and added in-line finishing could follow. The iV7 more than doubles the speed compared to the iX-Series and, as a result, is closing the gap to the continuous feed models while giving high-volume users a choice between a web and cut-sheet workflow.